Haina Ck75 Steel C75s C75 SAE 1075 puna tira maitai

Ko te maitai CK75 he rawa waro teitei, me te C e tohu ana i te ihirangi waro o te 0.75%. Ko etahi atu waahanga whakauru matua ko te konupora, te silicon, te ūkuikui, aha atu.

Kei te CK75 Steel nga ahuatanga me nga tono e whai ake nei:

Te ahua o te CK75 Steel:

He nui te kaha o te tuku me te kaha kaha, ka taea e ia te tu atu i nga taumahatanga nui.

He pai nga ahuatanga miihini me nga ahuatanga maimoatanga wera, a he pai mo te hanga i nga puna e hiahia ana kia kaha te kaha me te mau kakahu.

Ka taea te whakatika i tona pakeke ma te maimoatanga wera ki te whakatutuki i nga hiahia o nga ahuatanga tono rereke.

Kei a ia tetahi uruhanga autō ka taea te whakamahi ki te hanga i nga waahanga hiko.

He pai te aukati waikura, ka taea te pupuri i te pai o te mata me te aukati huarere i raro i etahi ahuatanga.

Taupānga o CK75 Steel:

Ahumahi Automotive: whakamahia ki te hanga puna chassis waka me nga waahanga punaha whakatārewatanga.

Te hanga miihini: whakamahia ki te hanga i nga momo puna miihini, nga waahanga miihini me nga taputapu.

Nga waahi hiko me te hiko: whakamahia hei hanga i nga waahanga hiko me nga puna hiko.

Te hanga me nga taonga: whakamahia hei hanga taputapu taputapu tatau me te matapihi me nga puna taonga, aha atu.

He pai mo te hanga i nga puna nui rawa, penei i nga puna rau rau i runga i nga bulldozers, nga puna porowhita nui me nga puna toronga nui ki runga kaipuke.

CK75 Steel he rite kiAISI 1075 waro maitaingā:

ASTM A29 (1075)

ASTM A510 (1075)

ASTM A713 (1075)

SAE J403 (1075)

SAE J412 (1075)

EN10132 Paerewa SAE1075 takai maeke waro maitai takai CK75 C75 C75S Spring takai maitai he waro waro o te 0.7-0.8% ka waiho hei maitai waro whai-maha me nga taonga puna pai.

Na reira, he mea whakamahia noawaro maitaii roto i te whānuitanga o nga tono miihini.

SAE1075 or CK75 kei roto 0.7-0.8% waro, 0.15-0.35% silicon, 0.6-0.9% manganese, me te 0.03% te ūkuikui me te whanariki. He te kaha o te 1230-1340 MPa, te kaha tuku o te 1130-1240 MPa, me te pakeke o te 57-63 HRC.

CK75 puna maitai he pai hardenability, te diameter hardenable tino i roto i te hinu taea tae 100 ~ 150mm.

He pai te CK75, te C75 ranei mo te hanga puna nui rawa atu, penei i nga puna rau rau i runga i nga bulldozers, nga puna porowhita nui me nga puna torsion nui ki runga kaipuke.

Ko te maitai o te puna CK75 he taonga maitai waro teitei. Ko tana hanganga matū ko te nuinga o te waro (C) i waenga i te 0.70-0.80%, te ihirangi silicon (Si) i waenga i te 0.10-0.35%, me te konupora (Mn) i waenga i te 0.60-0.80%.

I waenganui i te 0.90%, he iti iho i te 0.025% nga ihirangi o te ūkuikui (P) me te whanariki (S).

Ko te maitai o te puna CK75 he pai te elasticity me te uaua, a he maha nga wa e whakamahia ana ki te hanga i nga puna, nga matatahi, nga matatahi kite, nga maripi me etahi atu waahanga me nga taputapu e hiahia ana kia kaha te kaha me te whakakakahu i te aukati.

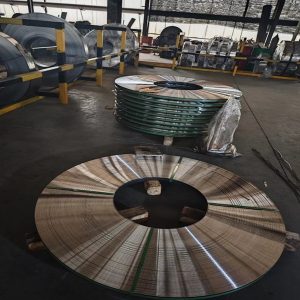

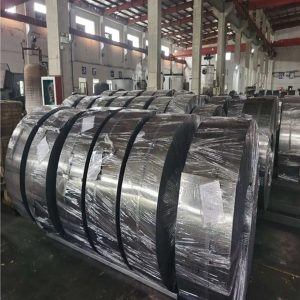

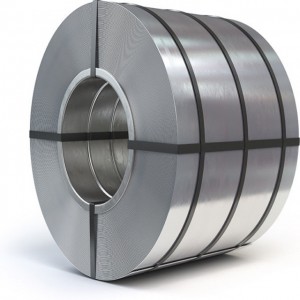

C75 C75s CK75 SAE 1075 puna tira maitai

1, Tikanga Tukunga:

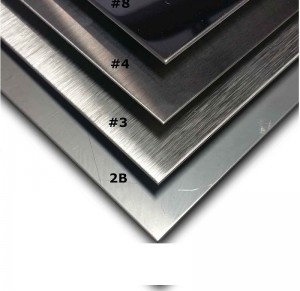

| Tikanga Tukunga | Rahi | Mata | Tapa |

| 1.Matao Ka Hurihia | 1.Matotoru: 0.09-8mm | He kanapa / Kōrohia / Kōrangi/Kōwhai | Wehenga |

| 2.Cold Rolled+Hydrogen Annealed | 2.Whanui: 6-450mm | Porowhita | |

| 3.Cold Rolled+hardened+Tempered | Roowhio roto diamita: 300-800mm | Tapawhā |

2, Tauritenga māka:

| TE WHAKATAERETANGA MO TE KOA | ||||||||

| HAINA GB/T | USA ASTM | HAAPANA JIS | TIERIA DIN | WANANGA NF | WANANGA BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | — | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL,SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3,Tito Matū:

| Paerewa | Kōeke | Tito matū(%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | V | ||

| GB/T699 | 45 | 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47~0.55 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52~0.60 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57~0.65 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62~0.70 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67~0.75 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72~0.80 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37~0.44 | 0.17~0.37 | 0.70~1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42~0.50 | 0.17~0.37 | 0.70~1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62~0.70 | 0.17~0.37 | 0.90~1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95~1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47~0.55 | 0.17~0.37 | 0.80~1.10 | 0.035 | 0.035 | 0.90~1.20 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 50CrVA | 0.47~0.54 | 0.17~0.37 | 0.50~0.80 | 0.025 | 0.025 | 0.80~1.10 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 75Cr1 | 0.7~0.8 | 0.25~0.5 | 0.50~0.70 | 0.035 | 0.035 | 0.30~0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52~0.60 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56~0.64 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |