Tuam Tshoj Ck75 Steel C75s C75 SAE 1075 caij nplooj ntoos hlav steel sawb

CK75 steel yog cov khoom siv high-carbon steel, nrog C qhia txog cov ntsiab lus carbon ntawm 0.75%. Lwm cov ntsiab lus tseem ceeb xws li manganese, silicon, phosphorus, thiab lwm yam.

CK75 Steel muaj cov khoom nram qab no thiab kev siv:

Yam ntxwv ntawm CK75 Steel:

Nws muaj zog yield zog thiab tensile zog thiab tuaj yeem tiv taus tensile loads loj.

Nws muaj cov khoom siv zoo thiab cov khoom siv kho cua sov, thiab tsim nyog rau kev tsim cov springs uas xav tau lub zog siab thiab hnav tsis kam.

Nws hardness tuaj yeem hloov kho los ntawm kev kho cua sov kom tau raws li qhov xav tau ntawm cov ntawv thov sib txawv.

Nws muaj qee yam sib nqus permeability thiab tuaj yeem siv los tsim cov khoom siv hluav taws xob.

Nws muaj kev tiv thaiv corrosion zoo thiab tuaj yeem tswj tau qhov chaw zoo thiab huab cua tsis kam nyob rau hauv qee yam mob.

Daim ntawv thov ntawm CK75 Steel:

Automotive kev lag luam: siv los tsim tsheb chassis springs thiab ncua kev kawm ntawv qhov system.

Machinery manufacturing: siv los tsim ntau yam khoom siv hluav taws xob, cov khoom siv kho tshuab thiab cov cuab yeej.

Cov khoom siv hluav taws xob thiab hluav taws xob: siv los tsim cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob.

Kev tsim kho thiab rooj tog zaum: siv los tsim qhov rooj thiab qhov rais kho vajtse accessories thiab rooj tog zaum, thiab lwm yam.

Haum rau kev ua cov springs loj heev, xws li stacked nplooj springs ntawm bulldozers, loj coil springs thiab loj torsion springs rau nkoj.

CK75 Steel yog sib npaug rauAISI 1075 carbon hlausuav nrog:

ASTM A29 (1075) Cov Lus Qhia

ASTM A510 (1075)

ASTM A713 (1075) Cov Lus Qhia Tshwj Xeeb

SAE J403 (1075)

SAE J412 (1075)

EN10132 Txheem SAE1075 txias dov carbon steel sawb CK75 ua C75 C75S Caij nplooj ntoos hlav steel sawb muaj cov ntsiab lus carbon ntawm 0.7-0.8% ua rau nws muaj ntau lub hom phiaj carbon steel nrog lub caij nplooj ntoos hlav zoo.

Yog li ntawd, nws yog ib qho nquag sivcarbon hlaunyob rau hauv ntau yam kev siv engineering.

SAE1075 los yog CK75 muaj 0.7-0.8% carbon, 0.15-0.35% silicon, 0.6-0.9% manganese, thiab 0.03% phosphorus thiab sulfur. Nws muaj lub zog tensile ntawm 1230-1340 MPa, yield zog ntawm 1130-1240 MPa, thiab hardness ntawm 57-63 HRC.

CK75 lub caij nplooj ntoos hlav hlau tau zoo dua hardenability, qhov tseem ceeb hardenable txoj kab uas hla hauv cov roj tuaj yeem ncav cuag 100 ~ 150mm.

CK75 los yog C75 yog tsim los ua cov springs loj heev, xws li stacked nplooj springs ntawm bulldozers, loj coil springs thiab loj torsion springs rau nkoj.

CK75 lub caij nplooj ntoos hlav steel yog cov khoom siv high-carbon steel. Nws cov tshuaj muaj pes tsawg leeg feem ntau suav nrog carbon (C) cov ntsiab lus ntawm 0.70-0.80%, silicon (Si) cov ntsiab lus ntawm 0.10-0.35%, thiab manganese (Mn) cov ntsiab lus ntawm 0.60-0.80%.

Ntawm 0.90%, cov ntsiab lus ntawm phosphorus (P) thiab sulfur (S) tsawg dua 0.025% feem.

CK75 lub caij nplooj ntoos hlav steel muaj zoo elasticity thiab toughness thiab feem ntau yog siv los tsim cov springs, hniav, saw hniav, riam thiab lwm yam khoom thiab cov cuab yeej uas yuav tsum tau muaj zog thiab hnav tsis kam.

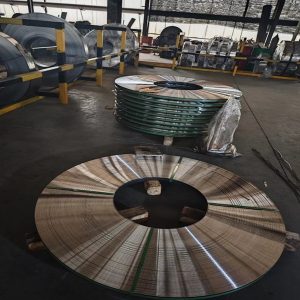

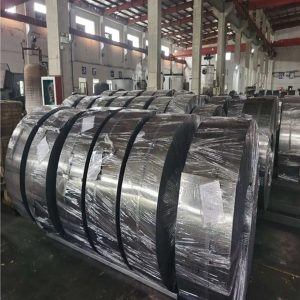

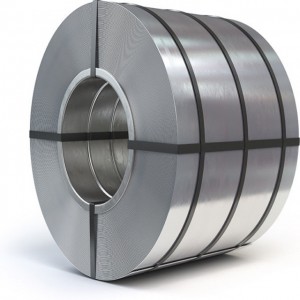

C75 C75s CK75 SAE 1075 caij nplooj ntoos hlav steel sawb

1, Kev Xa Khoom:

| Kev Xa Khoom | Qhov ntau thiab tsawg | Nto | Ntug |

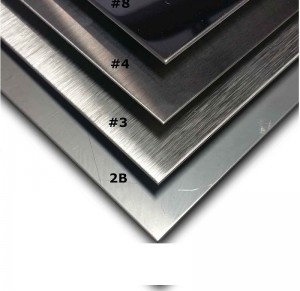

| 1.Cold Rolled | 1. Thickness: 0.09-8 hli | Bright / Polished / Blue/daj | Swb |

| 2.Cold Rolled + Hydrogen Annealed | 2. Dav: 6-450mm | Hloov | |

| 3.Cold Rolled + Hardened + Tempered | Coil sab hauv txoj kab uas hla: 300-800mm | Square |

2, Qib sib piv:

| GRADES PIB FOR SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | GERMANY DIN | FRANCE NF | BIRTAIN IB | ISO | KOREAKS | TAIWAN CNS |

| 45 | 1045 ib | S45 C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50 C | CK50 | XC50 | 080m 50 | C50 | ||

| 60 | 1060 | S60 C | CK60 | XC60 | 060a62 ua | C60 | ||

| 70 | 1070 | S70 C | CK 70 | XS 70 | S70 | |||

| 75 | 1075 ib | S75 C | CK75 ua | XC75 | C75 | |||

| T10 | W1-9 | SK 4 | ||||||

| T9 | W1-8 | SK 5 | ||||||

| TSI SK85 | — | TSI SK85 | ||||||

| 40 Mn | 1043 ib | SWB 42B | 40mn 4 | 40m5 ua | 080a40 ua | SL, SIB | ||

| 42mn ua | ||||||||

| 65mn ua | 1566 ib | S60C-CSP | ck67 ua | 080 ua 67 | C60E4 | |||

| 55 Si 2 Mn | ib 9255 | SUP 6 /SUP7 | 55 ib 7 | 55 ib 7 | 251h60 ib | 55 txc 7 | ||

| 60 Si2 Mn | ib 9260 | SUP 6 / SUP7 | 65 ib 7 | 65 ib 7 | 251h60 ib | 61 txc 7 | SUP 3 | SUP 6 |

| 62 Si 2 Mn | ||||||||

| 75cr 1 | 75cr 1 | 75cr 1 | 75cr 1 | |||||

| 51cwv 4 | 5 160 | SUP9A | 51cwv 4 | 51cwv 4 | SPS5A | SUP9A | ||

| 30 CrMo | g41300 ua | SUP13 | 35 CrMo4 | SPS 9 | SUP13 | |||

| 50 CrVA | 6 150 | SUP 10 | 51cwv 4 | 51cwv 4 | 735a51 ua | 51cwv 4 | SPS6 | SUP 10 |

3, Tshuaj muaj pes tsawg leeg:

| Txuj | Qib | Chemical Composition (%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | V | ||

| GB / T699 | 45 | 0.42-0.50 Nws | 0.17-0.37 Nws | 0.50-0.80 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T699 | 50 | 0.47-0.55 Nws | 0.17-0.37 Nws | 0.50-0.80 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T699 | 55 | 0.52-0.60 Nws | 0.17-0.37 Nws | 0.50-0.80 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T699 | 60 | 0.57-0.65 hli | 0.17-0.37 Nws | 0.50-0.80 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T699 | 65 | 0.62-0.70 Nws | 0.17-0.37 Nws | 0.50-0.80 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T699 | 70 | 0.67-0.75 Nws | 0.17-0.37 Nws | 0.50-0.80 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T699 | 75 | 0.72-0.80 Nws | 0.17-0.37 Nws | 0.50-0.80 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T699 | Mn 40 | 0.37-0.44 Nws | 0.17-0.37 Nws | 0.70—1.00 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T699 | Mn45 ua | 0.42-0.50 Nws | 0.17-0.37 Nws | 0.70—1.00 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T699 | Mn65 ua | 0.62-0.70 Nws | 0.17-0.37 Nws | 0.90-1.20 Nws | 0.035 ib | 0.035 ib | 0.25 | 0.3 | 0.25 | |

| GB / T1298 | SK85/SK 5 | 0.80 ~ 0.90 hli | ≤ 0.35 | ≤0.50 | 0.03 ib | 0.03 ib | 0.2 | 0.25 | 0.3 | |

| GB / T1298 | SK 4 | 0.95-1.04 Nws | ≤ 0.35 | ≤ 0.40 | 0.035 ib | 0.03 ib | 0.25 | 0.2 | 0.3 | |

| GB / T3077 | 51cwv 4 | 0.47-0.55 Nws | 0.17-0.37 Nws | 0.80-1.10 Nws | 0.035 ib | 0.035 ib | 0.90-1.20 Nws | 0.3 | 0.3 | 0.10-0.20 Nws |

| GB / T3077 | 50 CrVA | 0.47 ~ 0.54 hli | 0.17-0.37 Nws | 0.50-0.80 Nws | 0.025 ib | 0.025 ib | 0.80-1.10 Nws | 0.3 | 0.3 | 0.10-0.20 Nws |

| GB / T3077 | 75cr 1 | 0.7-0.8 hli | 0.25 ~ 0.5 hli | 0.50-0.70 Nws | 0.035 ib | 0.035 ib | 0.30-0.40 Nws | |||

| GB / T1222 | 55 Si 2 Mn | 0.52-0.60 Nws | 1.50—2.00 Nws | 0.60-0.90 Nws | ≤ 0.035 | ≤ 0.035 | ≤ 0.35 | ≤ 0.35 | ≤ 0.25 | |

| GB / T1222 | 60 ib 2mn | 0.56-0.64 hli | 1.50—2.00 Nws | 0.60-0.90 Nws | ≤ 0.035 | ≤ 0.035 | ≤ 0.35 | ≤ 0.35 | ≤ 0.25 | |