China Ck75 Steel C75s C75 SAE 1075 strip birta guga

CK75 steel waa walxo bir kaarboon ah oo aad u sareysa, iyadoo C ay muujineyso ka kooban kaarboon dhan 0.75%. Qaybaha kale ee ugu muhiimsan waxaa ka mid ah manganese, silicon, fosfooraska, iwm.

Birta CK75 waxay leedahay sifooyinka iyo codsiyada soo socda:

Sifada CK75 Birta:

Waxay leedahay xoog wax-soo-saar sare iyo xoog adkaysi waxayna u adkeysan kartaa culeysyada xajinta ee waaweyn.

Waxay leedahay sifooyin farsamo oo wanaagsan iyo guryaha daaweynta kulaylka, waxayna ku habboon tahay ilaha wax soo saarka ee u baahan xoog sare iyo xirashada caabbinta.

Adaggeeda waxaa lagu hagaajin karaa daaweynta kulaylka si loo daboolo baahiyaha xaaladaha kala duwan ee codsiga.

Waxay leedahay birlab birlab ah oo gaar ah waxaana loo isticmaali karaa in lagu soo saaro qaybaha korantada.

Waxay leedahay iska caabbinta daxalka wanaagsan waxayna ilaalin kartaa dhamaystirka dusha sare iyo iska caabinta cimilada xaaladaha qaarkood.

Codsiga birta CK75:

Warshadaha baabuurta: waxaa loo isticmaalaa in lagu soo saaro ilaha chassis baabuurta iyo qaybaha nidaamka joojinta.

Soo saarista mishiinada: waxaa loo isticmaalaa in lagu soo saaro ilo farsamo oo kala duwan, qaybo farsamo iyo qalab.

Qaybaha korantada iyo korantada: waxaa loo isticmaalaa in lagu soo saaro qaybaha korantada iyo ilaha korantada.

Dhismaha iyo alaabta guriga: waxaa loo isticmaalaa in lagu soo saaro qalabka albaabka iyo daaqadaha iyo ilaha alaabta guriga, iwm.

Ku habboon samaynta ilo aad u waaweyn, sida ilo caleen ah oo is dulsaaran oo ku yaal cagaf-cagafyada, ilo gariiradda waaweyn iyo ilo togan oo waaweyn oo maraakiibta saaran.

CK75 Birta waxay u dhigantaaAISI 1075 steel carbonwaxaa ka mid ah:

ASTM A29 (1075)

ASTM A510 (1075)

ASTM A713 (1075)

SAE J403 (1075)

SAE J412 (1075)

EN 10132 Heerka SAE1075 qaboojiyaha duuban ee birta kaarboon CK75 C75 C75S strip birta guga waxay leedahay kaarboon ka kooban 0.7-0.8% taasoo ka dhigaysa bir kaarboon ujeedo badan leh oo leh sifooyin guga oo wanaagsan.

Sidaa darteed, waa mid aad loo isticmaalobirta kaarbooncodsiyada injineernimada oo kala duwan.

SAE1075 ama CK75 waxaa ku jira 0.7-0.8% kaarboon, 0.15-0.35% silicon, 0.6-0.9% manganese, iyo 0.03% fosfooraska iyo baaruud. Waxay haysataa

Birta guga ee CK75 waxay leedahay adkeysi ka wanaagsan, dhexroorka adag ee adag ee saliidda wuxuu gaari karaa 100 ~ 150mm.

CK75 ama C75 waxay ku habboon tahay samaynta ilo aad u waaweyn, sida ilo caleen ah oo is dulsaaran cagaf-cagafyada, ilo gariiradda waaweyn iyo ilo togan oo waaweyn oo maraakiibta saaran.

CK75 birta guga waa walxo bir kaarboon-sare ah. Waxyaabaha ay ka kooban tahay kiimikaad inta badan waxa ku jira kaarboon (C) inta u dhaxaysa 0.70-0.80%, Silicon (Si) waxa ku jira inta u dhaxaysa 0.10-0.35%, iyo manganese (Mn) waxa ku jira inta u dhaxaysa 0.60-0.80%.

Inta u dhaxaysa 0.90%, waxa ku jira fosfooraska (P) iyo baaruud (S) waxay ka yar yihiin 0.025% siday u kala horreeyaan.

Birta guga ee CK75 waxa ay leedahay barti wanaagsan iyo adkeysi waxaana inta badan loo isticmaalaa in lagu sameeyo ilo, garbaha, garbaha, mindiyaha iyo qaybaha kale iyo qalabka u baahan xoog sare oo xidho iska caabin.

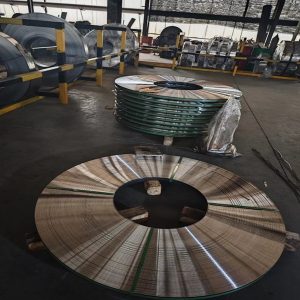

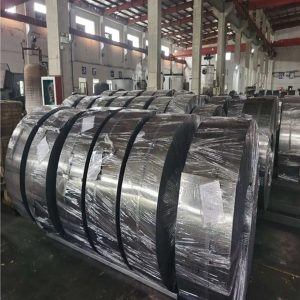

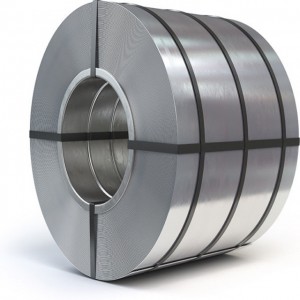

C75 C75s CK75 SAE 1075 birta birta guga

1,Shuruudaha Bixinta:

| Xaaladda gaarsiinta | Cabbirrada | Dusha sare | Cidhif |

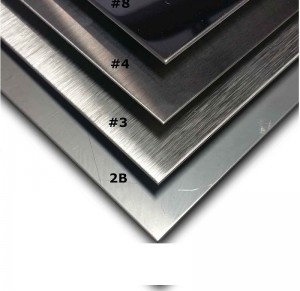

| 1. Qabow Gool | 1. Dhumucda: 0.09-8mm | Iftiimin | Kala goyn |

| 2. Qabow Rolled+Hydrogen la aasay | 2.Balac: 6-450mm | Wareeg | |

| 2 | Dhexroorka gariiradda gudaha: 300-800mm | Square |

2, Isbarbardhigga darajooyinka:

| FARSAMADA Isbarbardhigga SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | GERMANY DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | - | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL,SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3,Halka Kiimikada:

| Heerka | Darajo | Halabuurka Kiimikada (%) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | V | ||

| GB/T699 | 45 | 0.42 ilaa 0.50 | 0.17 ilaa 0.37 | 0.50 ilaa 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47 ilaa 0.55 | 0.17 ilaa 0.37 | 0.50 ilaa 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52 ilaa 0.60 | 0.17 ilaa 0.37 | 0.50 ilaa 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57 ilaa 0.65 | 0.17 ilaa 0.37 | 0.50 ilaa 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62 ilaa 0.70 | 0.17 ilaa 0.37 | 0.50 ilaa 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67 ilaa 0.75 | 0.17 ilaa 0.37 | 0.50 ilaa 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72 ilaa 0.80 | 0.17 ilaa 0.37 | 0.50 ilaa 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37 ilaa 0.44 | 0.17 ilaa 0.37 | 0.70 ilaa 1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42 ilaa 0.50 | 0.17 ilaa 0.37 | 0.70 ilaa 1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62 ilaa 0.70 | 0.17 ilaa 0.37 | 0.90 ilaa 1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95 ilaa 1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47 ilaa 0.55 | 0.17 ilaa 0.37 | 0.80 ilaa 1.10 | 0.035 | 0.035 | 0.90 ilaa 1.20 | 0.3 | 0.3 | 0.10 ilaa 0.20 |

| GB/T3077 | 50CrVA | 0.47 ilaa 0.54 | 0.17 ilaa 0.37 | 0.50 ilaa 0.80 | 0.025 | 0.025 | 0.80 ilaa 1.10 | 0.3 | 0.3 | 0.10 ilaa 0.20 |

| GB/T3077 | 75Cr1 | 0.7 ilaa 0.8 | 0.25 ilaa 0.5 | 0.50 ilaa 0.70 | 0.035 | 0.035 | 0.30 ilaa 0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52 ilaa 0.60 | 1.50 ilaa 2.00 | 0.60 ilaa 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56 ilaa 0.64 | 1.50 ilaa 2.00 | 0.60 ilaa 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |