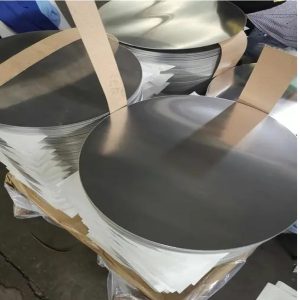

1100 Spinning aluminum circle Manufacturer and Supplier

A spinning aluminum circle is a circular piece of aluminum that is spun on a lathe to create a symmetrical shape. This process is known as metal spinning or spin forming.

The spinning process involves rotating the aluminum disc on a lathe while a tool is pressed against it, causing it to gradually form into a circular shape.

The resulting circle can be used for various applications such as cookware, lighting fixtures, and automotive parts.

The thickness and diameter of the circle can be customized based on the specific requirements of the application.

Aluminum is a popular material for spinning due to its lightweight, durability, and corrosion resistance.

Spinning aluminum circle is an aluminum product manufactured by spinning process and has a wide range of applications.

The spinning process is a metal processing method. Through the rotation and pressure of the spinning machine, the aluminum alloy material is gradually deformed under the action of the mold, and finally the required shape is obtained.

Spinning aluminum circles has many advantages, such as efficiency, precision and economy. Since the aluminum alloy material itself has the characteristics of light weight, high strength, and corrosion resistance, spinning aluminum circles can meet the needs of material performance in various fields.

In the field of automobile manufacturing, spinning aluminum circles can be used to manufacture automobile bodies, doors, roofs and other parts, helping to achieve the goals of automobile weight reduction, energy conservation and environmental protection.

In the aerospace field, spinning aluminum circles can be used to manufacture parts such as aircraft fuselages and airfoils, and have good mechanical properties and corrosion resistance.

In addition, in the construction field, spinning aluminum circles can be used to manufacture doors, windows, curtain walls, balconies and other building components to meet the building’s material performance and appearance requirements.

Spinning Aluminum Circle means aluminium circle used for spinning. It always use cold rolled aluminium discs which made by cutting aluminium coils with a cold rolling mill.

Common cold rolled round alloy A1050 1060 1070 1100 3003 3015 5052, etc., has good workability and corrosion resistance.

Aluminum Circles Product Specification:

- Alloy: 1050, 1060, 1070, 1100, 3002, 3003, 3004, 5052A, 5052, 5754, 6061

- Hardness: O, H12, H14, H16, H18

- Thickness: 0.012″ – 0.15″ (0.3mm – 4mm)

- Diameter: 3.94″ – 38.5″ (80mm -2000mm)

- Surface: Polished, Bright, Anodized

- Usage: Suitable for making pots, pans, pizza trays, pie pans, cake pans, covers, kettles, basins, fryers, light reflectors

- Stamping Materials Include: steel, galvanized steel, aluminum, aluminum alloy and other metals

A1050 aluminum discs are mainly composed of aluminum and contain small amounts of other alloying elements, which gives it high purity, good ductility, strength and toughness

A1050 aluminum discs are widely used in many fields due to their excellent performance. For example, it can be used to manufacture parts for automobiles, aviation, military and electronic products, such as car bodies, aircraft cabins, engine parts, military equipment and circuit boards, etc.

In addition, A1050 aluminum discs are also commonly used in the manufacture of daily necessities, lighting fixtures, reflective panels, decorations, chemical industry containers, heat sinks, signs and other products.

In these areas, the high ductility and strength of A1050 aluminum discs enable it to easily cope with various complex shapes and structural designs.

1070 aluminum disc is a circular sheet material processed from 1070 aluminum alloy. 1070 aluminum alloy has a series of excellent physical and chemical properties, such as low density, good electrical and thermal conductivity, excellent corrosion resistance, and good plastic processing properties.

The alloy is suitable for a variety of processing methods, including gas, TIG and spot welding, and can increase strength through cold deformation.

In applications, 1070 aluminum discs are widely used in many fields due to their unique properties.

In the field of electrical and electronics, it is often used in components such as wires, cables, transformers and electrolytic capacitor foils because of its excellent conductive properties.

In the chemical industry, its good corrosion resistance makes it an ideal choice for chemical equipment, storage tanks and pipelines.

At the same time, because 1070 aluminum alloy is easy to shape and process, it is also often used in the manufacturing of architectural decoration, aluminum alloy doors and windows, and other products.

1100 aluminum circle is a type of aluminum alloy that contains 99% aluminum and 1% other elements such as iron, silicon, copper, and zinc.

It is a soft and ductile material that is commonly used in various applications such as cookware, lighting reflectors, traffic signs, and chemical processing equipment.

The 1100 aluminum circle has excellent corrosion resistance, high thermal conductivity, and good electrical conductivity. It is also easy to form, weld, and machine, making it a popular choice for many industries.

Metal spinning, the asymmetrical rotational forming process for sheet metal. It is often used in furniture, lighting, tableware, aerospace, and other industries.

The spinning production process generally requires cold-rolled discs ( also named CC aluminum discs). Commonly used grades are: 1050, 1060, 1100, 3003, 5052, 8011. spinning can be divided into manual spinning and CNC spinning.

Manual Spinning: manual spinning forming process is an old forming method, with a short production cycle, high technical requirements, can be used on ordinary machine tools with a simple mold to manufacture complex-shaped parts, and can be suitable for steel, aluminum, copper, and other different metal materials, saving raw materials and tooling costs, shortening the processing time. The workers always use wood or metal to finish the spinning.

CNC spinning (Automatic spinning): CNC spinning forming is the use of CNC turning centers to achieve the various motion trajectories required for spinning, and the use of its trajectory changes to optimize the quality of the parts, while rolling against the die can also be processed directly on the CNC machine tool. Especially suitable for frequently updated products or mass production of the spin forming process to select the best process parameters and trajectory.

Aluminum circles applications: baking dishes, coffee pots, steamers, pans, sieve pots, bowls, wine containers, teapots, vases, frying pan

As a professional aluminum round sheet manufacturer,our factory will have good control on the grain size and elongation of the master roll of the aluminum coil to ensure the excellent deep punching and spinning performance of the aluminum round sheet, and effectively avoid bad phenomena such as orange peel pattern, ruffled edge and high ear-making rate that may occur in the later processing.

The alloy, state, and performance of the aluminum coil are strictly controlled and tested to ensure the accuracy and diversity of the supplied aluminum disks

Spinning aluminum circles, also known as spun aluminum circles. The process of spinning aluminum circles involves using a lathe to spin a flat disc of aluminum at high speeds while shaping it into a circular shape.

What are the specific application scenarios of spinning aluminum circles in automobile manufacturing?

The specific application scenarios of spinning aluminum circles in automobile manufacturing are very rich. Here are some major application examples:

Body parts: Spun aluminum discs or Spinning aluminum circles play an important role in automobile body manufacturing.

They can be used to make body panels, doors, roofs and other parts, which not only reduce the overall weight of the car, but also help improve fuel efficiency and vehicle performance.

Chassis components: In chassis systems, spun aluminum discs are also widely used to manufacture various parts. The lightweighting of these components helps improve the car’s handling and stability while reducing fuel consumption and emissions.

Engine and transmission system: Spinning aluminum circles also play an important role in the manufacture of engines. They can be used to manufacture engine components, such as turbine blades, turbine disks, etc., to improve engine efficiency and life.

In addition, in the transmission system, spun aluminum circles are also used to manufacture key components such as clutches and gearbox gears.

These components have high strength and good impact resistance, which help improve the transmission efficiency and reliability of the car.

Fuel and emissions systems: Spinning aluminum circles can also be used to manufacture components in fuel systems and emissions systems, such as fuel tanks, exhaust pipes, etc.

These components not only have excellent corrosion resistance, but also effectively resist erosion by fuel and emissions, ensuring the safe and stable operation of the car.

In addition, spinning aluminum circles can also be used in automobile manufacturing to manufacture sound insulation panels, cylinder blocks, wheel hubs and other parts to meet the automobile’s needs for lightweight, high strength and corrosion resistance.