China Ck75 Steel C75s C75 SAE 1075 spring steel strip

CK75 simbi isimbi yakakwira-kabhoni, ine C ichiratidza kabhoni inosvika 0.75%. Mamwe makuru alloying zvinhu anosanganisira manganese, silicon, phosphorus, nezvimwe.

Iyo CK75 Steel ine zvinotevera zvivakwa uye mashandisirwo:

Hunhu hweCK75 Simbi:

Iine goho repamusoro simba uye kusimba uye inokwanisa kumira mitoro mikuru.

Iine maitiro akanaka emagetsi uye maitiro ekurapa kupisa, uye akakodzera kugadzira zvitubu zvinoda simba rakakwirira uye kupfeka kusagadzikana.

Kuomarara kwayo kunogona kugadziriswa kuburikidza nekupisa kurapwa kuzadzisa zvinodiwa zvemhando dzakasiyana dzekushandisa.

Iyo ine imwe magineti permeability uye inogona kushandiswa kugadzira electromagnetic zvikamu.

Iyo ine yakanaka corrosion resistance uye inogona kuchengetedza yakanaka kupera kwepamusoro uye kuramba kwemamiriro ekunze pasi pemamwe mamiriro.

Kushandiswa kweCK75 Steel:

Indasitiri yemotokari: inoshandiswa kugadzira mota chassis zvitubu uye kumiswa system zvikamu.

Kugadzira michina: inoshandiswa kugadzira zvitubu zvakasiyana-siyana zvemuchina, mekiniki zvikamu uye maturusi.

Masimba emagetsi nemagetsi: anoshandiswa kugadzira electromagnetic zvikamu uye conductive zvitubu.

Kuvaka uye fenicha: inoshandiswa kugadzira gonhi uye hwindo Hardware accessories uye zvitubu zvefenicha, nezvimwe.

Inokodzera kugadzira zvitubu zvakakura kwazvo, sezvitubu zvemashizha akarongedzerwa pamabulldozer, zvitubu zvakakura zvemakoiri uye zvitubu zvakakura zvekurovera pangarava.

CK75 Simbi yakaenzana neAISI 1075 carbon steelzvinosanganisira:

ASTM A29 (1075)

ASTM A510 (1075)

ASTM A713 (1075)

SAE J403 (1075)

SAE J412 (1075)

EN10132 Yakajairwa SAE1075 inotonhora yakakungurutswa kabhoni simbi strip CK75 C75 C75S Chitubu chesimbi tambo ine carbon content ye 0.7-0.8% ichiita kuti ive yakawanda-purpose carbon steel ine yakanaka spring properties.

Nokudaro, inowanzoshandiswacarbon steelmune dzakasiyana siyana dzeinjiniya application.

SAE1075 kana CK75 ine 0.7-0.8% kabhoni, 0.15-0.35% silicon, 0.6-0.9% manganese, uye 0.03% phosphorus nesarufa. Iyo ine simba rekusimba re1230-1340 MPa, goho simba re1130-1240 MPa, uye kuoma kwe57-63 HRC.

CK75 chitubu simbi ine nani kuomarara, yakakosha kuomarara dhayamita muoiri inogona kusvika 100 ~ 150mm.

CK75 kana C75 Inokodzera kugadzira zvitubu zvakakura kwazvo, sezvitubu zvemashizha akaturikidzana pamabulldozer, zvitubu zvakakura zvemakoiri uye zvitubu zvakakura zve torsion pazvikepe.

CK75 chitubu simbi ndeyepamusoro-kabhoni simbi zvinhu. Mushonga wayo wemakemikari unonyanya kusanganisira kabhoni (C) zviri pakati pe0.70-0.80%, silicon (Si) zviri pakati pe0.10-0.35%, uye manganese (Mn) zviri pakati pe0.60-0.80%.

Pakati pe0.90%, zviri mukati me phosphorus (P) nesarufa (S) zvishoma pane 0.025% maererano.

CK75 chitubu simbi ine elasticity yakanaka uye kusimba uye inowanzoshandiswa kugadzira zvitubu, mashizha, masaha, mapanga uye zvimwe zvikamu uye maturusi anoda kusimba kwepamusoro uye kusapfeka.

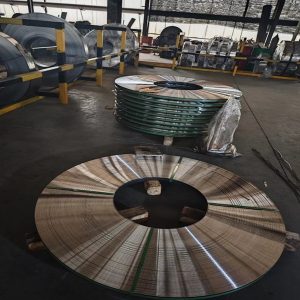

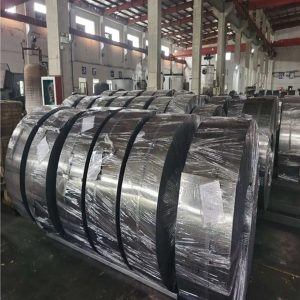

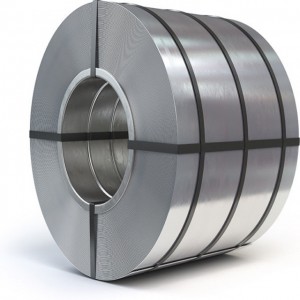

C75 C75s CK75 SAE 1075 chitubu simbi strip

1, Delivery Conditions:

| Delivery Condition | Saizi | Surface | Edge |

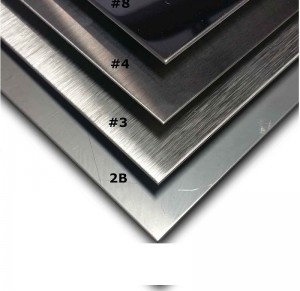

| 1.Kutonhora | 1.Kukora: 0.09-8mm | Bright / Polished / Blue/Yellow | Slit |

| 2.Cold Rolled+Hydrogen Annealed | 2.Kufara: 6-450mm | Round | |

| 3.Kutonhora Yakakungurutswa+Yakaoma+Yakaoma | Coil insider diameter: 300-800mm | Square |

2, Magiredhi kuenzanisa:

| MAGREDE EKUFANISWA ZVE SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | GERMANY DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | - | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL,SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3,Kuumbwa Kwemakemikari:

| Standard | Giredhi | Kuumbwa Kwemakemikari (%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | V | ||

| GB/T699 | 45 | 0.42 ~ 0.50 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47~0.55 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52 ~ 0.60 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57~0.65 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62 ~ 0.70 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67 ~ 0.75 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72 ~ 0.80 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37 ~ 0.44 | 0.17 ~ 0.37 | 0.70 ~ 1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42 ~ 0.50 | 0.17 ~ 0.37 | 0.70 ~ 1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62 ~ 0.70 | 0.17 ~ 0.37 | 0.90 ~ 1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95~1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47~0.55 | 0.17 ~ 0.37 | 0.80~1.10 | 0.035 | 0.035 | 0.90 ~ 1.20 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 50CrVA | 0.47 ~ 0.54 | 0.17 ~ 0.37 | 0.50~0.80 | 0.025 | 0.025 | 0.80~1.10 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 75Cr1 | 0.7~0.8 | 0.25~0.5 | 0.50~0.70 | 0.035 | 0.035 | 0.30 ~ 0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52 ~ 0.60 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56~0.64 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |