China Ck75 Steel C75s C75 SAE 1075 spring steel strip

Baja CK75 minangka bahan baja karbon dhuwur, kanthi C nuduhake kandungan karbon 0,75%. Unsur paduan utama liyane kalebu mangan, silikon, fosfor, lsp.

Baja CK75 nduweni sifat lan aplikasi ing ngisor iki:

Karakteristik Baja CK75:

Wis kekuatan ngasilaken dhuwur lan kekuatan tensile lan bisa tahan beban tensile gedhe.

Nduwe sifat mekanik sing apik lan sifat perawatan panas, lan cocok kanggo manufaktur sumber sing mbutuhake kekuatan dhuwur lan tahan nyandhang.

Kekerasane bisa diatur liwat perawatan panas kanggo nyukupi kabutuhan skenario aplikasi sing beda.

Nduwe permeabilitas magnetik tartamtu lan bisa digunakake kanggo nggawe komponen elektromagnetik.

Nduwe ketahanan korosi sing apik lan bisa njaga permukaan sing apik lan tahan cuaca ing kahanan tartamtu.

Aplikasi baja CK75:

Industri otomotif: digunakake kanggo nggawe sumber sasis mobil lan bagean sistem suspensi.

Manufaktur mesin: digunakake kanggo nggawe macem-macem sumber mekanik, bagean lan alat mekanik.

Bidang elektronik lan listrik: digunakake kanggo nggawe komponen elektromagnetik lan sumber konduktif.

Konstruksi lan Furnitur: digunakake kanggo Pabrik aksesoris hardware lawang lan jendhela lan spring Furnitur, etc.

Cocog kanggo nggawe mata air sing gedhe banget, kayata mata air sing ditumpuk ing buldoser, mata air kumparan gedhe lan mata air torsi gedhe ing kapal.

Baja CK75 setara karoBaja karbon AISI 1075kalebu:

ASTM A29 (1075)

ASTM A510 (1075)

ASTM A713 (1075)

SAE J403 (1075)

SAE J412 (1075)

EN10132 Standar SAE1075 cold rolled strip baja karbon CK75 C75 C75S Spring baja strip nduweni kandungan karbon 0,7-0,8% nggawe baja karbon multi-tujuan kanthi sifat musim semi sing apik.

Mulane, iku umume digunakakebaja karboning sawetara saka sudhut aplikasi engineering.

SAE1075 utawa CK75 ngandhut 0,7-0,8% karbon, 0,15-0,35% silikon, 0,6-0,9% mangan, lan 0,03% fosfor lan belerang. Iki nduweni kekuatan tarik 1230-1340 MPa, kekuatan ngasilake 1130-1240 MPa, lan kekerasan 57-63 HRC.

baja spring CK75 wis hardenability luwih, diameteripun hardenable kritis ing lenga bisa tekan 100 ~ 150mm.

CK75 utawa C75 Cocog kanggo nggawe mata air sing gedhe banget, kayata mata air sing ditumpuk ing buldoser, mata air kumparan gedhe lan mata air torsi gedhe ing kapal.

Baja spring CK75 minangka bahan baja karbon dhuwur. Komposisi kimia utamane kalebu kandungan karbon (C) antara 0,70-0,80%, kandungan silikon (Si) antara 0,10-0,35%, lan kandungan mangan (Mn) antara 0,60-0,80%.

Antarane 0,90%, isi fosfor (P) lan belerang (S) kurang saka 0,025%.

baja spring CK75 wis kelenturan apik lan kateguhan lan asring digunakake kanggo Pabrik springs, glathi, saw glathi, lading lan bagean liyane lan pribadi sing mbutuhake kekuatan dhuwur lan nyandhang resistance.

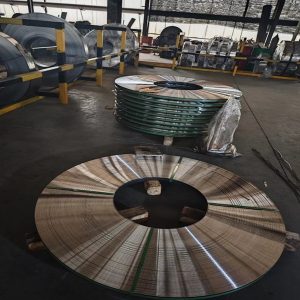

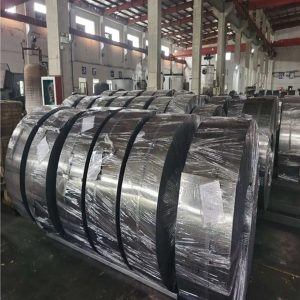

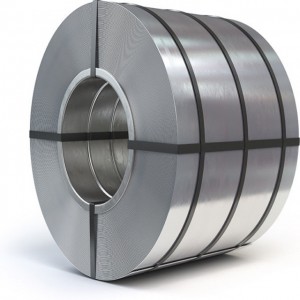

C75 C75s CK75 SAE 1075 strip baja pegas

1, Ketentuan Pangiriman:

| Kahanan Pangiriman | Ukuran | lumahing | Pinggir |

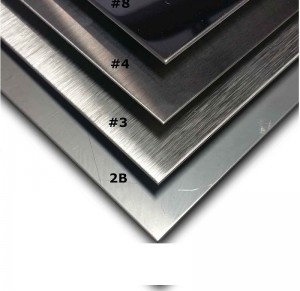

| 1. Cold Rolled | 1. Ketebalan: 0.09-8mm | Padhang / Poles / Biru/Kuning | irisan |

| 2. Cold Rolled + Hidrogen Anil | 2. Jembar: 6-450mm | Babak | |

| 3. Cold Rolled + Hardened + Tempered | Diameter njero kumparan: 300-800mm | kothak |

2, Perbandingan kelas:

| PERBANDINGAN GRADE KAnggo SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | JERMAN DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | — | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL, SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3, komposisi kimia:

| Standar | sasmita | Komposisi Kimia (%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | V | ||

| GB/T699 | 45 | 0,42~0,50 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47-0.55 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0,52~0,60 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0,57-0,65 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0,62-0,70 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67-0.75 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0,72~0,80 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37-0.44 | 0.17~0.37 | 0.70-1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0,42~0,50 | 0.17~0.37 | 0.70-1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0,62-0,70 | 0.17~0.37 | 0.90~1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0,80 ~0,90 | ≤0.35 | ≤0,50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95~1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47-0.55 | 0.17~0.37 | 0.80~1.10 | 0.035 | 0.035 | 0.90~1.20 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 50CrVA | 0.47-0.54 | 0.17~0.37 | 0,50-0,80 | 0,025 | 0,025 | 0.80~1.10 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 75Cr1 | 0.7-0.8 | 0,25~0,5 | 0,50-0,70 | 0.035 | 0.035 | 0.30-0.40 | |||

| GB/T1222 | 55Si2Mn | 0,52~0,60 | 1.50-2.00 | 0,60-0,90 | ≤0,035 | ≤0,035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0,56-0,64 | 1.50-2.00 | 0,60-0,90 | ≤0,035 | ≤0,035 | ≤0.35 | ≤0.35 | ≤0.25 | |