Shiinaha DC51D ZF saxan bir galvanized saaraha iyo alaab-qeybiyaha | Ruiyi

Saxan bir galvanized Hot DC51D, sidoo kale loo magacaabay sidadhuuban kulul xaashi bir galvanizedDC51D+Z iyo Dip kulul zinc dahaarka saxan bir iyo gariiradda DC51D+ZF.Under Q/BQB 420 heerka steel, waxaa jira DC51D+Z,DC51D+ZF kaas oo loogu talagalay foorarsiga iyo tayada profile,DC52D+Z,DC52+ZF taaso ah tayada sawirida,DC53+Z,DC53+ZF kaas oo loogu talagalay sawirida qoto dheer tayada,DC54D+Z,DC54D+ZF kaas oo loogu talagalay tayada sawir qoto dheer,DC56D+Z,DC56D+ZF taaso loogu talagalay tayada sawir qoto dheer oo dheeraad ah.

DX51D waxay u taagan tahay xaashida galvanized. D-da hore waxay ka dhigan tahay birta fidsan ee samaynta qabowga. X macnaheedu waa gobolka duubitaanku waa mid aan xad lahayn. 51 waa tirada taxanaha ah ee birta. D-da labaad waxay ka dhigan tahay galvanized kulul oo la rusheeyey.

Haddii X uu noqdo C, oo ah DC51D, waxay la macno tahay in gobolka rogid substrate uu yahay wareeg qabow. Halka DD51D ay ka dhigan tahay in heerka rogrogmada substrate-ku uu yahay duubid kulul.

Waxa intaa dheer, way fududahay in la arko DX51D-Z, DX51D-ZF ama DX51D-AZ. Z macnaheedu waa in dahaarka galvanized uu yahay Zinc. ZF macnaheedu waa in dahaarka galvanized uu yahay aluminium Zn-Fe. AZ macnaheedu waa in daahan galvanized waa galvalume.

Gariiradaha galvanized DX51D waxaa loo soo saaray si waafaqsan EN 10346. Dhumucda dahaarka zinc waa kala duwan yahay iyadoo ku xiran shuruudaha macaamiisha.

DX51Dgariiradda galvanizedwaxaa si weyn loogu isticmaalaa soo saarista qaab-dhismeedka birta, saqafyada, profiles daaqadaha, dheecaanka iyo nidaamka hawo, caqabadaha waddooyinka, buundooyinka, iyo qalabka guriga (kiisas iyo qaybaha gudaha).

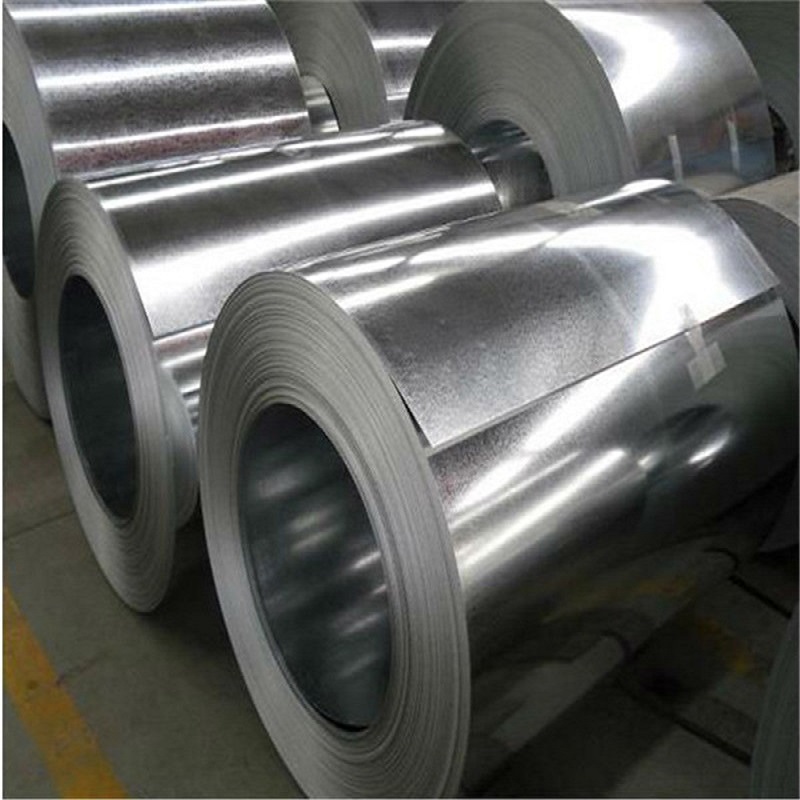

Alaabooyinka birta ah ee DX51D waxaa lagu soo saaraa gariiradaha 0.4-1.6 mm dhumucdiisuna tahay 950-1250 mm. Dhexroorka gudaha ee gariiraddu waa 600 ± 20 mm, dhexroorka dibaddana waa ilaa 1300 mm. Miisaanka gariiraddu waa ilaa 8 tan. Gariiradaha waxaa lagu bixiyaa geeso la gooyay (cidhifyada wax-shiidka sidoo kale waa suurtagal).

Halabuurka kiimikada iyo sifooyinka farsamada sida waafaqsan EN 10346

Ogow. U dulqaadashada cabbirrada iyo qaababka waxaa lagu qeexay EN 10143

Ogow. Shuruudaha samaynta iyo alxanka alaabta la dhammeeyey waa in la tixgeliyo marka la dalbanayo miisaanka dahaarka zinc.

Codsiyada iyo astaamaha waxaa lagu bixiyaa shaxda soo socota

| Heerka Birta | Codsiga | Muuqaal |

|---|---|---|

| DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | Ujeedo ganacsi | Kaarboon yar iyo/ama birta kaarboonka aadka u hooseeya |

| DC52D+Z (St04Z), DC52D+ZF | sawirid | |

| DC53D+Z (St05Z), DC53D+ZF | sawir qoto dheer | Bir kaarboon aadka u hooseeya |

| DC54D+Z (St06Z), DC54D+ZF | Sawir qoto dheer oo dheeraad ah | |

| DD54D+Z (St06ZR) | ||

| DC56D+Z (St07Z), DC56D+ZF | Sawir qoto dheer oo dheeraad ah oo sarreeya |

Halabuurka Kiimikada %:

| nooca birta bse | Darajo | QAABKA Kiimikada % | |||

|---|---|---|---|---|---|

| C | Si | Mn | P | ||

| xaashi bir ah oo qabow | DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | ≤0.10 | - | ≤0.50 | ≤0.035 |

| DC52D+Z (St04Z), DC52D+ZF | ≤0.08 | - | ≤0.45 | ≤0.030 | |

| DC53D+Z (St05Z), DC53D+ZF | ≤0.08 | - | ≤0.40 | ≤0.030 | |

| DC54D+Z (St06Z), DC54D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| DC56D+Z (St07Z), DC56D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| xaashi bir duuban oo kulul | DD51D+Z (St01ZR, St02ZR) | ≤0.10 | - | ≤0.50 | ≤0.035 |

| DD54D+Z (St06ZR) | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| Waxqabadka makaanikada iyo dhejinta dahaarka | |||||||

|---|---|---|---|---|---|---|---|

| Darajo | Bandhig faneedka | Xabagta dahaarka | |||||

| Xoog-soo-saarka MP | Xoojinta Xoojinta MP ≥ | Kordhinta Boqolleyda Jebinta Kadib (LO=80mm,b=20mm)% ≥ | Dhexroorka Xarunta Laacida ee soo socota Miisaanka Dahaarka (g/m2)c (a= dhumucdiisuna waxay tahay) | ||||

| L0=80mm,b=20mm | |||||||

| Hoosta soo socota dhumucda magac ahaan mm | ≤140/140 | >140/140-175/175 | >175/175 | ||||

| ≤0.7 | >0.7 | ||||||

| DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | - | 270-500 | 20 | 22 | 0a | 1a | 2a |

| DC52D+Z (St04Z), DC52D+ZF | 140-300 | 270 ~ 420 | 24 | 26 | |||

| DC53D+Z (St05Z), DC53D+ZF | 140 ~ 260 | 270 ~ 380 | 28 | 30 | |||

| DC54D+Z (St06Z) | 140 ~ 220 | 270-350 | 34 | 36 | |||

| DC54D+ZF | 32 | 34 | |||||

| DC56D+Z (St07Z) | 120 ~ 180 | 270-350 | 38 | 40 | |||

| DC56D+ZF | 36 | 38 | |||||

| Qaab dhismeedka dusha sare | Koodhka No. | Astaamaha | Codsiga |

|---|---|---|---|

| spangle caadiga ah | Z | Spangles waxay isku urursadeen daahan zinc ah xaaladaha caadiga ah ka dib galvanizing. | Ujeedooyinka ganacsiga |

| Spangle yar | X | Dusha sare ee spangles ka yar kuwa caadiga ah iyo ay sabab u tahay uumi la xakameeyey ee daahan zinc. | Codsiyada halka spangles caadiga ah aysan buuxin karin shuruudaha muuqaalka kore. |

| Maqaarku wuu dhaafay spangle | G | Qaab dhismeedka dusha sare ka dib daawaynta gudbinta maqaarka gaarka ah. | Codsiyada shuruudaha tayada sare ee dusha sare, sida taarikada saldhigga daahan midabka. |

| Maqaarku wuxuu dhaafay spangle yar | GX | ||

| Eber spangle | N | Ma jiro spangles muuqda oo ku yaal dusha sare ee daahan taasoo ka dhalatay habka wax soo saarka gaarka ah. | - |

| Zn-Fe daawaha | R | Ma laha spangle, cawl, caadi ahaan matte | Lagu dabaqi karo rinjiyeyn dheeraad ah |

| Daaweynta dusha sare | |

|---|---|

| Daaweynta Chromate (L) | Daawaynta Chromate waa daawaynta kiimikaad iyadoo ujeedadu tahay in laga hortago miridhku cadcad ee ka samaysan sagxadaha alaabta inta lagu jiro gaadiidka iyo kaydinta. |

| Saliid (Y) | Saliiddu waa inay ka hortagto miridhyo cad oo ka samaysan sagxadaha alaabta inta lagu jiro gaadiidka iyo kaydinta. |

| Daawaynta Chromate+ Saliid (LY) | Daawaynta Chromate+ Saliid (LY) Daawayntan saliidda leh ka dib daawaynta chromate-ka dusha sare waa si looga fogaado samaynta miridhku cadcad. |

Tayada dusha sare

| Lambarka lambarka. | Astaamaha |

|---|---|

| FB (O3) | t waxaa loo ogol yahay jiritaanka dhibco yar-yar oo nabaad guur ah, baro madow, calaamado xariijimo ah, cilladaha daawaynta chromate-ka yar iyo qaybo yar oo zinc ah. |

| FC (O4) | Meel nabaad guur ah lama ogola. Si kastaba ha noqotee, waxaa loo oggol yahay jiritaanka iftiinka iftiinka, xoqitaanka, calaamadaha qulqulka zinc, cilladaha daweynta chromate ee yar yar, halka dhinaca kale ay tahay inuu gaaro shuruudaha FB ugu yaraan. |

| FD (O5) | Dhinac ka mid ah tayada aadka u wanaagsan waa in uu sii xaddidaa cilladaha, kuwaas oo ah tayada muuqaalka ka dib rinjiyeynta ma saameynayso, dhinaca kale waa in uu gaaro shuruudaha FB ugu yaraan. |

Liiska tixraaca darajada birta ee heerarka, heerarka la soo xigtay iyo heerarka kale

| Q/BQB 420-2003 | EN10142:2000 EN10147:2000 EN10292:2000 | EN 10142:1990 EN 10147:1991 | JISG3302-1994 | ASTMA653M-2002 |

|---|---|---|---|---|

| DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | DC51D+Z,+ZF | FeP02GZ, ZF | SGCC | CS nooca C |

| DC52D+Z (St04Z), DC52D+ZF | DC52D+Z,+ZF | FeP03GZ, ZF | SGCC | CS nooca A, nooca B |

| DC53D+Z (St05Z), DC53D+ZF | DC53D+Z,+ZF | FeP05GZ, ZF | SGCD1 | FS nooca A, nooca B |

| DC54D+Z (St06Z), DC54D+ZF | DC54D+Z,+ZF | FeP06GZ, ZF | SGCD2 | DDS |

| DC56D+Z (St07Z), DC56D+ZF | DC56D+Z,+ZF | DX56D+Z,+ZF (SEW 021) | SGCD3 | EDDS |

| Q/BQB 420 galvanized kulul-muquufin/zinc-birta daawaha/zinc-magnesium dahaar xaashi bir dahaarka leh iyo strip | ||||

| Magaca birta | Qulqulka kulul ee galvanized/qabow duuban substrate | Qulqulka kulul ee galvanized/ kulul duuban | Zinc bir daawaha | Zinc magnesium alloy |

| Bir khafiif ah ama bir aan isdhexgal lahayn | DC51D+Z | DD51D+Z | DC51D+ZF | DC51D+ZM |

| DC52D+Z | DC52D+ZF | DC52D+ZM | ||

| DC53D+Z | DC53D+ZF | DC53D+ZM | ||

| DC54D+Z | DC54D+ZF | DC54D+ZM | ||

| DC56D+Z | DC56D+ZF | DC56D+ZM | ||

| DC57D+Z | DC57D+ZF | DC57D+ZM | ||

| Bir dhismeed kaarboon ama bir daawaha hoose | S220GD+Z | S220GD+ZF | S220GD+ZM | |

| S250GD+Z | S250GD+ZF | S250GD+ZM | ||

| S280GD+Z | S280GD+ZF | S280GD+ZM | ||

| S320GD+Z | S320GD+ZF | S320GD+ZM | ||

| S350GD+Z | S350GD+ZF | S350GD+ZM | ||

| S550GD+Z | S550GD+ZM | |||

| Bir xoog sare leh oo bilaa interstitial ah | HC180YD+Z | HC180YD+ZF | HC180YD+ZM | |

| HC220YD+Z | HC220YD+ZF | HC220YD+ZM | ||

| B240P1D+Z | B240P1D+ZF | B240P1D+ZM | ||

| B260LYD+Z | B260LYD+ZF | B260LYD+ZM | ||

| HC260YD+Z | HC260YD+ZF | HC260YD+ZM | ||

| dubi birta adag | HC180BD+Z | HC180BD+ZF | HC180BD+ZM | |

| HC220BD+Z | HC220BD+ZF | HC220BD+ZM | ||

| HC260BD+Z | HC260BD+ZF | HC260BD+ZM | ||

| HC300BD+Z | HC300BD+ZF | HC300BD+ZM | ||

| aluminium hoose birta xoogga sare | HC260LAD+Z | HC260LAD+ZF | HC260LAD+ZM | |

| HC300LAD+Z | HC300LAD+ZF | HC300LAD+ZM | ||

| HC340LAD+Z | HD340LAD+Z | HC340LAD+ZF | HC340LAD+ZM | |

| HC380LAD+Z | HC380LAD+ZF | HC380LAD+ZM | ||

| HC420LAD+Z | HD410LAD+Z | HC420LAD+ZF | HC420LAD+ZM | |

| HC460LAD+Z | HC460LAD+ZF | HC460LAD+ZM | ||

| HC500LAD+Z | HC500LAD+ZF | HC500LAD+ZM | ||

| HD550LAD+Z | ||||

| Duplex birta | HC250/450DPD+Z | HC250/450DPD+ZF | HC250/450DPD+ZM | |

| HC300/500DPD+Z | HC300/500DPD+ZF | HC300/500DPD+ZM | ||

| HC280/590DPD+Z | HC280/590DPD+ZF | HC280/590DPD+ZM | ||

| HC340/590DPD+Z | HC340/590DPD+ZF | HC340/590DPD+ZM | ||

| B340/590DPD+Z | B340/590DPD+ZF | B340/590DPD+ZM | ||

| HC420/780DPD+Z | HC420/780DPD+ZF | |||

| HC500/780DPD+Z | HC500/780DPD+ZF | |||

| HC550/980DPD+Z | HC550/980DPD+ZF | |||

| HC650/980DPD+Z | HC650/980DPD+ZF | |||

| HC700/980DPD+Z | HC700/980DPD+ZF | |||

| HC740/1180DPD+Z | HC740/1180DPD+ZF | |||

| HC820/1180DPD+Z | HC820/1180DPD+ZF | |||

| is-beddelka sababay birta balaastikada | HC380/590TRD+Z | HC380/590TRD+ZF | ||

| HC400/690TRD+Z | HC400/690TRD+ZF | |||

| HC420/780TRD+Z | HC420/780TRD+ZF | |||

| birta wajiga adag | HC570/780CPD+Z | HD660/760CPD+Z | ||

| HC780/980CPD+Z | ||||

| bir qallafsan | HC600/980QPD+Z | |||

| HC600/980QP-ELD+Z | ||||

| HC820/1180QPD+Z | ||||

| HC820/1180QP-ELD+Z | ||||