China Special Design for Zinc Rusting - DC51D ZF Galvanized steel plate Coil - Ruiyi Manufacturer and Supplier | Ruiyi

China Special Design for Zinc Rusting - DC51D ZF Galvanized steel plate Coil - Ruiyi Manufacturer and Supplier | Ruiyi Detail:

Hot dip galvanized steel plate DC51D,also named as hot dip galvanized steel sheet DC51D+Z and hot dip zinc coated steel plate and coil DC51D+ZF.Under Q/BQB 420 steel standard,there are DC51D+Z,DC51D+ZF which is for bending and profiling quality,DC52D+Z,DC52+ZF which is for drawing quality,DC53+Z,DC53+ZF which is for deep drawing quality,DC54D+Z,DC54D+ZF which is for special deep drawing quality,DC56D+Z,DC56D+ZF which is for extra deep drawing quality.

DX51D stands for galvanized steel sheet. The first D means flat steel for cold forming. The X means the rolling state is indefinite. 51 is the series number of the steel. The second D means hot dipped galvanized.

If the X become C, namely DC51D, it means that the substrate rolling state is cold rolling. While DD51D means that the rolling rolling state of the substrate is hot rolling.

What’s more, it’s easy to see DX51D-Z, DX51D-ZF or DX51D-AZ. The Z means that the galvanized coating is Zinc. ZF means that the galvanized coating is Zn-Fe alloy. AZ means that the galvanized coating is galvalume.

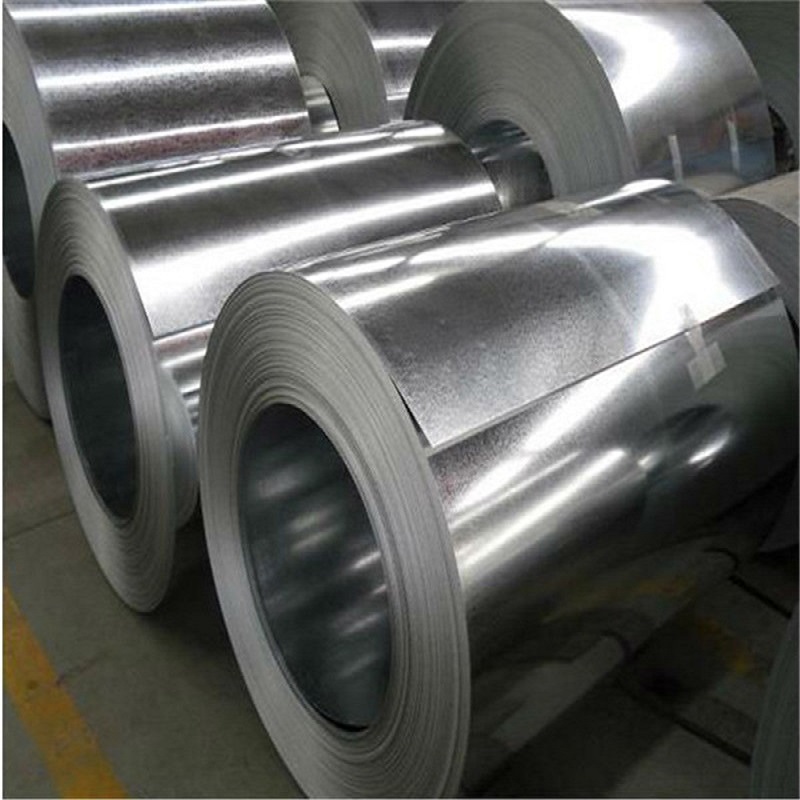

DX51D galvanized coils are produced according to EN 10346. The thickness of the zinc coating varies depending on consumers’ requirements.

DX51D galvanized coils are widely used for the production of steel structures, roofs, window profiles, drainage and ventilation systems, roads barriers, bridges, and household appliances (cases and internal parts).

DX51D steel products are produced in coils 0.4-1.6 mm thick and 950-1250 mm wide. The inner diameter of the coil is 600±20 mm and outer diameter is up to 1300 mm. Coil weight is up to 8 tons. Coils are supplied with cut edges (mill edges are also possible).

Chemical composition and mechanical properties according to EN 10346

Note. Tolerances for dimensions and shapes are outlined in EN 10143 (tolerances for width are for coils a minimum of 0.7 mm thick)

Note. Requirements for forming and weldability of finished products should be taken into consideration when ordering the weight of zinc coating.

Applications and features are given as following table

| Steel Grade | Application | Feature |

|---|---|---|

| DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | Commercial purpose | Low carbon and/or ultra-low carbon steel |

| DC52D+Z (St04Z), DC52D+ZF | Drawing | |

| DC53D+Z (St05Z), DC53D+ZF | Deep drawing | Ultra-low carbon steel |

| DC54D+Z (St06Z), DC54D+ZF | Extra deep drawing | |

| DD54D+Z (St06ZR) | ||

| DC56D+Z (St07Z), DC56D+ZF | Supreme extra deep drawing |

Chemical Composition %:

| bse metal type | Grade | CHEMICAL COMPOSITION % | |||

|---|---|---|---|---|---|

| C | Si | Mn | P | ||

| cold rolled steel sheet | DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | ≤0.10 | – | ≤0.50 | ≤0.035 |

| DC52D+Z (St04Z), DC52D+ZF | ≤0.08 | – | ≤0.45 | ≤0.030 | |

| DC53D+Z (St05Z), DC53D+ZF | ≤0.08 | – | ≤0.40 | ≤0.030 | |

| DC54D+Z (St06Z), DC54D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| DC56D+Z (St07Z), DC56D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| hot rolled steel sheet | DD51D+Z (St01ZR, St02ZR) | ≤0.10 | – | ≤0.50 | ≤0.035 |

| DD54D+Z (St06ZR) | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| Mechanical performances and coating adhesiveness | |||||||

|---|---|---|---|---|---|---|---|

| Grade | Mechanical performances | Coating Adhesiveness | |||||

| Yield Strength MP | Tensile Strength MP ≥ | After Breakage Percent Elongation (LO=80mm,b=20mm)% ≥ | Bending Center Diameter in Following Coating Weight (g/m2)c (a=plate thickness) | ||||

| L0=80mm,b=20mm | |||||||

| Under following nominal thickness mm | ≤140/140 | >140/140~175/175 | >175/175 | ||||

| ≤0.7 | >0.7 | ||||||

| DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | – | 270~500 | 20 | 22 | 0a | 1a | 2a |

| DC52D+Z (St04Z), DC52D+ZF | 140~300 | 270~420 | 24 | 26 | |||

| DC53D+Z (St05Z), DC53D+ZF | 140~260 | 270~380 | 28 | 30 | |||

| DC54D+Z (St06Z) | 140~220 | 270~350 | 34 | 36 | |||

| DC54D+ZF | 32 | 34 | |||||

| DC56D+Z (St07Z) | 120~180 | 270~350 | 38 | 40 | |||

| DC56D+ZF | 36 | 38 | |||||

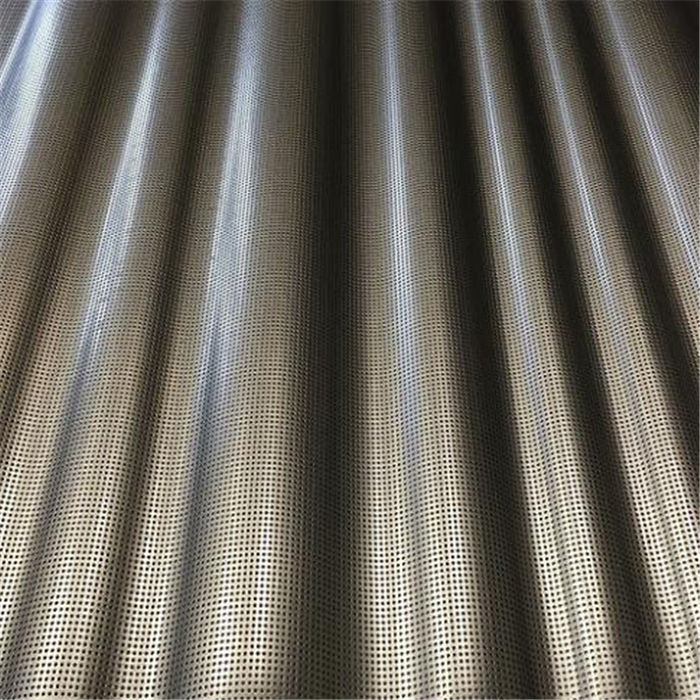

| Surface structure | Code No. | Features | Application |

|---|---|---|---|

| Conventional spangle | Z | Spangles condensated on zinc coating under normal conditions after galvanizing. | Commercial purposes |

| Small spangle | X | Surface in spangles smaller than conventional ones and due to controlled condensation of zinc coating. | Applications where conventional spangles cannot meet the surface appearance requirements. |

| Skin passed spangle | G | Surface structure after special skin pass treatment. | Applications of high surface quality requirements, such as color coating base plates. |

| Skin passed small spangle | GX | ||

| Zero spangle | N | No visible spangles on coating surface as a result of a special production process. | – |

| Zn-Fe alloy | R | No spangle, gray, normally matte | Applicable to further painting |

| Surface treatment | |

|---|---|

| Chromate treatment (L) | Chromate treatment is a chemical treatment with an aim to prevent white rusts formed on product surfaces during transportation and storage. |

| Oiling (Y) | Oiling is to prevent white rusts formed on product surfaces during transportation and storage. |

| Chromate treatment+ Oiling (LY) | Chromate treatment+ Oiling (LY) This treatment with oiling after surface chromate treatment is to further avoid the forming of white rusts. |

Surface quality

| Code No. | Features |

|---|---|

| FB (O3) | t is allowed for the existence of small erosion spots, dark spots, strip marks, minor chromate treatment defects and small zinc particles. |

| FC (O4) | No erosion spot is allowed. However, it is allowed for the existence of light impression, scratches, zinc flow ripple marks, minor chromate treatment defects in small range, while the other side must reach FB requirements at least. |

| FD (O5) | One side of relatively good quality must further restrict on defects, namely appearance quality after painting is not affected, and the other side must reach FB requirements at least. |

Steel grade reference list of the standards, the cited standards and other standards

| Q/BQB 420-2003 | EN10142:2000 EN10147:2000 EN10292:2000 | EN 10142:1990 EN 10147:1991 | JISG3302-1994 | ASTMA653M-2002 |

|---|---|---|---|---|

| DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | DC51D+Z, +ZF | FeP02GZ, ZF | SGCC | CS type C |

| DC52D+Z (St04Z), DC52D+ZF | DC52D+Z, +ZF | FeP03GZ, ZF | SGCC | CS type A, type B |

| DC53D+Z (St05Z), DC53D+ZF | DC53D+Z, +ZF | FeP05GZ, ZF | SGCD1 | FS type A, type B |

| DC54D+Z (St06Z), DC54D+ZF | DC54D+Z, +ZF | FeP06GZ, ZF | SGCD2 | DDS |

| DC56D+Z (St07Z), DC56D+ZF | DC56D+Z, +ZF | DX56D+Z, +ZF (SEW 021) | SGCD3 | EDDS |

| Q/BQB 420 Hot-dip galvanized/zinc-iron alloy/zinc-magnesium alloy coated steel sheet and strip | ||||

| Steel name | Hot dip galvanized/cold rolled substrate | Hot dip galvanized/ hot rolled substrate | Zinc iron alloy | Zinc magnesium alloy |

| Mild steel or interstitial-free steel | DC51D+Z | DD51D+Z | DC51D+ZF | DC51D+ZM |

| DC52D+Z | DC52D+ZF | DC52D+ZM | ||

| DC53D+Z | DC53D+ZF | DC53D+ZM | ||

| DC54D+Z | DC54D+ZF | DC54D+ZM | ||

| DC56D+Z | DC56D+ZF | DC56D+ZM | ||

| DC57D+Z | DC57D+ZF | DC57D+ZM | ||

| Carbon structural steel or low alloy steel | S220GD+Z | S220GD+ZF | S220GD+ZM | |

| S250GD+Z | S250GD+ZF | S250GD+ZM | ||

| S280GD+Z | S280GD+ZF | S280GD+ZM | ||

| S320GD+Z | S320GD+ZF | S320GD+ZM | ||

| S350GD+Z | S350GD+ZF | S350GD+ZM | ||

| S550GD+Z | S550GD+ZM | |||

| Interstitial-free high-strength steel | HC180YD+Z | HC180YD+ZF | HC180YD+ZM | |

| HC220YD+Z | HC220YD+ZF | HC220YD+ZM | ||

| B240P1D+Z | B240P1D+ZF | B240P1D+ZM | ||

| B260LYD+Z | B260LYD+ZF | B260LYD+ZM | ||

| HC260YD+Z | HC260YD+ZF | HC260YD+ZM | ||

| bake hardened steel | HC180BD+Z | HC180BD+ZF | HC180BD+ZM | |

| HC220BD+Z | HC220BD+ZF | HC220BD+ZM | ||

| HC260BD+Z | HC260BD+ZF | HC260BD+ZM | ||

| HC300BD+Z | HC300BD+ZF | HC300BD+ZM | ||

| low alloy high strength steel | HC260LAD+Z | HC260LAD+ZF | HC260LAD+ZM | |

| HC300LAD+Z | HC300LAD+ZF | HC300LAD+ZM | ||

| HC340LAD+Z | HD340LAD+Z | HC340LAD+ZF | HC340LAD+ZM | |

| HC380LAD+Z | HC380LAD+ZF | HC380LAD+ZM | ||

| HC420LAD+Z | HD410LAD+Z | HC420LAD+ZF | HC420LAD+ZM | |

| HC460LAD+Z | HC460LAD+ZF | HC460LAD+ZM | ||

| HC500LAD+Z | HC500LAD+ZF | HC500LAD+ZM | ||

| HD550LAD+Z | ||||

| Duplex steel | HC250/450DPD+Z | HC250/450DPD+ZF | HC250/450DPD+ZM | |

| HC300/500DPD+Z | HC300/500DPD+ZF | HC300/500DPD+ZM | ||

| HC280/590DPD+Z | HC280/590DPD+ZF | HC280/590DPD+ZM | ||

| HC340/590DPD+Z | HC340/590DPD+ZF | HC340/590DPD+ZM | ||

| B340/590DPD+Z | B340/590DPD+ZF | B340/590DPD+ZM | ||

| HC420/780DPD+Z | HC420/780DPD+ZF | |||

| HC500/780DPD+Z | HC500/780DPD+ZF | |||

| HC550/980DPD+Z | HC550/980DPD+ZF | |||

| HC650/980DPD+Z | HC650/980DPD+ZF | |||

| HC700/980DPD+Z | HC700/980DPD+ZF | |||

| HC740/1180DPD+Z | HC740/1180DPD+ZF | |||

| HC820/1180DPD+Z | HC820/1180DPD+ZF | |||

| transformation induced plasticity steel | HC380/590TRD+Z | HC380/590TRD+ZF | ||

| HC400/690TRD+Z | HC400/690TRD+ZF | |||

| HC420/780TRD+Z | HC420/780TRD+ZF | |||

| Complex phase steel | HC570/780CPD+Z | HD660/760CPD+Z | ||

| HC780/980CPD+Z | ||||

| hardened ductile steel | HC600/980QPD+Z | |||

| HC600/980QP-ELD+Z | ||||

| HC820/1180QPD+Z | ||||

| HC820/1180QP-ELD+Z | ||||

Product detail pictures:

Related Product Guide:

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for China Special Design for Zinc Rusting - DC51D ZF Galvanized steel plate Coil - Ruiyi Manufacturer and Supplier | Ruiyi, The product will supply to all over the world, such as: Zurich , French , Czech , Providing Quality Items, Excellent Service, Competitive Prices and Prompt Delivery. Our products and solutions are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.