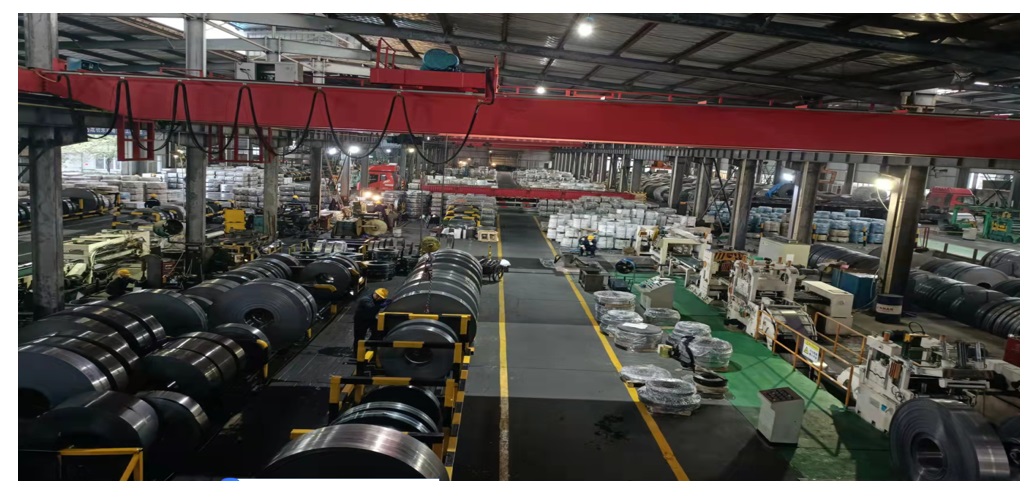

China EN10132 Standard SAE1075 ozizira adagulung'undisa mpweya zitsulo Mzere CK75 C75 C75S Spring zitsulo Mzere Wopanga ndi Wopereka | Ruyi

TS EN 10132 Standard SAE1075 Mzere wachitsulo wozizira wa carbonCK75C75Mzere wachitsulo wa C75S Spring ali ndi mpweya wa 0.7-0.8% womwe umaupanga kukhala zitsulo zamitundu yambiri za carbon zomwe zimakhala ndi masika abwino. Chifukwa chake, ndi chitsulo chomwe chimagwiritsidwa ntchito kwambiri pamakina osiyanasiyana aukadaulo.

SAE1075 kapenaCK75muli 0.7-0.8% carbon, 0.15-0.35% silikoni, 0.6-0.9% manganese, ndi 0.03% phosphorous ndi sulufule. Ili ndi mphamvu zolimba za 1230-1340 MPa, zokolola za 1130-1240 MPa, ndi kuuma kwa 57-63 HRC.

CK75 kasupe zitsulo ali hardability bwino, ndi awiri ovuta kuumitsa mu mafuta akhoza kufika 100 ~ 150mm. CK75 kapena C75 Ndi Yoyenera kupanga akasupe akulu kwambiri, monga akasupe a masamba owunjikana pa ma bulldozer, akasupe akulu a koyilo ndi akasupe akulu ophulitsira zombo.

CK75 masika zitsulo ndi mkulu-mpweya zitsulo zakuthupi. Kapangidwe kake ka mankhwala makamaka kumaphatikizapo carbon (C) zomwe zili pakati pa 0.70-0.80%, silicon (Si) zomwe zili pakati pa 0.10-0.35%, ndi manganese (Mn) zomwe zili pakati pa 0.60-0.80%. Pakati pa 0.90%, zomwe zili mu phosphorous (P) ndi sulfure (S) ndizochepera 0.025% motsatira. Chitsulo cha CK75 chakumapeto chimakhala ndi kukhuthala bwino komanso kulimba ndipo nthawi zambiri chimagwiritsidwa ntchito popanga akasupe, masamba, masamba, mipeni ndi mbali zina ndi zida zomwe zimafunikira mphamvu yayikulu komanso kukana kuvala.

C75 C75s CK75 SAE 1075 mzere wachitsulo wachitsulo

1, Zoyenera Kutumiza:

| Delivery Condition | Makulidwe | Pamwamba | M'mphepete |

| 1.Yozizira Yozungulira | 1.Kukula: 0.09-8mm | Wowala / Wopukutidwa / Blue/Yellow | Mpata |

| 2.Wozizira Wodzigudubuza+Hydrogen Annealed | 2.Ufupi: 6-450mm | Kuzungulira | |

| 3.Wozizira Wodzigudubuza+Wowumitsa+Wotentha | Coil mkati diameter: 300-800mm | Square |

2, Kufananiza Makalasi:

| MFUNDO KUYEREKEZANITSA KWA SPRING SITEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | GERMANY DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | Mtengo wa 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | - | SK85 | ||||||

| 40Mn | 1043 | Chithunzi cha SWRH42B | 40 mn4 | 40m5 ku | 080A40 | SL, SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | Chithunzi cha S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55 ndi7 | 55 ndi7 | 251H60 | 55Sicr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65 ndi7 | 65 ndi7 | 251H60 | 61Sicr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75kr1 | 75kr1 | 75kr1 | 75kr1 | |||||

| 51Crv4 | 5160 | SUP9A | 51Crv4 | 51Crv4 | Chithunzi cha SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | Chithunzi cha SPS9 | SUP13 | |||

| 50 CrVA | 6150 | SUP10 | 51Crv4 | 51Crv4 | 735A51 | 51Crv4 | Chithunzi cha SPS6 | SUP10 |

3, Chemical Mapangidwe:

| Standard | Gulu | Mapangidwe a Chemical (%) | ||||||||

| C | Si | Mn | P | S | Cr | Ndi | Ku | V | ||

| GB/T699 | 45 | 0.42 ~ 0.50 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47 ~ 0.55 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52 ~ 0.60 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57 ~ 0.65 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62-0.70 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67-0.75 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72 ~ 0.80 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | mn40 | 0.37-0.44 | 0.17-0.37 | 0.70 ~ 1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | mn45 | 0.42 ~ 0.50 | 0.17-0.37 | 0.70 ~ 1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | mn65 | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~ 0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95 ~ 1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51Crv4 | 0.47 ~ 0.55 | 0.17-0.37 | 0.80-1.10 | 0.035 | 0.035 | 0.90-1.20 | 0.3 | 0.3 | 0.10 ~ 0.20 |

| GB/T3077 | 50 CrVA | 0.47 ~ 0.54 | 0.17-0.37 | 0.50 ~ 0.80 | 0.025 | 0.025 | 0.80-1.10 | 0.3 | 0.3 | 0.10 ~ 0.20 |

| GB/T3077 | 75kr1 | 0.7 ~ 0.8 | 0.25 ~ 0.5 | 0.50 ~ 0.70 | 0.035 | 0.035 | 0.30-0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52 ~ 0.60 | 1.50 ~ 2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56 ~ 0.64 | 1.50 ~ 2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

4, Kulekerera Kwathu:

| KUNENERERA KWAKUNENERA | |||||||

| Kunenepa mwadzina (mm) | W <125 | 125 <= W | |||||

| A | B | C | A | B | C | ||

| 0,15~0,25 | TS EN | ± 0,015 | ± 0,012 | ± 0,008 | ± 0,020 | ± 0,015 | ± 0,010 |

| Mtengo wotsika kwambiri wa magawo a Metal STEEL | ± 0,008 | ± 0,010 | |||||

| 0,25~0,40 | TS EN | ± 0,020 | ± 0,015 | ± 0,010 | ± 0,025 | ± 0,020 | ± 0,012 |

| Mtengo wotsika kwambiri wa magawo a Metal STEEL | ± 0,010 | ± 0,012 | |||||

| 0,40~0,60 | TS EN | ± 0,025 | ± 0,020 | ± 0,012 | ± 0,030 | ± 0,025 | ± 0,015 |

| Mtengo wotsika kwambiri wa magawo a Metal STEEL | ± 0,015 | ± 0,015 | |||||

| 0,60-1,00 | TS EN | ± 0,030 | ± 0,025 | ± 0,015 | ± 0,035 | ± 0,030 | ± 0,020 |

| Mtengo wotsika kwambiri wa magawo a Metal STEEL | ± 0,015 | ± 0,020 | |||||

| 1,00-1,50 | TS EN | ± 0,035 | ± 0,030 | ± 0,020 | ± 0,040 | ± 0,035 | ± 0,025 |

| Mtengo wotsika kwambiri wa magawo a Metal STEEL | ± 0,020 | ± 0,025 | |||||

| 1,50-2,50 | TS EN | ± 0,040 | ± 0,035 | ± 0,025 | ± 0,050 | ± 0,040 | ± 0,030 |

| Mtengo wotsika kwambiri wa magawo a Metal STEEL | ± 0,025 | ± 0,030 | |||||

| 2,50-4,00 | TS EN | ± 0,050 | ± 0,040 | ± 0,030 | ± 0,060 | ± 0,050 | ± 0,035 |

| Mtengo wotsika kwambiri wa magawo a Metal STEEL | ± 0,030 | ± 0,035 | |||||

| Chonde titumizireni ngati muli ndi zofunikira zapadera. | |||||||

| WIDTH TOLERANCES FOR SLIT EDGE (GK) | |||||||

| Width Tolerances TS EN 10140 | Kukula (mm) | ||||||

| Kunenepa mwadzina (mm) | W <125 | 125 <= W <= 250 | 250 | ||||

| A | B | A | B | A | B | ||

| 0,2 ~ 0,6 | TS EN | ± 0,15 | ± 0,10 | ± 0,20 | ± 0,13 | ± 0,25 | ± 0,18 |

| Mtengo wapatali wa magawo TOP METAL zitsulo | ± 0,10 | ± 0,13 | ± 0,18 | ||||

| 0,6-1,5 | TS EN | ± 0,20 | ± 0,13 | ± 0,25 | ± 0,18 | ± 0,30 | ± 0,20 |

| Mtengo wapatali wa magawo TOP METAL zitsulo | ± 0,13 | ± 0,18 | ± 0,20 | ||||

| 1, 5 ~ 2, 5 | TS EN | ± 0,25 | ± 0,18 | ± 0,30 | ± 0,20 | ± 0,35 | ± 0,25 |

| Mtengo wapatali wa magawo TOP METAL zitsulo | ± 0,18 | ± 0,20 | ± 0,25 | ||||

| 2,5 ~ 4,0 | TS EN | ± 0,30 | ± 0,20 | ± 0,35 | ± 0,25 | ± 0,40 | ± 0,30 |

| Mtengo wapatali wa magawo TOP METAL zitsulo | ± 0,20 | ± 0,25 | ± 0,30 | ||||

5, Mapulogalamu:

| Mankhwala muyezo | Mapulogalamu | S50C(CK50/1050) | - Tepi yoyezera | |

| 65Si2Mn | - Springs | - Zigawo zamakamera zamakina | ||

| 50CrV4 | - Springs | - Zigawo za unyolo | ||

| 51Crv4 | - Springs | - Springs | ||

| SK4 (1095) | - Tepi yoyezera | - Zigawo za Clutch | ||

| - Zida zopangira | - Ma washers | |||

| - Zolembera zolembera | - Zomangamanga zachitetezo | |||

| - Zida zopangira mphepo | S55C(CK55/1050) | - Springs | ||

| - Springs | - Nsapato zachitetezo | |||

| - Zodula | - Otsegula amatha | |||

| - Kuluka singano | - Thompson masamba | |||

| SK5 (1085) | - Tepi yoyezera | - Zigawo zamakamera zamakina | ||

| - Magazi | S60C(CK60/1060) | - Zigawo za unyolo | ||

| - Springs | - Macheka am'manja opangira matabwa | |||

| - Zodula | - Nsapato zachitetezo | |||

| - Kuluka singano | - Springs | |||

| - Macheka opangira matabwa | - Zigawo za zida zaofesi | |||

| ndi kukumba | - Ma washers | |||

| - Macheka ozungulira | S65C(65MN/CK67) | - Nsapato zachitetezo | ||

| - Zigawo za zida zaofesi | - Zigawo za Clutch | |||

| S45C(CK45/1045) | - Zigawo za Clutch | - Springs | ||

| - Zigawo za unyolo | - Ma washers | |||

| - Osunga | S75C(CK75/1075) | - Zigawo za Clutch | ||

| - Ma washers | - Springs | |||

| S50C(CK50/1050) | - Tepi yoyezera | - Masamba a band | ||

| - Zigawo zamakamera zamakina |