China Extruded aluminium fensetere profiles Manufacturer le Supplier | Ruiyi

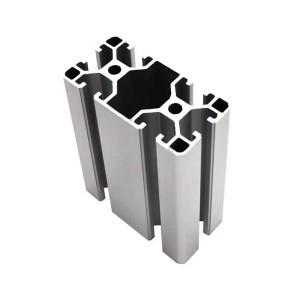

Profaele ea aluminium extrusionbakeng sa mamati le lifensetere ke mofuta oa thepa ea mokhabiso oa menyako le lifensetere tse entsoeng ka motsoako oa aluminium e le lisebelisoa tse tala. Melemo ea eona ke ho hanyetsa khatello ea moea hantle le ho se che, 'me ke thepa e tsebahalang e thibelang mollo.

Aluminium alloy mamati le lifensetere li bua ka mamati le lifensetere tse entsoeng ka aluminium alloy extruded profiles joalo ka liforeimi, li-stiles le lifens. Li bitsoa mamati a aluminium alloy le lifensetere, kapa mamati le lifensetere tsa aluminium ka bokhutšoanyane. Aluminium alloy mamati le lifensetere li kenyelletsa mamati le lifensetere tse entsoeng ka motsoako oa aluminium e le thepa ea motheo ea setho se nang le matla (setho se jereng le ho fetisetsa boima ba sona le mojaro), le lisebelisoa tsa lehong le tsa polasetiki.

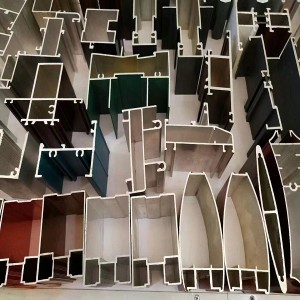

Mokhoa oa tlhahiso ea aluminium alloy monyako lelifaele tsa fenseteree kenyelletsa lits'ebetso tse tharo tse kholo: ho qhibiliha, ho bopa ha extrusion, le ho kenya mebala. Mokhoa oa ho kenya mebala o kenyelletsa likhetho tse tharo: anodic oxidation, moea oxidation, le pente ea fluorocarbon.

1. Ho qhibiliha ke mokhoa o ka sehloohong oa tlhahiso ea aluminium alloy door le lifensetere tsa lifensetere

1. Lisebelisoa tse tala, ho ea ka li-profiles tsa aluminium tsa sebele tse lokelang ho hlahisoa, li bala palo ea likarolo tse sa tšoaneng tsa motsoako oa aluminium tse kentsoeng, 'me li tsamaisane ka katleho le lisebelisoa tse sa tšoaneng tse tala;

2. Smelting: Lisebelisoa tse tala tse khethiloeng li kenngoa sebōping sa ho qhibiliha bakeng sa ho qhibiliha ho ea ka melao ea theknoloji ea ho sebetsa, 'me slag le khase e qhibilihisitsoeng e tlosoa ka mokhoa o utloahalang ho ea ka mekhoa ea ho hloekisa le ea slagging;

3. Forging: Tlas'a maemo a itseng a forging process, mokelikeli oa aluminium o qhibilihisitsoeng o ka fetoloa lithupa tse pota-potileng tsa litlhaloso tse fapaneng le mehlala ka mor'a hore metsi a pholisoe ho latela software ea tsamaiso ea metsi e tebileng ea metsi.

Extrusion molding e etsoa ka mohala oa tlhahiso ea othomathike o nang le mocheso oa ingot, extrusion, pholileng, ho otlolla tsitsipano, sawing le lits'ebetso tse ling.

Thepa e moleng oa tlhahiso e kenyelletsa sebōpi sa ho futhumatsa ka induction, mochini oa extrusion, tafole ea sebōpi, mochini o tsamaisang thepa, ho phahamisa le ho fetisa sesebelisoa, bethe e pholileng, mochini oa tsitsipano, tafole ea polokelo, terekere, mochini oa sawing, jj.

1. Sebōpi sa ho futhumatsa sa induction, mocheso o futhumatsang oa ingot o laoloa ka kakaretso ho 400 ° C ~ 520 ° C, haeba mocheso o phahame haholo kapa o le tlase haholo, o tla ama ka ho toba ho bōptjoa ha extrusion. Mochini oa extrusion ka kakaretso o nka mochini oa khatiso oa hydraulic o nang le ts'ebetso e le 'ngoe,' me tonnage ea eona e pakeng tsa lithane tse 1200 le lithane tse 2500.

2. Bophara ba cylinder ea extrusion ea mochine oa extrusion bo fapana le tonnage ea mochine oa extrusion. E kholoanyane lithane tsa mochini oa extrusion, bophara bo boholo ba cylinder ea extrusion.

Bophara ba moqomo oa extrusion ka kakaretso bo maemong a 150mm ~ 300mm. Mocheso o sebetsang oa sesebelisoa sa extrusion ke 360 ° C ~ 460 ° C, 'me lebelo la extrusion ke 20 m / min ~ 80m / min. Lisebelisoa tsa Extrusion haholo-holo li kenyelletsa ho shoa. Li-extrusion dies li arotsoe ka likarolo tse bataletseng, tse arohaneng, leleme lea shoa le li-splitter tse kopantsoeng li shoa ho ea ka litšobotsi tsa tsona tsa sebopeho. Tlhahiso ea aluminium alloy mamati le profiles ea lifensetere hangata e sebelisa lifolakha tse bataletseng le ho arohana hoa shoa.

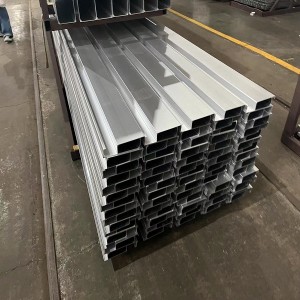

3. Tafole ea ho qhala e fumana profil e ntšitsoeng ho tsoa ho extruder mme e fetisetsa setšoantšo ho tafoleng ea ho tsoa. Boholo ba workbench ea ho lahla ke mohlala oa lipalangoang tse rapameng, 'me lebelo la motsamao oa sekhahla se otlolohileng se lumellana le lebelo la extrusion.

4. Bethe e pholileng hangata ke ea mofuta oa sefate sa ho tsamaea, 'me palo e kholo ea li-fan e kenyelelitsoe ka tlase ho etsa bonnete ba hore ho pholile ka mokhoa o ts'oanang oa profiles, e le hore mocheso oa litlaleho o fokotsehe ho feta 70 ° C pele o otloloha.

5. Mochini o otlollang tsitsipano o na le mehlahare ea torsion, e ka otlollang le ho otloloha ha ho lokisoa ha torsion. Ka mor'a boemo ba tsitsipano ke tafole ea polokelo ea thepa, e fanang ka litlaleho ho tafoleng ea mochine oa sawing, 'me mochine oa ho roala o khaola litlaleho ho ea ka bolelele bo tsitsitseng.

Kalafo ea mebala ea lemati la aluminium alloy le profiles tsa fensetere

Phekolo e kaholimo ea aluminium alloy mamati le profil ea lifensetere hangata e entsoe ka anod ho etsa hore bokaholimo ba profil bo be bosoeu. Kalafo ea holim'a metsi e ka ntlafatsa ponahalo ea profil le ho lelefatsa bophelo ba ts'ebeletso ea profil ea aluminium le lifensetere.

Ho phalla ha metsi: ho kenya → ho hloekisa → ho hlatsoa metsi → alkali etching → ho hlatsoa ka metsi a futhumetseng → ho hlatsoa metsi a batang → leseli le sa nke lehlakore → ho hlatsoa metsi → anodizing → ho hlatsoa metsi a batang → ho hlatsoa ka metsi a futhumetseng → ho tiisa → ho omisa → ho laolla → ho qeta tlhahlobo ea sehlahisoa → ho paka botenya ba filimi ea oxide ka mor'a hore ho be le oxidation ea anodic ea aluminium monyako le profiles ea fensetere ha e ka tlaase ho 10 μm.

Phekolo ea holim'a mamati a aluminium le lifensetere le eona e ka ba mebala. Lifaele tsa aluminium tse hlokang mebala e meng li ka fumanoa ka 'mala oa tlhaho oa oxidation, mebala ea electrolytic le mebala e qoelisoang.

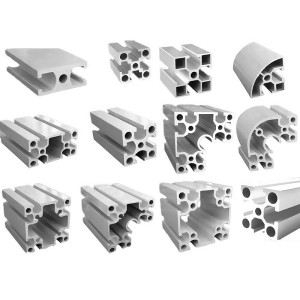

6061 6063 Aluminium profiles moetsi RAYIWELL MFG ho tloha Chaena. Aluminium profiles e ka aroloa ka 1024, 2011, 6063, 6061, 6082, 7075 le likarolo tse ling tsa alloylintlha tsa aluminium, eo lihlopha tse 6 li leng tsona tse tloaelehileng ka ho fetisisa. Phapang lipakeng tsa limaraka tse fapaneng ke hore karo-karolelano ea likarolo tse fapaneng tsa tšepe e fapane, ntle le liprofinse tse tloaelehileng tsa aluminium bakeng sa mamati le lifensetere Ho ekelletsa ho profilse ea meralo ea aluminium joalo ka letoto la 60, letoto la 70, letoto la 80, letoto la 90, le letoto la lihlooho tse lerako. , ha ho na phapang e hlakileng ea mohlala bakeng salitlaleho tsa aluminium tsa indasteri, 'me bahlahisi ba bangata ba li sebetsa ho latela litšoantšo tsa sebele tsa bareki.

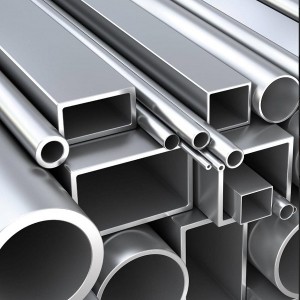

Profaele ea aluminium extrusion li hlahisoa ka ho sutumetsa li-billet tsa aluminium ka tšepe ea tšepe ho fumana libopeho tse tloaelehileng kapa tse tloaelehileng. Re ka hlahisa li-profiles tse fetisitsoeng ka boima ba mithara ho tloha ho 0.10 Kg ho isa ho 50 Kg, boholo bo boholo ba selikalikoe bo fihla ho 650mm bakeng sa lits'ebetso tsa indasteri. Ka bokhoni ba ho sebetsa ka holim'a ntlo, li-profiles tsohle tsa rona tsa aluminium li ka hlahisoa ka leloala, ka anodized kapa phofo e koahetsoeng ka mebala e lakatsehang.

Profaele ea aluminium extrusionli sebelisoa haholo lekaleng la kaho le thepa ea ka tlung, lebaleng la likoloi le indastering ea lipalangoang. Ka mohlala, re ka bolela meeli ea aluminium e nang le li-attachments tsa screw, li-drainers le li-deflectors tsa metsi, li-extrusions tse khanyang, liforeimi tsa litšoantšo, li-profiles tsa likoloi, likarolo tsa sekhutlo tse nang le likarolo tse khethehileng, li-handrails tsa aluminium.