Lachin Ck75 Steel C75s C75 SAE 1075 teren asye prentan

CK75 asye se yon materyèl asye ki gen anpil kabòn, ak C ki endike yon kontni kabòn nan 0.75%. Lòt eleman alyaj prensipal yo enkli Manganèz, Silisyòm, fosfò, elatriye.

CK75 Steel la gen pwopriyete ak aplikasyon sa yo:

Karakteristik CK75 Steel:

Li gen gwo fòs sede ak fòs rupture epi li ka kenbe tèt ak gwo chaj rupture.

Li gen bon pwopriyete mekanik ak pwopriyete tretman chalè, epi li apwopriye pou manifakti sous dlo ki mande pou gwo fòs ak rezistans mete.

Dite li yo ka ajiste nan tretman chalè pou satisfè bezwen diferan senaryo aplikasyon.

Li gen yon sèten pèmeyabilite mayetik epi li ka itilize pou fabrike eleman elektwomayetik.

Li gen bon rezistans korozyon epi li ka kenbe bon sifas fini ak rezistans move tan nan sèten kondisyon.

Aplikasyon CK75 Steel:

Endistri otomobil: itilize pou fabrike sous dlo chasi otomobil ak pati sistèm sispansyon.

Manifakti machin: itilize pou fabrike divès kalite sous mekanik, pati mekanik ak zouti.

Jaden elektwonik ak elektrik: yo itilize pou fabrike konpozan elektwomayetik ak sous kondiktif.

Konstriksyon ak mèb: yo itilize pou fabrike akseswa pyès ki nan konpitè pòt ak fenèt yo ak sous dlo mèb, elatriye.

Apwopriye pou fè sous dlo gwo anpil, tankou sous fèy anpile sou bouteur, gwo sous dlo bobin ak gwo sous torsion sou bato.

CK75 Steel yo ekivalan aAISI 1075 kabòn asyeenkli:

ASTM A29 (1075)

ASTM A510 (1075)

ASTM A713 (1075)

SAE J403 (1075)

SAE J412 (1075)

EN10132 Creole SAE1075 frèt woule kabòn asye teren CK75 C75 C75S Spring asye teren gen yon kontni kabòn nan 0.7-0.8% fè li yon asye kabòn milti-bi ak pwopriyete prentan bon.

Se poutèt sa, li se yon souvan itilizeasye kabònnan yon pakèt aplikasyon jeni.

SAE1075 oswa CK75 gen 0.7-0.8% kabòn, 0.15-0.35% Silisyòm, 0.6-0.9% Manganèz, ak 0.03% fosfò ak souf. Li gen yon fòs rupture nan 1230-1340 MPa, fòs sede nan 1130-1240 MPa, ak yon dite nan 57-63 HRC.

CK75 prentan asye gen pi bon hardenability, dyamèt la difisil hardenable nan lwil oliv ka rive nan 100 ~ 150mm.

CK75 oswa C75 se Apwopriye pou fè sous dlo trè gwo, tankou sous dlo fèy anpile sou bouteur, gwo sous dlo bobin ak gwo sous torsion sou bato.

CK75 asye prentan se yon materyèl asye ki gen anpil kabòn. Konpozisyon chimik li yo sitou gen ladan kontni kabòn (C) ant 0.70-0.80%, kontni Silisyòm (Si) ant 0.10-0.35%, ak kontni Manganèz (Mn) ant 0.60-0.80%.

Ant 0.90%, sa ki nan fosfò (P) ak souf (S) se mwens pase 0.025% respektivman.

Asye prentan CK75 gen bon elastisite ak severite epi li souvan itilize pou fabrike sous dlo, lam, lam wè, kouto ak lòt pati ak zouti ki mande pou gwo fòs ak rezistans mete.

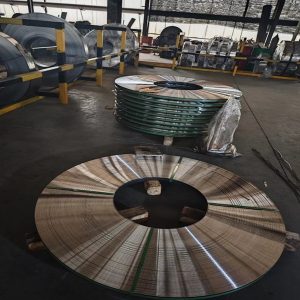

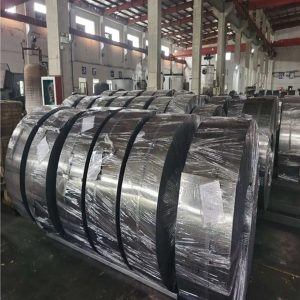

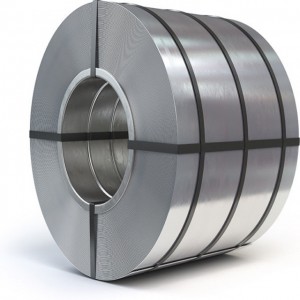

C75 C75s CK75 SAE 1075 sezon prentan asye teren

1, Kondisyon livrezon:

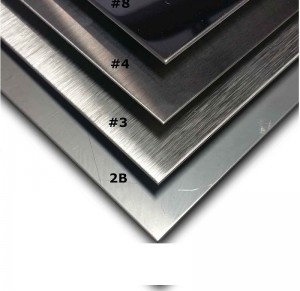

| Kondisyon Livrezon | Gwosè | Sifas | Edge |

| 1.Fwad woule | 1.Epesè: 0.09-8mm | Klere / Poli / Ble/Jòn | Fant |

| 2.Frèt woule + Idwojèn annealed | 2.Lajè: 6-450mm | Round | |

| 3.Frèt woule+fè tèt di+tanperaman | Dyamèt inisye bobin: 300-800mm | Kare |

2, konparezon klas:

| KONPARAZ KLAS pou PRANT ASTE | ||||||||

| CHINA GB/T | USA ASTM | JAPON JIS | ALLEMAG DIN | FRANS NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | — | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL,SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3, konpozisyon chimik:

| Estanda | Klas | Konpozisyon chimik(%) | ||||||||

| C | Si | Mn | P | S | Kr | Ni | Cu | V | ||

| GB/T699 | 45 | 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47~0.55 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52~0.60 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57~0.65 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62~0.70 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67~0.75 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72~0.80 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37~0.44 | 0.17~0.37 | 0.70~1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42~0.50 | 0.17~0.37 | 0.70~1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62~0.70 | 0.17~0.37 | 0.90~1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95~1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47~0.55 | 0.17~0.37 | 0.80~1.10 | 0.035 | 0.035 | 0.90~1.20 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 50CrVA | 0.47~0.54 | 0.17~0.37 | 0.50~0.80 | 0.025 | 0.025 | 0.80~1.10 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 75Cr1 | 0.7 ~ 0.8 | 0.25 ~ 0.5 | 0.50~0.70 | 0.035 | 0.035 | 0.30~0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52~0.60 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56~0.64 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |