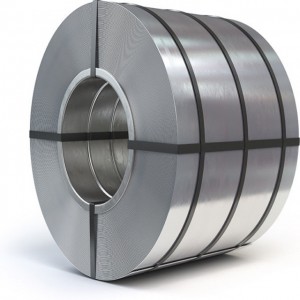

China EN10132 Standar SAE1075 cold rolled strip baja karbon CK75 C75 C75S Strip baja Spring Produsen lan Supplier | Ruiyi

EN10132 Standar SAE1075 cold rolled strip baja karbonCK75C75C75S Spring baja strip nduweni kandungan karbon 0,7-0,8% nggawe baja karbon multi-tujuan kanthi sifat musim semi sing apik. Mulane, iku baja karbon sing umum digunakake ing sawetara saka sudhut aplikasi engineering.

SAE 1075 utawaCK75ngandhut 0,7-0,8% karbon, 0,15-0,35% silikon, 0,6-0,9% mangan, lan 0,03% fosfor lan belerang. Iki nduweni kekuatan tarik 1230-1340 MPa, kekuatan ngasilake 1130-1240 MPa, lan kekerasan 57-63 HRC.

baja spring CK75 wis hardenability luwih, diameteripun hardenable kritis ing lenga bisa tekan 100 ~ 150mm. CK75 utawa C75 Cocog kanggo nggawe mata air sing gedhe banget, kayata mata air sing ditumpuk ing buldoser, mata air kumparan gedhe lan mata air torsi gedhe ing kapal.

Baja spring CK75 minangka bahan baja karbon dhuwur. Komposisi kimia utamane kalebu kandungan karbon (C) antara 0,70-0,80%, kandungan silikon (Si) antara 0,10-0,35%, lan kandungan mangan (Mn) antara 0,60-0,80%. Antarane 0,90%, isi fosfor (P) lan belerang (S) kurang saka 0,025%. baja spring CK75 wis kelenturan apik lan kateguhan lan asring digunakake kanggo Pabrik springs, glathi, saw glathi, lading lan bagean liyane lan pribadi sing mbutuhake kekuatan dhuwur lan nyandhang resistance.

C75 C75s CK75 SAE 1075 strip baja pegas

1, Ketentuan Pangiriman:

| Kahanan Pangiriman | Ukuran | lumahing | Pinggir |

| 1. Cold Rolled | 1. Ketebalan: 0.09-8mm | Padhang / Poles / Biru/Kuning | irisan |

| 2. Cold Rolled + Hidrogen Anil | 2. Jembar: 6-450mm | Babak | |

| 3. Cold Rolled + Hardened + Tempered | Diameter njero kumparan: 300-800mm | kothak |

2, Perbandingan kelas:

| PERBANDINGAN GRADE KAnggo SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | JERMAN DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | — | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL, SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3, komposisi kimia:

| Standar | sasmita | Komposisi Kimia (%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | V | ||

| GB/T699 | 45 | 0,42~0,50 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47-0.55 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0,52~0,60 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0,57-0,65 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0,62-0,70 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67-0.75 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0,72~0,80 | 0.17~0.37 | 0,50-0,80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37-0.44 | 0.17~0.37 | 0.70-1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0,42~0,50 | 0.17~0.37 | 0.70-1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0,62-0,70 | 0.17~0.37 | 0.90~1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0,80 ~0,90 | ≤0.35 | ≤0,50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95~1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47-0.55 | 0.17~0.37 | 0.80~1.10 | 0.035 | 0.035 | 0.90~1.20 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 50CrVA | 0.47-0.54 | 0.17~0.37 | 0,50-0,80 | 0,025 | 0,025 | 0.80~1.10 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 75Cr1 | 0.7-0.8 | 0,25~0,5 | 0,50-0,70 | 0.035 | 0.035 | 0.30-0.40 | |||

| GB/T1222 | 55Si2Mn | 0,52~0,60 | 1.50-2.00 | 0,60-0,90 | ≤0,035 | ≤0,035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0,56-0,64 | 1.50-2.00 | 0,60-0,90 | ≤0,035 | ≤0,035 | ≤0.35 | ≤0.35 | ≤0.25 | |

4, Toleransi Kita:

| TOLERNACES KETEBAL | |||||||

| Ketebalan Nominal (mm) | W < 125 | 125 <= W | |||||

| A | B | C | A | B | C | ||

| 0,15~0,25 | TS EN | ± 0,015 | ± 0,012 | ± 0,008 | ± 0,020 | ± 0,015 | ± 0,010 |

| Top Metal STEEL | ± 0,008 | ± 0,010 | |||||

| 0,25~0,40 | TS EN | ± 0,020 | ± 0,015 | ± 0,010 | ± 0,025 | ± 0,020 | ± 0,012 |

| Top Metal STEEL | ± 0,010 | ± 0,012 | |||||

| 0,40~0,60 | TS EN | ± 0,025 | ± 0,020 | ± 0,012 | ± 0,030 | ± 0,025 | ± 0,015 |

| Top Metal STEEL | ± 0,015 | ± 0,015 | |||||

| 0,60~1,00 | TS EN | ± 0,030 | ± 0,025 | ± 0,015 | ± 0,035 | ± 0,030 | ± 0,020 |

| Top Metal STEEL | ± 0,015 | ± 0,020 | |||||

| 1,00~1,50 | TS EN | ± 0,035 | ± 0,030 | ± 0,020 | ± 0,040 | ± 0,035 | ± 0,025 |

| Top Metal STEEL | ± 0,020 | ± 0,025 | |||||

| 1,50~2,50 | TS EN | ± 0,040 | ± 0,035 | ± 0,025 | ± 0,050 | ± 0,040 | ± 0,030 |

| Top Metal STEEL | ± 0,025 | ± 0,030 | |||||

| 2,50~4,00 | TS EN | ± 0,050 | ± 0,040 | ± 0,030 | ± 0,060 | ± 0,050 | ± 0,035 |

| Top Metal STEEL | ± 0,030 | ± 0,035 | |||||

| Hubungi kita yen sampeyan duwe syarat khusus. | |||||||

| TOLERANSI WIDTH FOR SLIT EDGE (GK) | |||||||

| Toleransi Jembar TS EN 10140 | Lebar produksi (mm) | ||||||

| Ketebalan Nominal (mm) | W < 125 | 125 <= W <= 250 | 250 < W | ||||

| A | B | A | B | A | B | ||

| 0,2 ~ 0,6 | TS EN | ± 0,15 | ± 0,10 | ± 0,20 | ± 0,13 | ± 0,25 | ± 0,18 |

| TOP BAJA LOGAM | ± 0,10 | ± 0,13 | ± 0,18 | ||||

| 0,6 ~ 1,5 | TS EN | ± 0,20 | ± 0,13 | ± 0,25 | ± 0,18 | ± 0,30 | ± 0,20 |

| TOP BAJA LOGAM | ± 0,13 | ± 0,18 | ± 0,20 | ||||

| 1,5 ~ 2,5 | TS EN | ± 0,25 | ± 0,18 | ± 0,30 | ± 0,20 | ± 0,35 | ± 0,25 |

| TOP BAJA LOGAM | ± 0,18 | ± 0,20 | ± 0,25 | ||||

| 2,5 ~ 4,0 | TS EN | ± 0,30 | ± 0,20 | ± 0,35 | ± 0,25 | ± 0,40 | ± 0,30 |

| TOP BAJA LOGAM | ± 0,20 | ± 0,25 | ± 0,30 | ||||

5, Aplikasi:

| Standar produk | Aplikasi | S50C(CK50/1050) | - Pita pengukur | |

| 65Si2Mn | – Springs | - Bagean struktural kamera | ||

| 50CrV4 | – Springs | - Bagean rantai | ||

| 51CrV4 | – Springs | – Springs | ||

| SK4 (1095) | - Pita pengukur | - Bagian kopling | ||

| – Pisau cukur | - Tukang cuci | |||

| - Titik pena | - Gesper safety | |||

| - Sumber angin | S55C(CK55/1050) | – Springs | ||

| – Springs | - Sepatu safety | |||

| – Cutlery | - Pembuka kaleng | |||

| - Jarum nyulam | - Pisau Thompson | |||

| SK5 (1085) | - Pita pengukur | - Bagean struktural kamera | ||

| - Gauge | S60C(CK60/1060) | - Bagean rantai | ||

| – Springs | – Gergaji tangan kanggo gawe kayu | |||

| – Cutlery | - Sepatu safety | |||

| - Jarum nyulam | – Springs | |||

| – Band saws kanggo woodworking | - Bagian peralatan kantor | |||

| lan lumbering | - Tukang cuci | |||

| - Gergaji bunder | S65C(65MN/CK67) | - Sepatu safety | ||

| - Bagian peralatan kantor | - Bagian kopling | |||

| S45C(CK45/1045) | - Bagian kopling | – Springs | ||

| - Bagean rantai | - Tukang cuci | |||

| - Retainers | S75C(CK75/1075) | - Bagian kopling | ||

| - Tukang cuci | – Springs | |||

| S50C(CK50/1050) | - Pita pengukur | - Band saws | ||

| - Bagean struktural kamera |