China DC51D ZF Galvanized simbi ndiro Coil Manufacturer uye Supplier | Ruiyi

Kupisa dip galvanized simbi ndiro DC51D, inonziwo seinopisa dip galvanized steel sheetDC51D+Z uye inopisa dip zingi yakavharwa simbi ndiro uye coil DC51D+ZF.Pasi peQ/BQB 420 simbi yakajairwa, pane DC51D+Z,DC51D+ZF inova yekubhenda nekuforofa mhando,DC52D+Z,DC52+ZF inova yemhando yekudhirowa,DC53+Z,DC53+ZF inova yekudhirowa kwakadzika mhando,DC54D+Z,DC54D+ZF inova yemhando yakadzika yekudhirowa,DC56D+Z,DC56D+ZF inova yekuwedzera kudhirowa kwakadzika.

DX51D inomirira galvanized steel sheet. D yekutanga inoreva simbi yakatsetseka yekugadzira inotonhora. Iyo X inoreva kuti kutenderera mamiriro haaperi. 51 ndiyo nhamba yakatevedzana yesimbi. Yechipiri D inoreva kupisa kwakanyikwa marata.

Kana iyo X ikava C, inova DC51D, zvinoreva kuti substrate rolling state iri kutonhora. Nepo DD51D zvichireva kuti kutenderedza mamiriro eiyo substrate inopisa kukunguruka.

Uyezve, zviri nyore kuona DX51D-Z, DX51D-ZF kana DX51D-AZ. Iyo Z inoreva kuti galvanized coating iZinc. ZF zvinoreva kuti galvanized coating iZn-Fe alloy. AZ zvinoreva kuti galvanized coating is galvalume.

DX51D galvanized coils inogadzirwa zvinoenderana neEN 10346. Ukobvu hwezinc coating hunosiyana zvichienderana nezvinodiwa nevatengi.

DX51Dgalvanized coilsanoshandiswa zvakanyanya pakugadzira zvivakwa zvesimbi, matenga, mafirita profiles, drainage uye ventilation masisitimu, zvipingamupinyi zvemigwagwa, mabhiriji, uye midziyo yemumba (makesi uye zvikamu zvemukati).

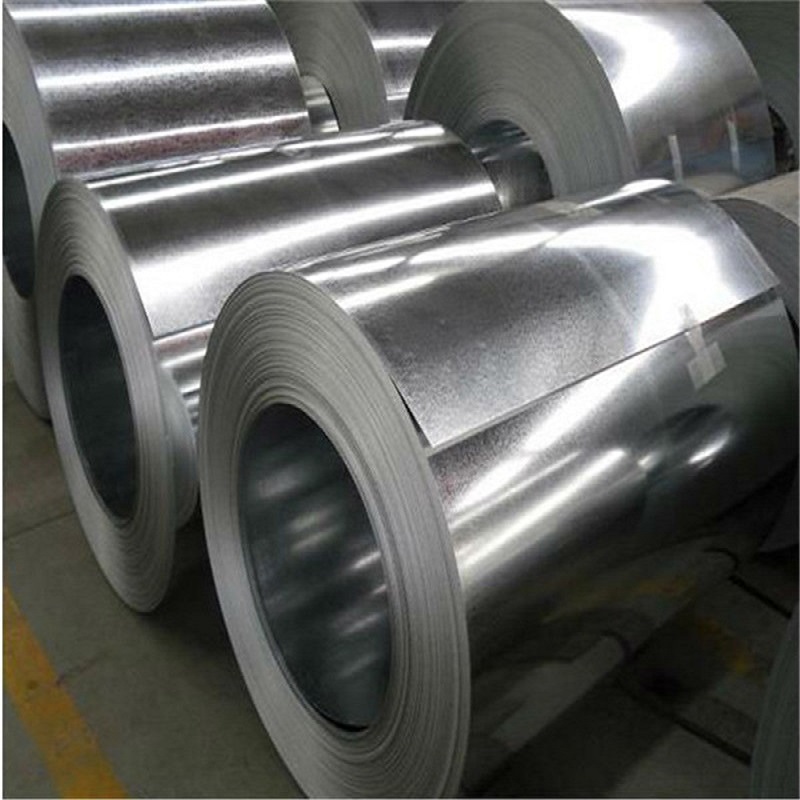

Zvigadzirwa zvesimbi zveDX51D zvinogadzirwa mumakoiri 0.4-1.6 mm gobvu uye 950-1250 mm yakafara. Iyo dhayamita yemukati yekoiri i600±20 mm uye dhayamita rekunze rinosvika 1300 mm. Huremu hwecoil hunosvika matani masere. Coils anopiwa neakachekwa edges (mill edges inogonekawo).

Kemikari kuumbwa uye michina zvivakwa zvinoenderana ne EN 10346

Cherechedza. Kushivirira kwehukuru uye maumbirwo kwakatsanangurwa mu EN 10143 (kushivirira kwehupamhi ndeyemakoiri mashoma e0.7 mm mukobvu)

Cherechedza. Zvinodiwa zvekugadzira uye weldability yezvakapedzwa zvigadzirwa zvinofanirwa kutariswa kana uchiraira huremu hwe zinc coating.

Zvishandiso uye maficha anopiwa setafura inotevera

| Steel Giredhi | Application | Feature |

|---|---|---|

| DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | Chinangwa chekutengeserana | Yakaderera kabhoni uye/kana Ultra-yakaderera kabhoni simbi |

| DC52D+Z (St04Z), DC52D+ZF | Kudhirowa | |

| DC53D+Z (St05Z), DC53D+ZF | Kudhirowa kwakadzika | Ultra-yakaderera kabhoni simbi |

| DC54D+Z (St06Z), DC54D+ZF | Kuwedzera kwakadzika kudhirowa | |

| DD54D+Z (St06ZR) | ||

| DC56D+Z (St07Z), DC56D+ZF | Supreme yakawedzera kudhirowa kwakadzika |

Kuumbwa Kwemakemikari%:

| bse simbi mhando | Giredhi | CHEMICAL COMPOSITION % | |||

|---|---|---|---|---|---|

| C | Si | Mn | P | ||

| simbi inotonhora yakakungurutswa | DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | ≤0.10 | - | ≤0.50 | ≤0.035 |

| DC52D+Z (St04Z), DC52D+ZF | ≤0.08 | - | ≤0.45 | ≤0.030 | |

| DC53D+Z (St05Z), DC53D+ZF | ≤0.08 | - | ≤0.40 | ≤0.030 | |

| DC54D+Z (St06Z), DC54D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| DC56D+Z (St07Z), DC56D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| simbi inopisa yakakungurutswa | DD51D+Z (St01ZR, St02ZR) | ≤0.10 | - | ≤0.50 | ≤0.035 |

| DD54D+Z (St06ZR) | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| Mechanical performances uye coating adhesiveness | |||||||

|---|---|---|---|---|---|---|---|

| Giredhi | Mechanical performances | Coating Adhesiveness | |||||

| Goho Simba MP | Tensile Simba MP ≥ | After Breakage Percent Elongation (LO=80mm,b=20mm)% ≥ | Bending Center Diameter muKutevera Coating Weight (g/m2)c (a=plate ukobvu) | ||||

| L0=80mm,b=20mm | |||||||

| Pasi pekutevera mazita ukobvu mm | ≤140/140 | >140/140~175/175 | >175/175 | ||||

| ≤0.7 | >0.7 | ||||||

| DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | - | 270~500 | 20 | 22 | 0a | 1a | 2a |

| DC52D+Z (St04Z), DC52D+ZF | 140~300 | 270~420 | 24 | 26 | |||

| DC53D+Z (St05Z), DC53D+ZF | 140~260 | 270~380 | 28 | 30 | |||

| DC54D+Z (St06Z) | 140~220 | 270~350 | 34 | 36 | |||

| DC54D+ZF | 32 | 34 | |||||

| DC56D+Z (St07Z) | 120~180 | 270~350 | 38 | 40 | |||

| DC56D+ZF | 36 | 38 | |||||

| Surface structure | Kodhi Nha. | Features | Application |

|---|---|---|---|

| Conventional spangle | Z | Spangles akakoniwa pane zinc coating pasi pemamiriro akajairwa mushure mekuputika. | Zvinangwa zvekutengesa |

| Small spangle | X | Pamusoro mumaspangles madiki pane akajairwa uye nekuda kwekudzorwa kudzoreredzwa kwe zinc coating. | Zvishandiso uko zvakajairwa spangles hazvigone kusangana nepamusoro pezvinodiwa. |

| Ganda rakapfuura spangle | G | Chimiro chepamusoro mushure mekurapa kwakakosha kweganda. | Zvishandiso zvemhando yepamusoro zvinodiwa, senge color coating base mahwendefa. |

| Ganda rakapfuura diki spangle | GX | ||

| Zero spangle | N | Hapana anooneka spangles pane coating pamusoro semhedzisiro yakakosha yekugadzira maitiro. | - |

| Zn-Fe alloy | R | Hapana spangle, grey, kazhinji matte | Inoshanda pakuwedzera pendi |

| Kurapa kwepamusoro | |

|---|---|

| Chromate treatment (L) | Chromate kurapwa kurapwa kwemakemikari nechinangwa chekudzivirira ngura chena inoumbwa pane zvigadzirwa panguva yekufambisa uye kuchengetedza. |

| Kuzora mafuta (Y) | Oiri ndeyekudzivirira ngura chena inoumbwa pane zvigadzirwa panguva yekufambisa uye kuchengetedza. |

| Chromate kurapwa+ Oiling (LY) | Chromate treatment+ Oiling (LY) Uku kurapwa nemafuta mushure mekurapa kwechromate kwepamusoro ndekwekuenderera mberi kudzivirira kuumbwa kwemavara machena. |

Surface quality

| Kodhi Nhamba. | Features |

|---|---|

| FB (O3) | t inotenderwa kuvepo kwemavara madiki ekukukurwa, mavara matema, mavanga ezvimedu, zvirema zvidiki zvechromate kurapwa uye zvidiki zinc particles. |

| FC (O4) | Hapana nzvimbo yekukukurwa inobvumidzwa. Nekudaro, zvinotenderwa kuvepo kwechiedza chechiedza, zvikweshwa, zinc kuyerera ripple mamaki, madiki chromate kurapwa akaremara mudiki, nepo rimwe divi richifanira kusvika paFB zvinodiwa zvishoma. |

| FD (O5) | Rumwe rutivi rwemhando yakanaka runofanira kuwedzera kudzora pane hurema, kureva kunaka kwechimiro mushure mekupenda kusakanganiswa, uye rimwe divi rinofanirwa kusvika paFB zvinoda zvishoma. |

Simbi giredhi referenzi runyorwa rwezviyero, iwo akataurwa zviyero uye mamwe mazinga

| Q/BQB 420-2003 | EN10142:2000 EN10147:2000 EN10292:2000 | EN 10142:1990 EN 10147:1991 | JISG3302-1994 | ASTMA653M-2002 |

|---|---|---|---|---|

| DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | DC51D+Z, +ZF | FeP02GZ, ZF | SGCC | CS mhando C |

| DC52D+Z (St04Z), DC52D+ZF | DC52D+Z, +ZF | FeP03GZ, ZF | SGCC | CS mhando A, mhando B |

| DC53D+Z (St05Z), DC53D+ZF | DC53D+Z, +ZF | FeP05GZ, ZF | SGCD1 | FS mhando A, mhando B |

| DC54D+Z (St06Z), DC54D+ZF | DC54D+Z, +ZF | FeP06GZ, ZF | SGCD2 | DDS |

| DC56D+Z (St07Z), DC56D+ZF | DC56D+Z, +ZF | DX56D+Z, +ZF (SEW 021) | SGCD3 | EDDS |

| Q/BQB 420 Kupisa-kunyudza kwakakurudzira/zingi-iron alloy/zingi-magnesium alloy yakavharwa simbi pepa uye tambo | ||||

| Zita resimbi | Kupisa dip galvanized / kutonhora yakakungurutswa substrate | Kupisa dip galvanized / inopisa yakakungurutswa substrate | Zinc iron alloy | Zinc magnesium alloy |

| Simbi yakapfava kana interstitial-isina simbi | DC51D+Z | DD51D+Z | DC51D+ZF | DC51D+ZM |

| DC52D+Z | DC52D+ZF | DC52D+ZM | ||

| DC53D+Z | DC53D+ZF | DC53D+ZM | ||

| DC54D+Z | DC54D+ZF | DC54D+ZM | ||

| DC56D+Z | DC56D+ZF | DC56D+ZM | ||

| DC57D+Z | DC57D+ZF | DC57D+ZM | ||

| Carbon structural simbi kana yakaderera alloy simbi | S220GD+Z | S220GD+ZF | S220GD+ZM | |

| S250GD+Z | S250GD+ZF | S250GD+ZM | ||

| S280GD+Z | S280GD+ZF | S280GD+ZM | ||

| S320GD+Z | S320GD+ZF | S320GD+ZM | ||

| S350GD+Z | S350GD+ZF | S350GD+ZM | ||

| S550GD+Z | S550GD+ZM | |||

| Interstitial-isina high-simba simbi | HC180YD+Z | HC180YD+ZF | HC180YD+ZM | |

| HC220YD+Z | HC220YD+ZF | HC220YD+ZM | ||

| B240P1D+Z | B240P1D+ZF | B240P1D+ZM | ||

| B260LYD+Z | B260LYD+ZF | B260LYD+ZM | ||

| HC260YD+Z | HC260YD+ZF | HC260YD+ZM | ||

| bika simbi yakaoma | HC180BD+Z | HC180BD+ZF | HC180BD+ZM | |

| HC220BD+Z | HC220BD+ZF | HC220BD+ZM | ||

| HC260BD+Z | HC260BD+ZF | HC260BD+ZM | ||

| HC300BD+Z | HC300BD+ZF | HC300BD+ZM | ||

| low alloy high simba simbi | HC260LAD+Z | HC260LAD+ZF | HC260LAD+ZM | |

| HC300LAD+Z | HC300LAD+ZF | HC300LAD+ZM | ||

| HC340LAD+Z | HD340LAD+Z | HC340LAD+ZF | HC340LAD+ZM | |

| HC380LAD+Z | HC380LAD+ZF | HC380LAD+ZM | ||

| HC420LAD+Z | HD410LAD+Z | HC420LAD+ZF | HC420LAD+ZM | |

| HC460LAD+Z | HC460LAD+ZF | HC460LAD+ZM | ||

| HC500LAD+Z | HC500LAD+ZF | HC500LAD+ZM | ||

| HD550LAD+Z | ||||

| Duplex simbi | HC250/450DPD+Z | HC250/450DPD+ZF | HC250/450DPD+ZM | |

| HC300/500DPD+Z | HC300/500DPD+ZF | HC300/500DPD+ZM | ||

| HC280/590DPD+Z | HC280/590DPD+ZF | HC280/590DPD+ZM | ||

| HC340/590DPD+Z | HC340/590DPD+ZF | HC340/590DPD+ZM | ||

| B340/590DPD+Z | B340/590DPD+ZF | B340/590DPD+ZM | ||

| HC420/780DPD+Z | HC420/780DPD+ZF | |||

| HC500/780DPD+Z | HC500/780DPD+ZF | |||

| HC550/980DPD+Z | HC550/980DPD+ZF | |||

| HC650/980DPD+Z | HC650/980DPD+ZF | |||

| HC700/980DPD+Z | HC700/980DPD+ZF | |||

| HC740/1180DPD+Z | HC740/1180DPD+ZF | |||

| HC820/1180DPD+Z | HC820/1180DPD+ZF | |||

| shanduko yakakonzera plasticity simbi | HC380/590TRD+Z | HC380/590TRD+ZF | ||

| HC400/690TRD+Z | HC400/690TRD+ZF | |||

| HC420/780TRD+Z | HC420/780TRD+ZF | |||

| Complex phase simbi | HC570/780CPD+Z | HD660/760CPD+Z | ||

| HC780/980CPD+Z | ||||

| yakaoma ductile simbi | HC600/980QPD+Z | |||

| HC600/980QP-ELD+Z | ||||

| HC820/1180QPD+Z | ||||

| HC820/1180QP-ELD+Z | ||||