China Ck75 Steel C75s C75 SAE 1075 spring steel strip

CK75 steel ke sesebediswa sa tshepe sa k'habone e phahameng, mme C e bontsha hore ho na le carbon content ya 0.75%. Lintho tse ling tse ka sehloohong tsa alloying li kenyelletsa manganese, silicon, phosphorus, joalo-joalo.

CK75 Steel e na le thepa le lits'ebetso tse latelang:

Litšobotsi tsa tšepe ea CK75:

E na le matla a ho hlahisa lihlahisoa tse phahameng le matla a ho tsitsa 'me e khona ho mamella meroalo e meholo e tsitsitseng.

E na le thepa e ntle ea mechine le thepa ea phekolo ea mocheso, 'me e loketse ho etsa liliba tse hlokang matla a phahameng le ho hanyetsa ho apara.

Ho thatafala ha eona ho ka fetoloa ka phekolo ea mocheso ho finyella litlhoko tsa maemo a fapaneng a kopo.

E na le matla a itseng a khoheli 'me e ka sebelisoa ho etsa likarolo tsa motlakase.

E na le khanyetso e ntle ea kutu 'me e ka boloka sebaka se setle sa bokaholimo le boemo ba leholimo tlas'a maemo a itseng.

Tšebeliso ea CK75 Steel:

Indasteri ea likoloi: e sebelisetsoang ho etsa liliba tsa chassis ea likoloi le likarolo tsa sistimi e emisitsoeng.

Ho etsa mechini: e sebelisetsoang ho etsa liliba tse fapaneng tsa mochini, likarolo tsa mochini le lisebelisoa.

Libaka tsa elektroniki le tsa motlakase: tse sebelisetsoang ho etsa likarolo tsa motlakase le liliba tse tsamaisang.

Kaho le thepa ea ka tlung: e sebelisetsoang ho etsa lisebelisoa tsa thepa ea mamati le lifensetere le liliba tsa thepa ea ka tlung, jj.

E loketse ho etsa liliba tse kholo haholo, joalo ka liliba tsa makhasi a phuthetsoeng holim'a li-bulldozers, liliba tse kholo tsa coil le liliba tse kholo tsa torsion likepeng.

CK75 Steel li lekana leAISI 1075 tšepe ea carbonkenyeletsa:

ASTM A29 (1075)

ASTM A510 (1075)

ASTM A713 (1075)

SAE J403 (1075)

SAE J412 (1075)

EN10132 Standard SAE1075 leqhoa le batang la tšepe le pholileng CK75 C75 C75S Spring steel strip e na le carbon content ea 0.7-0.8% e etsang hore e be tšepe e mengata ea carbon e nang le lisebelisoa tse ntle tsa selemo.

Ka hona, e sebelisoa hangatatšepe ea carbonmefuteng e mengata ea lisebelisoa tsa boenjiniere.

SAE1075 kapa CK75 e na le 0.7-0.8% carbon, 0.15-0.35% silicon, 0.6-0.9% manganese, le 0.03% phosphorus le sulphur. E na le matla a matla a 1230-1340 MPa, ho hlahisa matla a 1130-1240 MPa, le boima ba 57-63 HRC.

CK75 ea tšepe ea selemo e na le boima bo betere, bophara bo thata bo thata ka har'a oli bo ka fihla ho 100 ~ 150mm.

CK75 kapa C75 e Lokela ho etsa liliba tse kholo haholo, joalo ka liliba tsa makhasi a bokeletsoeng holim'a li-bulldozers, liliba tse kholo tsa likhoele le liliba tse kholo tsa torsion likepeng.

CK75 spring steel ke thepa e phahameng ea carbon steel. Sebopeho sa eona sa lik'hemik'hale se kenyelletsa haholo-holo carbon (C) dikahare pakeng tsa 0.70-0.80%, silicon (Si) dikahare pakeng tsa 0.10-0.35%, le manganese (Mn) dikahare pakeng tsa 0.60-0.80%.

Pakeng tsa 0.90%, likahare tsa phosphorus (P) le sebabole (S) li ka tlase ho 0.025% ka ho latellana.

CK75 spring steel e na le elasticity e ntle le ho tiea 'me hangata e sebelisoa ho etsa liliba, li-blades, li-blades tsa saw, lithipa le likarolo tse ling le lisebelisoa tse hlokang matla a phahameng le ho hanyetsa ho apara.

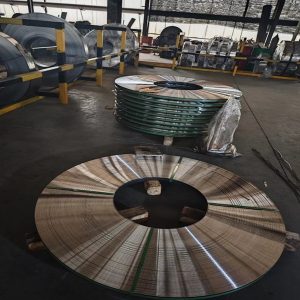

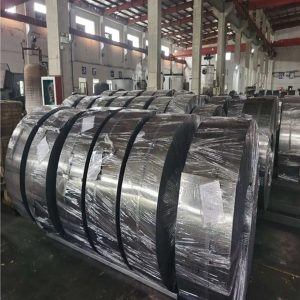

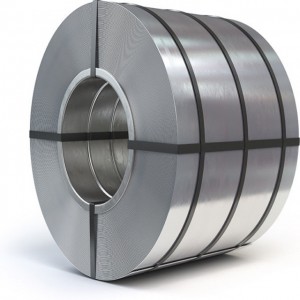

C75 C75s CK75 SAE 1075 spring steel strip

1, Maemo a thomello:

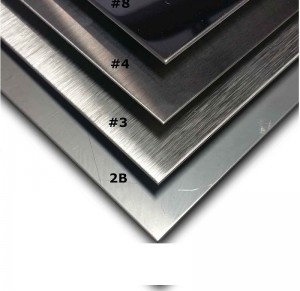

| Delivery Condition | Boholo | Bokaholimo | Qetello |

| 1.Ho bata | 1.Botenya: 0.09-8mm | E khanyang / E pholisitsoe / Blue/Yellow | Slit |

| 2.Bata O Roliloeng+Hydrogen E Annealed | 2.Bophara: 6-450mm | Ratoa | |

| 3.Mohatsela O Kotilwe+O thatafetse+Oa halefa | Coil insider diameter: 300-800mm | Sekwere |

2, papiso ea limaraka:

| MEKRETO PAPARISON BAKENG SA SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPANE JIS | JEREMANE DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | - | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL, SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Kr1 | 75Kr1 | 75Kr1 | 75Kr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3, Sebopeho sa Lik'hemik'hale:

| Standard | Kereiti | Moetso oa Lik'hemik'hale (%) | ||||||||

| C | Si | Mong | P | S | Kr | Ni | Cu | V | ||

| GB/T699 | 45 | 0.42–0,50 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47–0,55 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52–0.60 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57–0,65 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62–0,70 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67–0,75 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72–0.80 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37–0.44 | 0.17–0.37 | 0.70–1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42–0,50 | 0.17–0.37 | 0.70–1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62–0,70 | 0.17–0.37 | 0.90–1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95–1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47–0,55 | 0.17–0.37 | 0.80–1.10 | 0.035 | 0.035 | 0.90–1.20 | 0.3 | 0.3 | 0.10–0.20 |

| GB/T3077 | 50CrVA | 0.47–0,54 | 0.17–0.37 | 0.50 ~ 0.80 | 0.025 | 0.025 | 0.80–1.10 | 0.3 | 0.3 | 0.10–0.20 |

| GB/T3077 | 75Kr1 | 0.7–0.8 | 0.25–0.5 | 0.50 ~ 0.70 | 0.035 | 0.035 | 0.30–0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52–0.60 | 1.50–2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56–0,64 | 1.50–2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |