1100 Ho potoloha aluminium selikalikoe Moetsi le Mofani

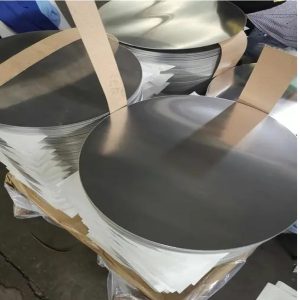

Selika-likoe sa aluminium se ohiang ke sekotoana se chitja sa aluminium se ohloang holim'a lesela ho etsa sebopeho se lekanang. Ts'ebetso ena e tsejoa e le ho bilika ha tšepe kapa ho etsa spin.

Ts'ebetso ea ho ohla e kenyelletsa ho potoloha disk ea aluminium holim'a lathe ha sesebelisoa se hatelloa khahlanong le eona, ho etsa hore butle-butle e be sebopeho se chitja.

Sedikadikwe se hlahisoang se ka sebelisoa bakeng sa lits'ebetso tse fapaneng joalo ka li-cookware, lisebelisoa tsa mabone le likarolo tsa koloi.

Botenya le bophara ba selikalikoe li ka etsoa ho latela litlhoko tse khethehileng tsa kopo.

Aluminium ke thepa e tsebahalang bakeng sa ho bilika ka lebaka la boima ba eona bo bobebe, bo tšoarellang le ho hanyetsa kutu.

Selikalikoe sa aluminium sa spinning ke sehlahisoa sa aluminium se entsoeng ka mokhoa oa ho ohla 'me se na le mefuta e mengata ea lisebelisoa.

Mokhoa oa ho ohla ke mokhoa oa ho sebetsa ka tšepe. Ka ho potoloha le khatello ea mochine o ohlang, lisebelisoa tsa aluminium alloy li senyeha butle-butle tlas'a ketso ea hlobo, 'me qetellong ho fumanoa sebopeho se hlokahalang.

Ho potoloha ha aluminium ho na le melemo e mengata, joalo ka ho sebetsa hantle, ho nepahala le moruo. Kaha thepa ea aluminium alloy ka boeona e na le litšobotsi tsa boima bo bobebe, matla a phahameng, le ho hanyetsa kutu, li-circles tsa aluminium tse pota-potileng li ka finyella litlhoko tsa ts'ebetso ea thepa likarolong tse sa tšoaneng.

Lefapheng la tlhahiso ea likoloi, li-circles tsa aluminium tse pota-potileng li ka sebelisoa ho etsa 'mele ea likoloi, mamati, marulelo le likarolo tse ling, ho thusa ho finyella lipakane tsa ho fokotsa boima ba koloi, ho boloka matla le ho sireletsa tikoloho.

Lebaleng la lifofane,ho potoloha lidikadikwe tsa aluminiume ka sebelisoa ho etsa likarolo tse kang li-fuselage tsa sefofane le lifola tsa moea, 'me e na le thepa e ntle ea mochini le ho hanyetsa ho bola.

Ho phaella moo, tšimong ea kaho, li-circles tsa aluminium tse pota-potileng li ka sebelisoa ho etsa mamati, lifensetere, marako a likharetene, li-balcony le likarolo tse ling tsa mohaho ho finyella litlhoko tsa ts'ebetso ea mohaho le ponahalo.

Ho potoloha Aluminium Circle ho bolela sedikadikwe sa aluminium se sebedisetswang ho ohla. E lula e sebelisa li-discs tsa aluminium tse batang tse entsoeng ka ho seha likhoele tsa aluminium ka leloala le batang.

Alloy e tloaelehileng e batang e pota-potileng A1050 1060 1070 1100 3003 3015 5052, joalo-joalo, e na le ts'ebetso e ntle le ho hanyetsa kutu.

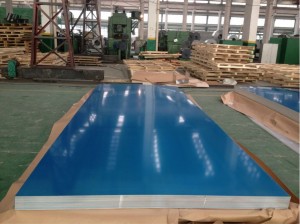

Tlhaloso ea Sehlahisoa sa Aluminium Circles:

- Alloy: 1050, 1060, 1070, 1100, 3002, 3003, 3004, 5052A, 5052, 5754, 6061

- Ho thatafala: O, H12, H14, H16, H18

- Botenya: 0.012" - 0.15" (0.3mm - 4mm)

- Bophara: 3.94" - 38.5 ″ (80mm -2000mm)

- Bokaholimo: E hloekisitsoe, e khanyang, e sa tloaelehang

- Tšebeliso: E loketse ho etsa lipitsa, lipane, literei tsa pizza, lipane tsa phae, lipane tsa kuku, likoahelo, likotlolo, libeisine, li-fryer, li-reflectors tse khanyang.

- Lisebelisoa tsa Stamping li kenyelletsa: tšepe, tšepe, galvanized, aluminium, alloy ea aluminium le lisebelisoa tse ling.

A1050li-discs tsa aluminiumhaholo-holo li entsoe ka aluminium 'me li na le likaroloana tse ling tsa motsoako, tse fanang ka bohloeki bo phahameng, ductility e ntle, matla le ho tiea.

A1050 aluminium discs ho pharaletseng sebelisoa masimong a mangata ka lebaka la tshebetso bona e babatsehang. Mohlala, e ka sebelisoa ho etsa likarolo tsa likoloi, lifofane, lihlahisoa tsa sesole le tsa elektroniki, joalo ka lihlopha tsa likoloi, liphaposi tsa lifofane, likarolo tsa enjene, lisebelisoa tsa sesole le liboto tsa potoloho, jj.

Ho phaella moo, li-discs tsa aluminium tsa A1050 li boetse li sebelisoa ka tloaelo ha ho etsoa litlhoko tsa letsatsi le letsatsi, lisebelisoa tsa mabone, liphanele tse bonahatsang, mekhabiso, lijana tsa indasteri ea lik'hemik'hale, licheso tsa mocheso, lipontšo le lihlahisoa tse ling.

Libakeng tsena, ductility e phahameng le matla a aluminium discs A1050 e nolofalletsa ho sebetsana ka katleho le libopeho tse sa tšoaneng tse rarahaneng le meralo ea meralo.

1070 aluminium disc ke letlapa le chitja le sebetsitsoeng ho tloha 1070 aluminium alloy. 1070 aluminium alloy e na le letoto la lisebelisoa tse ntle tsa 'mele le tsa lik'hemik'hale, joalo ka letsoalo le tlase, motlakase o motle le motlakase oa mocheso, ho hanyetsa kutu e ntle haholo, le thepa e ntle ea ho sebetsa ka polasetiki.

Alloy e loketse mekhoa e fapaneng ea ts'ebetso, ho kenyelletsa khase, TIG le welding ea matheba, 'me e ka eketsa matla ka deformation e batang.

Likopong, 1070li-discs tsa aluminiumli sebelisoa haholo libakeng tse ngata ka lebaka la thepa ea tsona e ikhethang.

Lefapheng la motlakase le lisebelisoa tsa elektronike, hangata e sebelisoa likarolong tse kang lithapo, lithapo, li-transformer le li-electrolytic capacitor foil ka lebaka la thepa ea eona e ntle ea conductive.

Indastering ea lik'hemik'hale, khanyetso ea eona e ntle ea kutu e e etsa khetho e nepahetseng bakeng sa lisebelisoa tsa lik'hemik'hale, litanka tsa polokelo le liphaephe.

Ka nako e ts'oanang, hobane motsoako oa aluminium oa 1070 o bonolo ho o bōpa le ho o sebetsa, o boetse o atisa ho sebelisoa ha ho etsoa mokhabiso oa meralo, mamati a aluminium alloy le lifensetere, le lihlahisoa tse ling.

1100 aluminium selikalikoe ke mofuta oa motsoako oa aluminium o nang le 99% ea aluminium le 1% ea likarolo tse ling tse kang tšepe, silicon, koporo le zinki.

Ke thepa e bonolo le e ductile e sebelisoang hangata lits'ebetsong tse fapaneng joalo ka li-cookware, libonela-mabone, matšoao a sephethephethe le lisebelisoa tsa ho lokisa lik'hemik'hale.

Selika-likoe sa aluminium sa 1100 se na le khanyetso e ntle haholo ea kutu, conductivity e phahameng ea mocheso, le conductivity e ntle ea motlakase. Hape ho bonolo ho theha, ho cheselletsa le mochini, ho e etsa khetho e tsebahalang bakeng sa liindasteri tse ngata.

Metal spinning, asymmetrical rotational forming process for sheet metal. Hangata e sebelisoa ho etsa thepa ea ka tlung, mabone, lisebelisoa tsa tafole, sefofane le liindasteri tse ling.

Ts'ebetso ea tlhahiso ea ho ohla hangata e hloka li-discs tse batang (tseo hape li bitsoang CC aluminium discs). Limaraka tse sebelisoang ka tloaelo ke: 1050, 1060, 1100, 3003, 5052, 8011. ho ohla ho ka aroloa ka ho ohla ka letsoho le ho ohia ha CNC.

Ho ohla ka letsoho: mokhoa oa ho etsa li-spinning ke mokhoa oa khale oa ho theha, o nang le potoloho e khutšoanyane ea tlhahiso, litlhoko tse phahameng tsa theknoloji, li ka sebelisoa lisebelisoa tse tloaelehileng tsa mochine o nang le hlobo e bonolo ea ho etsa likarolo tse rarahaneng, 'me e ka ba tse loketseng bakeng sa tšepe, aluminium, koporo, le lisebelisoa tse ling tse fapaneng tsa tšepe, ho boloka thepa e tala le litšenyehelo tsa lisebelisoa, ho khutsufatsa nako ea ho sebetsa. Kamehla basebetsi ba sebelisa lehong kapa tšepe ho qeta ho ohla.

CNC spinning (Automatic spinning): CNC spinning forming ke ts'ebeliso ea litsi tsa phetolo tsa CNC ho fihlela metsamao e fapaneng e hlokahalang bakeng sa ho ohla, 'me ts'ebeliso ea liphetoho tsa eona tsa morao-rao ho ntlafatsa boleng ba likarolo, ha ho thetheha khahlano le lefu ho ka sebetsoa ka kotloloho mochining oa CNC. sesebelisoa. Haholo-holo e loketse lihlahisoa tse nchafalitsoeng khafetsa kapa tlhahiso e ngata ea spin forming process ho khetha li-parameter tse ntle ka ho fetisisa tsa ts'ebetso le trajectory.

Lisebelisoa tsa aluminium tse pota-potileng: lijana tsa ho baka, lipitsa tsa kofi, li-steamers, lipane, lipitsa tsa sieve, likotlolo, lijana tsa veine, li-teapot, li-vase, pane ea ho halika.

Jwaloka setsebi sa profeshenale sa moetsi wa pampiri wa aluminium, feme ya rona e tla ba le taolo e ntle mabapi le boholo ba koro le bolelele ba master roll ya aluminium coil ho etsa bonnete ba hore letlapa le pota-potileng la aluminium le ho ohla hantle, le ho qoba dintho tse mpe tse kang. mohlala oa lekhapetla la lamunu, moeli o sothehileng le sekhahla se phahameng sa ho etsa litsebe se ka 'nang sa etsahala ts'ebetsong ea morao-rao.

Alloy, boemo le ts'ebetso ea coil ea aluminium li laoloa ka thata le ho lekoa ho netefatsa ho nepahala le ho fapana ha li-disk tsa aluminium tse fanoeng.

Lidikadikwe tsa aluminium tse bilikang, tse tsejoang hape e le spun aluminium circles. Mokhoa oa ho ohla li-circles tsa aluminium o kenyelletsa ho sebelisa lesela ho ohla disc e bataletseng ea aluminium ka lebelo le phahameng ha e ntse e e etsa sebopeho sa selikalikoe.

Ke maemo afe a ikhethileng a ts'ebeliso ea li-cining tsa aluminium tse potolohang indastering ea likoloi?

Maemo a ikhethileng a ts'ebeliso ea li-circles tsa aluminium tse potolohang indastering ea likoloi a ruile haholo. Mehlala e meng ea bohlokoa ea ts'ebeliso ke ena:

Likarolo tsa 'mele:Li-discs tsa aluminium tsa Spun kapa Spinning aluminium circles li phetha karolo ea bohlokoa tlhahisong ea 'mele oa likoloi.

Li ka sebelisoa ho etsa liphanele tsa 'mele, mamati, marulelo le likarolo tse ling, tse sa fokotseng boima ba koloi feela, empa hape li thusa ho ntlafatsa katleho ea mafura le ts'ebetso ea koloi.

Likarolo tsa chassis:Lits'ebetsong tsa chassis, li-discs tsa aluminium tse spun le tsona li sebelisoa haholo ho etsa likarolo tse fapaneng. Ho bobebe ha likarolo tsena ho thusa ho ntlafatsa ts'ebetso le botsitso ba koloi ha ho ntse ho fokotsa tšebeliso ea mafura le mesi.

Sistimi ea enjene le phetisetso:Ho potoloha li-circles tsa aluminium le hona ho phetha karolo ea bohlokoa ho etseng lienjineri. Li ka sebelisoa ho etsa likarolo tsa enjene, joalo ka li-blade tsa turbine, li-disk tsa turbine, joalo-joalo, ho ntlafatsa ts'ebetso ea enjene le bophelo.

Ntle le moo, tsamaisong ea phetisetso, li-circles tsa aluminium tse spun li boetse li sebelisoa ho etsa likarolo tsa bohlokoa joalo ka li-clutch le likere tsa gearbox.

Likarolo tsena li na le matla a phahameng le ho hanyetsa phello e ntle, tse thusang ho ntlafatsa katleho ea phetisetso le ho tšepahala ha koloi.

Litsamaiso tsa mafura le mesi:Li-circuits tsa aluminium tse potolohang le tsona li ka sebelisoa ho etsa likarolo tsa sistimi ea peterole le lits'ebetso tsa mesi, joalo ka litanka tsa mafura, lipeipi tsa ho tima, jj.

Likarolo tsena ha li na ts'ebetso e ntle ea kutu, empa hape li hanela khoholeho ea mobu ka mafura le mesi, ho netefatsa ts'ebetso e bolokehileng le e tsitsitseng ea koloi.

Ntle le moo, li-circle tsa aluminium tse pota-potileng li ka boela tsa sebelisoa ho etsa likoloi ho etsa liphanele tsa ho kenya molumo, li-cylinder block, li-hubs tsa mabili le likarolo tse ling ho fihlela litlhoko tsa koloi bakeng sa boima bo bobebe, matla a phahameng le ho hanyetsa kutu.