China 5754 aluminum coil Manufacturer and Supplier | Ruiyi

5754 aluminum coil has the characteristics of medium strength, good corrosion resistance, weldability and easy processing and forming, and is a typical alloy in the Al-Mg alloy. 5754 aluminium–magnesium alloy is an alloy in the wrought aluminium -magnesium family (5000 or 5xxx series). It is closely related to the alloys 5154 and 5454.

As a wrought alloy, 5754 aluminum can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility.

5754 aluminum alloy is a typical Al-Mg alloy containing 2,6-3,6% magnesium. The addition of magnesium precipitates Mg2Si in the matrix to provide strengthening. The commonly used tempering states of materials are 5754-H111 and 5754 H22, H12, H14, H114, etc. Al 5754 has high strength resistance, excellent atmospheric and marine corrosion resistance, excellent weldability, and is suitable for anodic oxidation protection. 5754 aluminum alloy is widely used in automobile body panels and frames, railways, ships (plates), electric power, transportation tanks, chemicals, food, forging and other industrial fields. Before being used in the automotive and aerospace industries, this aluminum alloy must be anodized to have high microhardness

Alternate names and designations include AlMg3, 3.3535, and A95754. The alloy and its various tempers are covered by the following standards:

- ASTM B 209: Standard Specification for Aluminium and Aluminium-Alloy Sheet and Plate

- EN 485-2: Aluminium and aluminium alloys. Sheet, strip and plate. Mechanical properties

- EN 573-3: Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 754-2: Aluminium and aluminium alloys. Cold drawn rod/bar and tube. Mechanical properties

- ISO 6361: Wrought Aluminium and Aluminium Alloy Sheets, Strips and Plates

The alloy composition of 5754 aluminium is:

| Aluminium | Chromium | Copper | Iron | Magnesium | Manganese | Silicon | Titanium | Zinc | Residuals |

|---|---|---|---|---|---|---|---|---|---|

| 94.2% to 97.4% | < 0.3% | < 0.1% | < 0.4% | 2.6% to 3.6% | < 0.5% | < 0.4% | < 0.15% | < 0.2% | < 0.15% |

5754 has good formability when in the fully soft, annealed temper and can be work-hardened to fairy high strength levels. It is slightly stronger, but less ductile, than 5052 alloy. It is used in a multitude of engineering and automotive applications

Temper: F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114

Thickness:0.2-350mm

Width:30-2600mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5-10ton per size

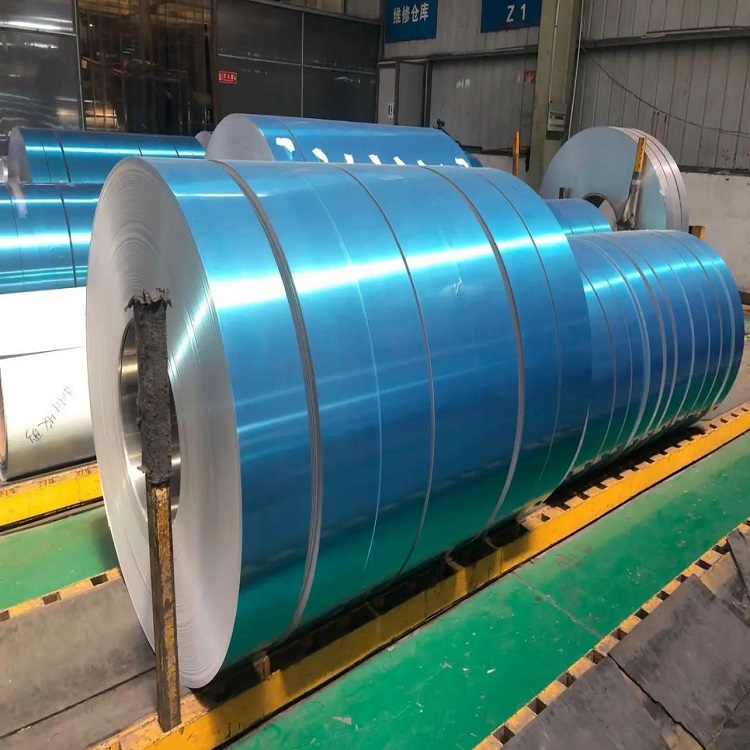

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209, EN573

Delivery time: about 30days after receiving the deposit

5754 aluminum alloy belongs to non-heat treatable 5000 series Al-Mg family. So, aluminum 5754 properties show excellent tread and anodizing quality, weldability, corrosion resistance especially to seawater, some chemical and polluted industrial environment. Besides, al 5754 mechanical properties are prominent in wrought aluminum. Such as tensile strength of 220 – 270 MPa. Therefore, 5754 aluminum alloy is widely used for marine, vehicle components, auto parts, welded structures, food industry, construction field, etc

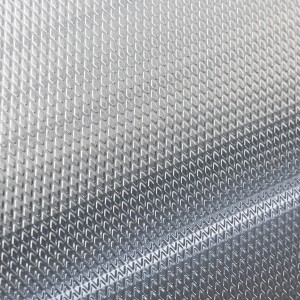

5754 aluminum alloy is widely used in tread plate, welding structure, ship structure and marine facilities, vehicle components, food processing, storage tank trailer, pressure vessel, rivets, window internal, treadplate, Shipbuilding, Vehicle bodies, Fishing industry equipment, Welded chemical and nuclear structures