China Ck75 Steel C75s C75 SAE 1075 mmiri ígwè warara

CK75 steel bụ ihe igwe nwere nnukwu carbon, yana C na-egosi ọdịnaya carbon nke 0.75%. Ndị ọzọ bụ isi alloying gụnyere manganese, silicon, phosphorus, wdg.

Steel CK75 nwere akụrụngwa na ngwa ndị a:

Njirimara nke CK75 Steel:

Ọ nwere ike mkpụrụ dị elu na ike nkwụsịtụ ma nwee ike iguzogide nnukwu ibu nkwụsị.

Ọ nwere ezigbo ihe eji arụ ọrụ na ihe ọgwụgwọ okpomọkụ, ọ dịkwa mma maka ịmepụta isi iyi nke chọrọ ike dị elu ma na-eyi nguzogide.

Enwere ike imezi ike ya site na ọgwụgwọ okpomọkụ iji gboo mkpa nke ngwa ngwa dị iche iche.

Ọ nwere ụfọdụ ike ndọta ma enwere ike iji ya rụpụta ihe ndị na-ahụ maka elektrọnik.

Ọ nwere ezigbo nguzogide corrosion ma nwee ike ịnọgide na-emecha elu elu yana nguzogide ihu igwe n'okpuru ọnọdụ ụfọdụ.

Ngwa nke CK75 Steel:

Ụlọ ọrụ ụgbọ ala: eji arụpụta isi iyi chassis ụgbọ ala yana akụkụ sistemu nkwusioru.

Imepụta igwe: eji arụpụta isi iyi mmiri dị iche iche, akụkụ igwe na ngwaọrụ.

Ebe eletrọnịkị na eletrọnịkị: a na-eji emepụta ihe ndị na-emepụta ihe na mmiri na-eduzi.

Ihe owuwu na arịa ụlọ: eji emepụta ngwa ngwa ọnụ ụzọ na windo na isi iyi arịa ụlọ, wdg.

Kwesịrị ekwesị maka ịmepụta nnukwu isi iyi, dị ka isi iyi akwụkwọ ndị a chịkọtara n'elu bulldozers, nnukwu isi iyi mmiri na nnukwu mmiri mmiri n'elu ụgbọ mmiri.

CK75 igwe dakọtaraAISI 1075 carbon ígwègụnyere:

ASTM A29 (1075)

ASTM A510 (1075)

ASTM A713 (1075)

SAE J403 (1075)

SAE J412 (1075)

EN10132 Standard SAE1075 oyi akpọrepu carbon ígwè warara CK75 C75 C75S Spring ígwè warara nwere carbon ọdịnaya nke 0.7-0.8% na-eme ka ọ a multi-nzube carbon ígwè nwere ezi mmiri Njirimara.

Ya mere, a na-ejikarị ya eme ihecarbon ígwèn'ọtụtụ ngwa injinia.

SAE1075 ma ọ bụ CK75 nwere 0.7-0.8% carbon, 0.15-0.35% silicon, 0.6-0.9% manganese, na 0.03% phosphorus na sọlfọ. Ọ nwere ike nkwụsi ike nke 1230-1340 MPa, ike nke 1130-1240 MPa, yana isi ike nke 57-63 HRC.

CK75 mmiri ígwè nwere mma hardenability, oké egwu hardenable dayameta na mmanụ nwere ike iru 100 ~ 150mm.

CK75 ma ọ bụ C75 dabara adaba maka ịme nnukwu isi iyi, dị ka isi iyi akwụkwọ mgbokwasị na bulldozers, nnukwu mmiri iyi na nnukwu mmiri mmiri torsion na ụgbọ mmiri.

CK75 spring steel bụ ihe igwe nwere carbon dị elu. Ngwakọta kemịkalụ ya na-agụnye ọdịnaya carbon (C) n'etiti 0.70-0.80%, ọdịnaya silicon (Si) dị n'etiti 0.10-0.35%, yana ọdịnaya manganese (Mn) dị n'etiti 0.60-0.80%.

N'etiti 0.90%, ọdịnaya nke phosphorus (P) na sọlfọ (S) erughị 0.025% n'otu n'otu.

Igwe mmiri CK75 nwere ezigbo ngbanwe na ịdị ike ma na-ejikarị emepụta isi iyi, agụba, agụba, mma na akụkụ ndị ọzọ na ngwaọrụ chọrọ ike dị elu ma na-eyi nguzogide.

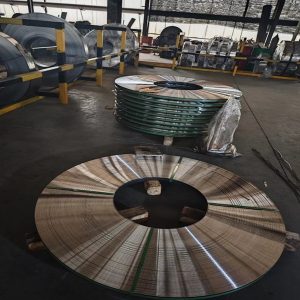

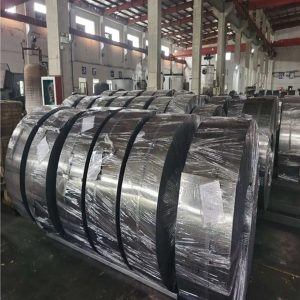

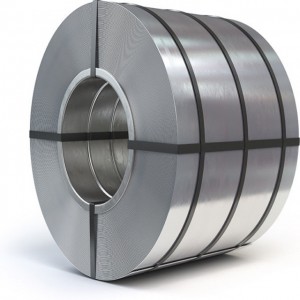

C75 C75s CK75 SAE 1075 mmiri ígwè warara

1, Ọnọdụ nnyefe:

| Ọnọdụ nnyefe | Nha | Elu | Ọnụ |

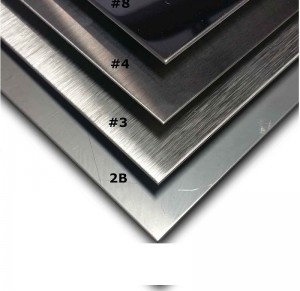

| 1.Oyi Akpọrọ | 1. Ọkpụrụkpụ: 0.09-8mm | Na-egbuke egbuke / Na-egbu maramara / Blue/Yellow | Ibewa |

| 2.Oyi Rolled+Hydrogen Annealed | 2. Obosara: 6-450mm | Gburugburu | |

| 3.Oyi na-akpọgharị+Ejisie ike+Oyi | Dayameta eriri igwe insider: 300-800mm | Square |

2, Ntụnyere akara ule:

| GRADES tụnyere maka SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | GERMANY DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | - | SK85 | ||||||

| 40 nde | 1043 | SWRH42B | 40 nde 4 | 40M5 | 080A40 | SL, SM | ||

| 42Nn | ||||||||

| 65 nde | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3, Ngwakọta kemịkalụ:

| Ọkọlọtọ | Ọkwa | Ngwakọta kemịkalụ (%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Ku | V | ||

| GB/T699 | 45 | 0.42 ~ 0.50 | 0.17 ~ 0.37 | 0.50 ~ 0.80 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47 ~ 0.55 | 0.17 ~ 0.37 | 0.50 ~ 0.80 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52 ~ 0.60 | 0.17 ~ 0.37 | 0.50 ~ 0.80 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57 ~ 0.65 | 0.17 ~ 0.37 | 0.50 ~ 0.80 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62 ~ 0.70 | 0.17 ~ 0.37 | 0.50 ~ 0.80 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67 ~ 0.75 | 0.17 ~ 0.37 | 0.50 ~ 0.80 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72 ~ 0.80 | 0.17 ~ 0.37 | 0.50 ~ 0.80 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37 ~ 0.44 | 0.17 ~ 0.37 | 0.70 ~ 1.00 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42 ~ 0.50 | 0.17 ~ 0.37 | 0.70 ~ 1.00 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62 ~ 0.70 | 0.17 ~ 0.37 | 0.90 ~ 1.20 | 0,035 | 0,035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95 ruo 1.04 | ≤0.35 | ≤0.40 | 0,035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47 ~ 0.55 | 0.17 ~ 0.37 | 0.80 ~ 1.10 | 0,035 | 0,035 | 0.90 ~ 1.20 | 0.3 | 0.3 | 0.10 ~ 0.20 |

| GB/T3077 | 50CrVA | 0.47 ~ 0.54 | 0.17 ~ 0.37 | 0.50 ~ 0.80 | 0.025 | 0.025 | 0.80 ~ 1.10 | 0.3 | 0.3 | 0.10 ~ 0.20 |

| GB/T3077 | 75Cr1 | 0.7 ~ 0.8 | 0.25 ~ 0.5 | 0.50 ~ 0.70 | 0,035 | 0,035 | 0.30 ~ 0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52 ~ 0.60 | 1.50 ~ 2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56 ~ 0.64 | 1.50 ~ 2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |