China EN10132 Standard SAE1075 batang rolled carbon steel strip CK75 C75 C75S Spring steel strip Manufacturer and Supplier | Ruiyi

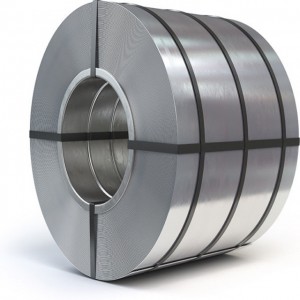

EN10132 Standard SAE1075 leqhoa le batang la tšepe le pholilengCK75C75C75S Spring steel strip e na le carbon content ea 0.7-0.8% e etsang hore e be tšepe e mengata ea carbon e nang le lisebelisoa tse ntle tsa selemo. Ka hona, ke tšepe ea carbon e sebelisoang hangata mefuteng e mengata ea likopo tsa boenjiniere.

SAE1075 kapaCK75e na le 0.7-0.8% carbon, 0.15-0.35% silicon, 0.6-0.9% manganese, le 0.03% phosphorus le sebabole. E na le matla a matla a 1230-1340 MPa, ho hlahisa matla a 1130-1240 MPa, le boima ba 57-63 HRC.

CK75 ea tšepe ea selemo e na le boima bo betere, bophara bo thata bo thata ka har'a oli bo ka fihla ho 100 ~ 150mm. CK75 kapa C75 e Lokela ho etsa liliba tse kholo haholo, joalo ka liliba tsa makhasi a bokeletsoeng holim'a li-bulldozers, liliba tse kholo tsa likhoele le liliba tse kholo tsa torsion likepeng.

CK75 spring steel ke thepa e phahameng ea carbon steel. Sebopeho sa eona sa lik'hemik'hale se kenyelletsa haholo-holo carbon (C) dikahare pakeng tsa 0.70-0.80%, silicon (Si) dikahare pakeng tsa 0.10-0.35%, le manganese (Mn) dikahare pakeng tsa 0.60-0.80%. Pakeng tsa 0.90%, likahare tsa phosphorus (P) le sebabole (S) li ka tlase ho 0.025% ka ho latellana. CK75 spring steel e na le elasticity e ntle le ho tiea 'me hangata e sebelisoa ho etsa liliba, li-blades, li-blades tsa saw, lithipa le likarolo tse ling le lisebelisoa tse hlokang matla a phahameng le ho hanyetsa ho apara.

C75 C75s CK75 SAE 1075 spring steel strip

1, Maemo a thomello:

| Delivery Condition | Boholo | Bokaholimo | Qetello |

| 1.Ho bata | 1.Botenya: 0.09-8mm | E khanyang / E pholisitsoe / Blue/Yellow | Slit |

| 2.Bata O Roliloeng+Hydrogen E Annealed | 2.Bophara: 6-450mm | Ratoa | |

| 3.Mohatsela O Kotilwe+O thatafetse+Oa halefa | Coil insider diameter: 300-800mm | Sekwere |

2, papiso ea limaraka:

| MEKRETO PAPARISON BAKENG SA SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPANE JIS | JEREMANE DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | - | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL, SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Kr1 | 75Kr1 | 75Kr1 | 75Kr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3, Sebopeho sa Lik'hemik'hale:

| Standard | Kereiti | Moetso oa Lik'hemik'hale (%) | ||||||||

| C | Si | Mong | P | S | Kr | Ni | Cu | V | ||

| GB/T699 | 45 | 0.42–0,50 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47–0,55 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52–0.60 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57–0,65 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62–0,70 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67–0,75 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72–0.80 | 0.17–0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37–0.44 | 0.17–0.37 | 0.70–1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42–0,50 | 0.17–0.37 | 0.70–1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62–0,70 | 0.17–0.37 | 0.90–1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95–1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47–0,55 | 0.17–0.37 | 0.80–1.10 | 0.035 | 0.035 | 0.90–1.20 | 0.3 | 0.3 | 0.10–0.20 |

| GB/T3077 | 50CrVA | 0.47–0,54 | 0.17–0.37 | 0.50 ~ 0.80 | 0.025 | 0.025 | 0.80–1.10 | 0.3 | 0.3 | 0.10–0.20 |

| GB/T3077 | 75Kr1 | 0.7–0.8 | 0.25–0.5 | 0.50 ~ 0.70 | 0.035 | 0.035 | 0.30–0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52–0.60 | 1.50–2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56–0,64 | 1.50–2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

4, Mamello ea rona:

| TS'OANELO MAMELLO | |||||||

| Botenya ba Lebitso (mm) | W <125 | 125 <= W | |||||

| A | B | C | A | B | C | ||

| 0,15~0,25 | TS EN | ±0,015 | ±0,012 | ±0,008 | ±0,020 | ±0,015 | ±0,010 |

| Top Tšepe | ±0,008 | ±0,010 | |||||

| 0,25~0,40 | TS EN | ±0,020 | ±0,015 | ±0,010 | ±0,025 | ±0,020 | ±0,012 |

| Top Tšepe | ±0,010 | ±0,012 | |||||

| 0,40~0,60 | TS EN | ±0,025 | ±0,020 | ±0,012 | ±0,030 | ±0,025 | ±0,015 |

| Top Tšepe | ±0,015 | ±0,015 | |||||

| 0,60~1,00 | TS EN | ±0,030 | ±0,025 | ±0,015 | ±0,035 | ±0,030 | ±0,020 |

| Top Tšepe | ±0,015 | ±0,020 | |||||

| 1,00~1,50 | TS EN | ±0,035 | ±0,030 | ±0,020 | ±0,040 | ±0,035 | ±0,025 |

| Top Tšepe | ±0,020 | ± 0,025 | |||||

| 1,50~2,50 | TS EN | ±0,040 | ±0,035 | ±0,025 | ±0,050 | ±0,040 | ±0,030 |

| Top Tšepe | ±0,025 | ±0,030 | |||||

| 2,50~4,00 | TS EN | ±0,050 | ±0,040 | ±0,030 | ±0,060 | ±0,050 | ±0,035 |

| Top Tšepe | ±0,030 | ±0,035 | |||||

| Ka kopo ikopanye le rona haeba u na le litlhoko tse khethehileng. | |||||||

| WIDTH TOLERANCES FOR SLIT EDGE (GK) | |||||||

| Width Tolerances TS EN 10140 | Bophara ba Tlhahiso (mm) | ||||||

| Botenya ba Lebitso (mm) | W <125 | 125 <= W <= 250 | 250 | ||||

| A | B | A | B | A | B | ||

| 0,2 ~ 0,6 | TS EN | ± 0,15 | ± 0,10 | ± 0,20 | ± 0,13 | ± 0,25 | ± 0,18 |

| PHAPANG TŠEPE | ± 0,10 | ± 0,13 | ± 0,18 | ||||

| 0,6 ~ 1,5 | TS EN | ± 0,20 | ± 0,13 | ± 0,25 | ± 0,18 | ± 0,30 | ± 0,20 |

| PHAPANG TŠEPE | ± 0,13 | ± 0,18 | ± 0,20 | ||||

| 1,5 ~ 2,5 | TS EN | ± 0,25 | ± 0,18 | ± 0,30 | ± 0,20 | ± 0,35 | ± 0,25 |

| PHAPANG TŠEPE | ± 0,18 | ± 0,20 | ± 0,25 | ||||

| 2,5 ~ 4,0 | TS EN | ± 0,30 | ± 0,20 | ± 0,35 | ± 0,25 | ± 0,40 | ± 0,30 |

| PHAPANG TŠEPE | ± 0,20 | ± 0,25 | ± 0,30 | ||||

5, Likopo:

| Tekanyetso ea sehlahisoa | Lisebelisoa | S50C(CK50/1050) | – Teipi e lekanyang | |

| 65Si2Mn | – Lithaba | - Likarolo tsa sebopeho sa lik'hamera | ||

| 50CrV4 | – Lithaba | - Likarolo tsa ketane | ||

| 51CrV4 | – Lithaba | – Lithaba | ||

| SK4 (1095) | – Teipi e lekanyang | - Likarolo tsa clutch | ||

| - Mehala ea lehare | – Lihlatsoa | |||

| – Lintlha tsa pene | – Polokeho buckles | |||

| – Lithaba tsa moea | S55C(CK55/1050) | – Lithaba | ||

| – Lithaba | – Lieta tsa polokeho | |||

| – Cutlery | – Na openers | |||

| – ho loha linale | - Li-blades tsa Thompson | |||

| SK5 (1085) | – Teipi e lekanyang | - Likarolo tsa sebopeho sa lik'hamera | ||

| – Likhakanyo | S60C(CK60/1060) | - Likarolo tsa ketane | ||

| – Lithaba | – Lisakha tsa letsoho bakeng sa ho betla mapolanka | |||

| – Cutlery | – Lieta tsa polokeho | |||

| – ho loha linale | – Lithaba | |||

| – Band sakha bakeng sa mapolanka | - Likarolo tsa lisebelisoa tsa ofisi | |||

| le ho rema lifate | – Lihlatsoa | |||

| – lisakha Round | S65C(65MN/CK67) | – Lieta tsa polokeho | ||

| - Likarolo tsa lisebelisoa tsa ofisi | - Likarolo tsa clutch | |||

| S45C(CK45/1045) | - Likarolo tsa clutch | – Lithaba | ||

| - Likarolo tsa ketane | – Lihlatsoa | |||

| – Baboloki | S75C(CK75/1075) | - Likarolo tsa clutch | ||

| – Lihlatsoa | – Lithaba | |||

| S50C(CK50/1050) | – Teipi e lekanyang | – Band saw | ||

| - Likarolo tsa sebopeho sa lik'hamera |