Cina DC51D ZF Galvanized plat baja Coil Produsén jeung Supplier | Ruiyi

Hot dip galvanized pelat baja DC51D, ogé ngaranna salakulambaran baja galvanized hot dipDC51D + Z jeung hot dip séng coated plat baja jeung coil DC51D + ZF.Under Q / BQB 420 standar baja, aya DC51D + Z, DC51D + ZF nu keur bending jeung kualitas Profil, DC52D + Z, DC52 + ZF nu pikeun kualitas gambar, DC53 + Z, DC53 + ZF nu keur gambar jero kualitas, DC54D + Z, DC54D + ZF nu keur kualitas gambar jero husus, DC56D + Z, DC56D + ZF nu keur kualitas gambar jero tambahan.

DX51D nangtung pikeun lambaran baja galvanis. D kahiji hartina baja datar pikeun ngabentuk tiis. X hartina kaayaan rolling teu katangtu. 51 nyaéta nomer séri baja. D kadua hartina panas dipped galvanized.

Lamun X jadi C, nyaéta DC51D, hartina kaayaan rolling substrat tiis rolling. Bari DD51D hartina kaayaan rolling substrat téh panas rolling.

Naon deui, éta gampang ningali DX51D-Z, DX51D-ZF atanapi DX51D-AZ. The Z hartina palapis galvanized nyaeta Séng. ZF hartina palapis galvanized nyaeta Zn-Fe alloy. AZ hartina palapis galvanized nyaeta galvalume.

DX51D galvanized coils dihasilkeun nurutkeun EN 10346. The ketebalan tina palapis séng beda-beda gumantung kana sarat konsumén '.

DX51Dcoils galvanisloba dipaké pikeun produksi struktur baja, hateup, propil jandela, drainase jeung sistem ventilasi, halangan jalan, sasak, jeung panerapan rumah tangga (kasus jeung bagian internal).

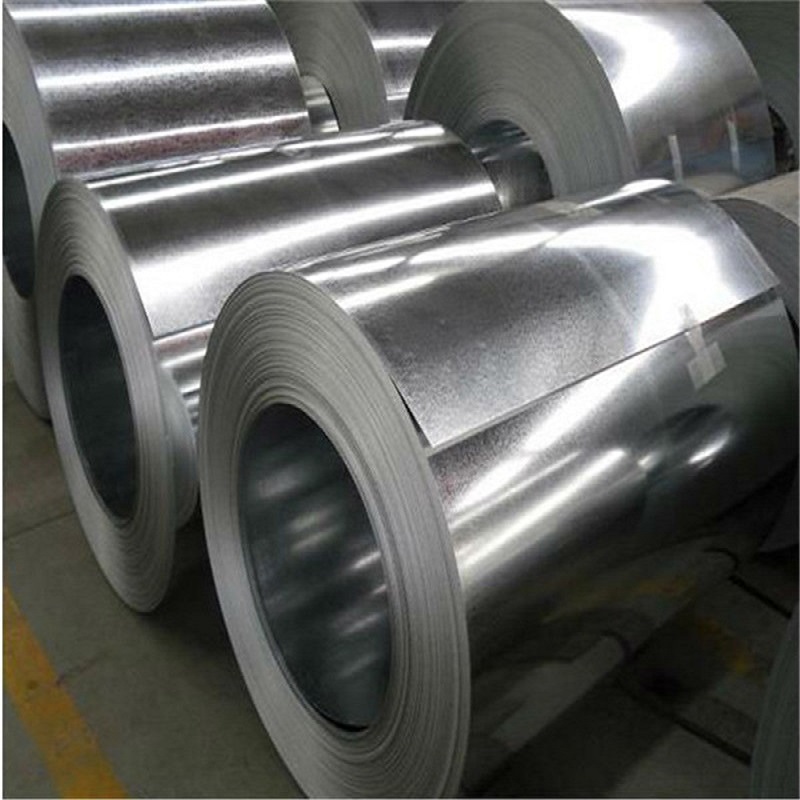

produk baja DX51D dihasilkeun dina coils 0,4-1,6 mm kandel jeung 950-1250 mm lega. Diaméter jero coil nyaéta 600 ± 20 mm sareng diaméter luar dugi ka 1300 mm. Beurat coil dugi ka 8 ton. Coils disadiakeun kalawan cut edges (giling edges oge mungkin).

Komposisi kimia sareng sipat mékanis numutkeun EN 10346

Catetan. Toleransi pikeun diménsi sareng bentuk digariskeun dina EN 10143 (toleransi pikeun lebar pikeun gulungan sahenteuna 0,7 mm kandel)

Catetan. Sarat pikeun ngabentuk sareng weldability produk réngsé kedah dipertimbangkeun nalika mesen beurat palapis séng.

Aplikasi sareng fitur dirumuskeun sapertos tabel di handap ieu

| Kelas Baja | Aplikasi | Fitur |

|---|---|---|

| DC51D+Z (St01Z, St02Z, St03Z), DC51D+ZF | Tujuan komérsial | Karbon rendah sareng / atanapi baja karbon ultra-rendah |

| DC52D+Z (St04Z), DC52D+ZF | Ngagambar | |

| DC53D+Z (St05Z), DC53D+ZF | Ngagambar jero | baja karbon ultra-low |

| DC54D+Z (St06Z), DC54D+ZF | gambar tambahan jero | |

| DD54D+Z (St06ZR) | ||

| DC56D+Z (St07Z), DC56D+ZF | Luhur tambahan gambar jero |

Komposisi Kimia%:

| bse tipe logam | Kelas | KOMPOSISI KIMIA % | |||

|---|---|---|---|---|---|

| C | Si | Bungbulang | P | ||

| lambar baja digulung tiis | DC51D+Z (St01Z, St02Z, St03Z), DC51D+ZF | ≤0.10 | – | ≤0,50 | ≤0,035 |

| DC52D+Z (St04Z), DC52D+ZF | ≤0.08 | – | ≤0.45 | ≤0,030 | |

| DC53D+Z (St05Z), DC53D+ZF | ≤0.08 | – | ≤0.40 | ≤0,030 | |

| DC54D+Z (St06Z), DC54D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0,025 | |

| DC56D+Z (St07Z), DC56D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0,025 | |

| lambaran baja digulung panas | DD51D+Z (St01ZR, St02ZR) | ≤0.10 | – | ≤0,50 | ≤0,035 |

| DD54D+Z (St06ZR) | ≤0.01 | ≤0.10 | ≤0.30 | ≤0,025 | |

| pagelaran mékanis jeung palapis adhesiveness | |||||||

|---|---|---|---|---|---|---|---|

| Kelas | pagelaran mékanis | Palapis Adhesiveness | |||||

| Ngahasilkeun Kakuatan MP | Kakuatan Tensile MP ≥ | Saatos Pegatna Persen Elongation (LO = 80mm, b = 20mm)% ≥ | Diaméter Puseur Bending dina Beurat Palapis Nuturkeun (g/m2)c (a=ketebalan pelat) | ||||

| L0 = 80mm, b = 20mm | |||||||

| Dina handap ketebalan nominal mm | ≤140/140 | > 140/140~175/175 | > 175/175 | ||||

| ≤0.7 | > 0.7 | ||||||

| DC51D+Z (St01Z, St02Z, St03Z), DC51D+ZF | – | 270~500 | 20 | 22 | 0a | 1a | 2a |

| DC52D+Z (St04Z), DC52D+ZF | 140~300 | 270~420 | 24 | 26 | |||

| DC53D+Z (St05Z), DC53D+ZF | 140~260 | 270~380 | 28 | 30 | |||

| DC54D+Z (St06Z) | 140~220 | 270~350 | 34 | 36 | |||

| DC54D+ZF | 32 | 34 | |||||

| DC56D+Z (St07Z) | 120~180 | 270~350 | 38 | 40 | |||

| DC56D+ZF | 36 | 38 | |||||

| Struktur beungeut | Kodeu No. | Fitur | Aplikasi |

|---|---|---|---|

| Spangle konvensional | Z | Spangles condensated on palapis séng dina kaayaan normal sanggeus galvanizing. | Tujuan komérsial |

| Spangle leutik | X | Permukaan dina spangles leuwih leutik batan nu konvensional sarta alatan kondensasi dikawasa tina palapis séng. | Aplikasi dimana spangles konvensional teu tiasa nyumponan sarat penampilan permukaan. |

| Kulit diliwatan spangle | G | Struktur permukaan sanggeus perlakuan pas kulit husus. | Aplikasi syarat kualitas permukaan anu luhur, sapertos pelat dasar palapis warna. |

| Kulit diliwatan spangle leutik | GX | ||

| Nol spangle | N | Henteu aya spangles anu katingali dina permukaan palapis salaku hasil tina prosés produksi khusus. | – |

| alloy Zn-Fe | R | Henteu aya spangle, kulawu, biasana matte | Lumaku pikeun lukisan salajengna |

| Perlakuan permukaan | |

|---|---|

| Perlakuan kromat (L) | Perawatan kromat mangrupikeun perlakuan kimiawi kalayan tujuan pikeun nyegah karat bodas dina permukaan produk salami transportasi sareng neundeun. |

| Minyak (Y) | Oiling nyaéta pikeun nyegah karat bodas kabentuk dina permukaan produk salami transportasi sareng neundeun. |

| Perawatan Kromat + Oiling (LY) | Perlakuan kromat + Oiling (LY) Perlakuan ieu kalayan oiling saatos perlakuan kromat permukaan nyaéta pikeun ngahindarkeun deui karat bodas. |

Kualitas permukaan

| Kode No. | Fitur |

|---|---|

| FB (O3) | t diwenangkeun pikeun ayana bintik erosi leutik, bintik poék, tanda strip, defects perlakuan kromat minor sarta partikel séng leutik. |

| FC (O4) | Taya titik erosi diwenangkeun. Sanajan kitu, eta diwenangkeun pikeun ayana kesan lampu, goresan, tanda ripple aliran séng, defects perlakuan kromat minor dina rentang leutik, sedengkeun sisi séjén kudu ngahontal syarat FB sahenteuna. |

| FD (O5) | Hiji sisi kualitas kawilang alus kudu salajengna ngawatesan on defects, nyaéta kualitas penampilan sanggeus lukisan teu kapangaruhan, sarta sisi séjén kudu ngahontal syarat FB sahenteuna. |

Daptar rujukan kelas baja tina standar, standar anu dicutat sareng standar anu sanés

| Q / BQB 420-2003 | EN10142:2000 EN10147:2000 EN10292:2000 | EN 10142:1990 EN 10147:1991 | JISG3302-1994 | ASTMA653M-2002 |

|---|---|---|---|---|

| DC51D+Z (St01Z, St02Z, St03Z), DC51D+ZF | DC51D+Z, +ZF | FeP02GZ, ZF | SGCC | CS tipe C |

| DC52D+Z (St04Z), DC52D+ZF | DC52D+Z, +ZF | FeP03GZ, ZF | SGCC | CS tipe A, tipe B |

| DC53D+Z (St05Z), DC53D+ZF | DC53D+Z, +ZF | FeP05GZ, ZF | SGCD1 | FS tipe A, tipe B |

| DC54D+Z (St06Z), DC54D+ZF | DC54D+Z, +ZF | FeP06GZ, ZF | SGCD2 | DDS |

| DC56D+Z (St07Z), DC56D+ZF | DC56D+Z, +ZF | DX56D+Z, +ZF (SEW 021) | SGCD3 | EDDS |

| Q / BQB 420 Hot-dip galvanized / alloy séng-beusi / alloy séng-magnésium coated lambar baja jeung strip | ||||

| Ngaran baja | Hot dip galvanized / substrat digulung tiis | Hot dip galvanis / substrat digulung panas | alloy beusi séng | Séng magnésium alloy |

| baja hampang atawa baja interstitial bébas | DC51D+Z | DD51D+Z | DC51D+ZF | DC51D+ZM |

| DC52D+Z | DC52D+ZF | DC52D+ZM | ||

| DC53D+Z | DC53D+ZF | DC53D+ZM | ||

| DC54D+Z | DC54D+ZF | DC54D+ZM | ||

| DC56D+Z | DC56D+ZF | DC56D+ZM | ||

| DC57D+Z | DC57D+ZF | DC57D+ZM | ||

| baja struktural karbon atawa baja alloy low | S220GD+Z | S220GD+ZF | S220GD+ZM | |

| S250GD+Z | S250GD+ZF | S250GD+ZM | ||

| S280GD+Z | S280GD+ZF | S280GD+ZM | ||

| S320GD+Z | S320GD+ZF | S320GD+ZM | ||

| S350GD+Z | S350GD+ZF | S350GD+ZM | ||

| S550GD+Z | S550GD+ZM | |||

| Interstitial bébas-kakuatan tinggi baja | HC180YD+Z | HC180YD+ZF | HC180YD+ZM | |

| HC220YD+Z | HC220YD+ZF | HC220YD+ZM | ||

| B240P1D+Z | B240P1D+ZF | B240P1D+ZM | ||

| B260LYD+Z | B260LYD+ZF | B260LYD+ZM | ||

| HC260YD+Z | HC260YD+ZF | HC260YD+ZM | ||

| Panggang baja hardened | HC180BD+Z | HC180BD+ZF | HC180BD+ZM | |

| HC220BD+Z | HC220BD+ZF | HC220BD+ZM | ||

| HC260BD+Z | HC260BD+ZF | HC260BD+ZM | ||

| HC300BD+Z | HC300BD+ZF | HC300BD+ZM | ||

| alloy low baja kakuatan tinggi | HC260LAD+Z | HC260LAD+ZF | HC260LAD+ZM | |

| HC300LAD+Z | HC300LAD+ZF | HC300LAD+ZM | ||

| HC340LAD+Z | HD340LAD+Z | HC340LAD+ZF | HC340LAD+ZM | |

| HC380LAD+Z | HC380LAD+ZF | HC380LAD+ZM | ||

| HC420LAD+Z | HD410LAD+Z | HC420LAD+ZF | HC420LAD+ZM | |

| HC460LAD+Z | HC460LAD+ZF | HC460LAD+ZM | ||

| HC500LAD+Z | HC500LAD+ZF | HC500LAD+ZM | ||

| HD550LAD+Z | ||||

| baja duplex | HC250/450DPD+Z | HC250 / 450DPD + ZF | HC250 / 450DPD + ZM | |

| HC300/500DPD+Z | HC300 / 500DPD + ZF | HC300 / 500DPD + ZM | ||

| HC280/590DPD+Z | HC280 / 590DPD + ZF | HC280 / 590DPD + ZM | ||

| HC340/590DPD+Z | HC340 / 590DPD + ZF | HC340/590DPD+ZM | ||

| B340/590DPD+Z | B340 / 590DPD + ZF | B340 / 590DPD + ZM | ||

| HC420/780DPD+Z | HC420 / 780DPD + ZF | |||

| HC500/780DPD+Z | HC500 / 780DPD + ZF | |||

| HC550/980DPD+Z | HC550/980DPD+ZF | |||

| HC650/980DPD+Z | HC650/980DPD+ZF | |||

| HC700/980DPD+Z | HC700 / 980DPD + ZF | |||

| HC740/1180DPD+Z | HC740 / 1180DPD + ZF | |||

| HC820/1180DPD+Z | HC820 / 1180DPD + ZF | |||

| baja plasticity ngainduksi transformasi | HC380/590TRD+Z | HC380/590TRD+ZF | ||

| HC400/690TRD+Z | HC400 / 690TRD + ZF | |||

| HC420/780TRD+Z | HC420 / 780TRD + ZF | |||

| baja fase kompléks | HC570/780CPD+Z | HD660/760CPD+Z | ||

| HC780/980CPD+Z | ||||

| baja ductile hardened | HC600/980QPD+Z | |||

| HC600/980QP-ELD+Z | ||||

| HC820/1180QPD+Z | ||||

| HC820/1180QP-ELD+Z | ||||