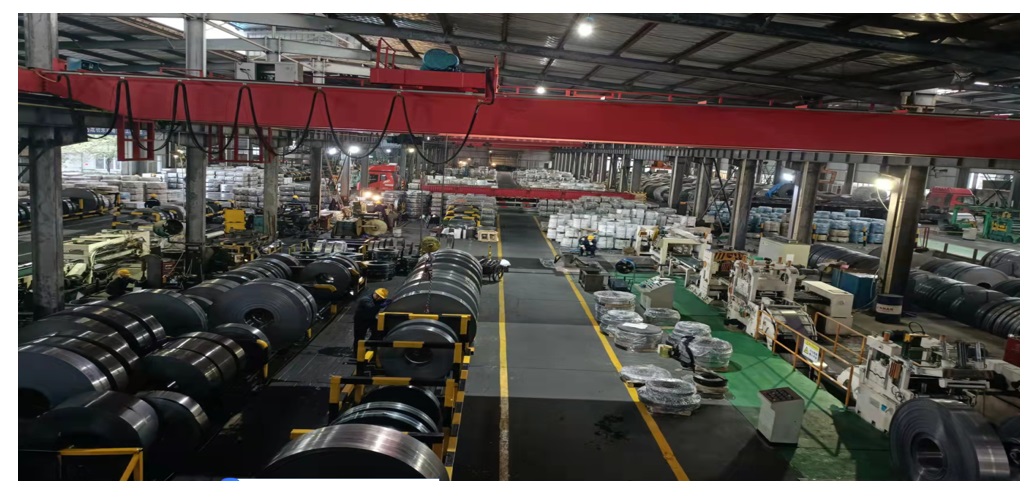

China EN10132 Standard SAE1075 inotonhora yakakungurutswa kabhoni simbi strip CK75 C75 C75S Chitubu simbi strip Mugadziri uye Supplier | Ruiyi

EN10132 Yakajairwa SAE1075 inotonhora yakakungurutswa kabhoni simbi stripCK75C75C75S Chitubu chesimbi tambo ine carbon content ye 0.7-0.8% ichiita kuti ive yakawanda-purpose carbon steel ine yakanaka spring properties. Naizvozvo, inowanzoshandiswa kabhoni simbi mune dzakasiyana siyana dzeinjiniya application.

SAE1075 kanaCK75ine 0.7-0.8% kabhoni, 0.15-0.35% nesilicon, 0.6-0.9% manganese, uye 0.03% phosphorus nesarufa. Iyo ine simba rekusimba re1230-1340 MPa, goho simba re1130-1240 MPa, uye kuoma kwe57-63 HRC.

CK75 chitubu simbi ine nani kuomarara, yakakosha kuomarara dhayamita muoiri inogona kusvika 100 ~ 150mm. CK75 kana C75 Inokodzera kugadzira zvitubu zvakakura kwazvo, sezvitubu zvemashizha akaturikidzana pamabulldozer, zvitubu zvakakura zvemakoiri uye zvitubu zvakakura zve torsion pazvikepe.

CK75 chitubu simbi ndeyepamusoro-kabhoni simbi zvinhu. Mushonga wayo wemakemikari unonyanya kusanganisira kabhoni (C) zviri pakati pe0.70-0.80%, silicon (Si) zviri pakati pe0.10-0.35%, uye manganese (Mn) zviri pakati pe0.60-0.80%. Pakati pe0.90%, zviri mukati me phosphorus (P) nesarufa (S) zvishoma pane 0.025% maererano. CK75 chitubu simbi ine elasticity yakanaka uye kusimba uye inowanzoshandiswa kugadzira zvitubu, mashizha, masaha, mapanga uye zvimwe zvikamu uye maturusi anoda kusimba kwepamusoro uye kusapfeka.

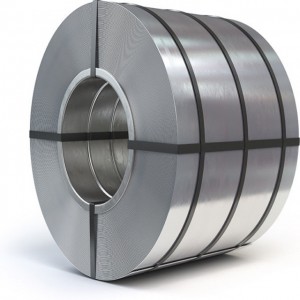

C75 C75s CK75 SAE 1075 chitubu simbi strip

1, Delivery Conditions:

| Delivery Condition | Saizi | Surface | Edge |

| 1.Kutonhora | 1.Kukora: 0.09-8mm | Bright / Polished / Blue/Yellow | Slit |

| 2.Cold Rolled+Hydrogen Annealed | 2.Kufara: 6-450mm | Round | |

| 3.Kutonhora Yakakungurutswa+Yakaoma+Yakaoma | Coil insider diameter: 300-800mm | Square |

2, Magiredhi kuenzanisa:

| MAGREDE EKUFANISWA ZVE SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | GERMANY DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | - | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL,SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3,Kuumbwa Kwemakemikari:

| Standard | Giredhi | Kuumbwa Kwemakemikari (%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | V | ||

| GB/T699 | 45 | 0.42 ~ 0.50 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47~0.55 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52 ~ 0.60 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57~0.65 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62 ~ 0.70 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67 ~ 0.75 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72 ~ 0.80 | 0.17 ~ 0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37 ~ 0.44 | 0.17 ~ 0.37 | 0.70 ~ 1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42 ~ 0.50 | 0.17 ~ 0.37 | 0.70 ~ 1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62 ~ 0.70 | 0.17 ~ 0.37 | 0.90 ~ 1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95~1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47~0.55 | 0.17 ~ 0.37 | 0.80~1.10 | 0.035 | 0.035 | 0.90 ~ 1.20 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 50CrVA | 0.47 ~ 0.54 | 0.17 ~ 0.37 | 0.50~0.80 | 0.025 | 0.025 | 0.80~1.10 | 0.3 | 0.3 | 0.10~0.20 |

| GB/T3077 | 75Cr1 | 0.7~0.8 | 0.25~0.5 | 0.50~0.70 | 0.035 | 0.035 | 0.30 ~ 0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52 ~ 0.60 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56~0.64 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

4, Kushivirira Kwedu:

| KUTAMBIRA KUKORA | |||||||

| Ukobvu hwezita (mm) | W <125 | 125 <= W | |||||

| A | B | C | A | B | C | ||

| 0,15~0,25 | TS EN | ±0,015 | ±0,012 | ±0,008 | ±0,020 | ±0,015 | ±0,010 |

| Pamusoro pesimbi STEEL | ±0,008 | ±0,010 | |||||

| 0,25~0,40 | TS EN | ±0,020 | ±0,015 | ±0,010 | ±0,025 | ±0,020 | ±0,012 |

| Pamusoro pesimbi STEEL | ±0,010 | ±0,012 | |||||

| 0,40~0,60 | TS EN | ±0,025 | ±0,020 | ±0,012 | ±0,030 | ±0,025 | ±0,015 |

| Pamusoro pesimbi STEEL | ±0,015 | ±0,015 | |||||

| 0,60~1,00 | TS EN | ±0,030 | ±0,025 | ±0,015 | ±0,035 | ±0,030 | ±0,020 |

| Pamusoro pesimbi STEEL | ±0,015 | ±0,020 | |||||

| 1,00~1,50 | TS EN | ±0,035 | ±0,030 | ±0,020 | ±0,040 | ±0,035 | ±0,025 |

| Pamusoro pesimbi STEEL | ±0,020 | ± 0,025 | |||||

| 1,50~2,50 | TS EN | ±0,040 | ±0,035 | ±0,025 | ±0,050 | ±0,040 | ±0,030 |

| Pamusoro pesimbi STEEL | ±0,025 | ±0,030 | |||||

| 2,50~4,00 | TS EN | ±0,050 | ±0,040 | ±0,030 | ±0,060 | ±0,050 | ±0,035 |

| Pamusoro pesimbi STEEL | ±0,030 | ±0,035 | |||||

| Ndapota taura nesu kana iwe uine chero zvakakosha zvinodiwa. | |||||||

| WIDTH TOLERANCES FOR SLIT EDGE (GK) | |||||||

| Width Tolerances TS EN 10140 | Kukura Kwekugadzira (mm) | ||||||

| Ukobvu hwezita (mm) | W <125 | 125 <= W <= 250 | 250 | ||||

| A | B | A | B | A | B | ||

| 0,2 ~ 0,6 | TS EN | ± 0,15 | ± 0,10 | ± 0,20 | ± 0,13 | ± 0,25 | ± 0,18 |

| TOP METAL STEEL | ± 0,10 | ± 0,13 | ± 0,18 | ||||

| 0,6 ~ 1,5 | TS EN | ± 0,20 | ± 0,13 | ± 0,25 | ± 0,18 | ± 0,30 | ± 0,20 |

| TOP METAL STEEL | ± 0,13 | ± 0,18 | ± 0,20 | ||||

| 1,5 ~ 2,5 | TS EN | ± 0,25 | ± 0,18 | ± 0,30 | ± 0,20 | ± 0,35 | ± 0,25 |

| TOP METAL STEEL | ± 0,18 | ± 0,20 | ± 0,25 | ||||

| 2,5 ~ 4,0 | TS EN | ± 0,30 | ± 0,20 | ± 0,35 | ± 0,25 | ± 0,40 | ± 0,30 |

| TOP METAL STEEL | ± 0,20 | ± 0,25 | ± 0,30 | ||||

5, Zvishandiso:

| Product standard | Applications | S50C(CK50/1050) | – Tepi yekuyeresa | |

| 65Si2Mn | – Zvitubu | - Zvimiro zvikamu zvekamera | ||

| 50CrV4 | – Zvitubu | – Cheni zvikamu | ||

| 51CrV4 | – Zvitubu | – Zvitubu | ||

| SK4 (1095) | – Tepi yekuyeresa | - Clutch zvikamu | ||

| – Razor blades | – Mawachi | |||

| – Pen points | – Kuchengetedza mabhakisi | |||

| - Zvitubu zvemhepo | S55C(CK55/1050) | – Zvitubu | ||

| – Zvitubu | – Safety shangu | |||

| – Cutlery | – Anogona kuvhura | |||

| – Kuruka tsono | – Thompson mashizha | |||

| SK5 (1085) | – Tepi yekuyeresa | - Zvimiro zvikamu zvekamera | ||

| – Zviyero | S60C(CK60/1060) | – Cheni zvikamu | ||

| – Zvitubu | – Masaha emaoko ekugadzira huni | |||

| – Cutlery | – Safety shangu | |||

| – Kuruka tsono | – Zvitubu | |||

| – Band masaha ehuni | - Zvikamu zvemuhofisi | |||

| uye kugadzira mapuranga | – Mawachi | |||

| – Round saw | S65C(65MN/CK67) | – Safety shangu | ||

| - Zvikamu zvemuhofisi | - Clutch zvikamu | |||

| S45C(CK45/1045) | - Clutch zvikamu | – Zvitubu | ||

| – Cheni zvikamu | – Mawachi | |||

| – Vanochengeta | S75C(CK75/1075) | - Clutch zvikamu | ||

| – Mawachi | – Zvitubu | |||

| S50C(CK50/1050) | – Tepi yekuyeresa | – Band masaha | ||

| - Zvimiro zvikamu zvekamera |