China Ck75 Steel C75s C75 SAE 1075 spring steel strip

Intsimbi ye-CK75 yintsimbi enekhabhoni ephezulu, ene-C ebonisa umthamo wekhabhoni oyi-0.75%. Ezinye izinto eziphambili ze-alloying ziquka i-manganese, i-silicon, i-phosphorus, njl.

I-CK75 Steel ineepropati kunye nezicelo zilandelayo:

Iimpawu zeCK75 Steel:

Inamandla esivuno esiphezulu kunye namandla okuqina kwaye inokumelana nemithwalo emikhulu yobunzima.

Ineempawu ezintle zoomatshini kunye neempawu zokunyanga ukushisa, kwaye ifanelekile kwimithombo yokuvelisa efuna amandla aphezulu kunye nokumelana nokunxiba.

Ubunzima bayo bunokulungelelaniswa ngonyango lobushushu ukuhlangabezana neemfuno zeemeko ezahlukeneyo zesicelo.

Inokungena kwimagnethi ethile kwaye inokusetyenziselwa ukwenza izinto ze-electromagnetic.

Inokumelana ne-corrosion elungileyo kwaye inokugcina ukugqiba kakuhle komphezulu kunye nokumelana nemozulu phantsi kweemeko ezithile.

Ukusetyenziswa kwe-CK75 Steel:

Umzi-mveliso weemoto: usetyenziselwa ukwenza imithombo ye-chassis yemoto kunye nenxalenye yenkqubo yokunqunyanyiswa.

Ukwenziwa koomatshini: kusetyenziselwa ukwenza imithombo eyahlukeneyo yoomatshini, iinxalenye zoomatshini kunye nezixhobo.

Imimandla yombane kunye nombane: isetyenziselwa ukwenza izinto ze-electromagnetic kunye nemithombo yombane.

Ulwakhiwo kunye nefenitshala: isetyenziselwa ukwenza umnyango kunye nefestile yezixhobo zentsimbi kunye nemithombo yefenitshala, njl.

Ilungele ukwenza imithombo emikhulu kakhulu, efana nemithombo yamagqabi apakishwe kwii-bulldozers, imithombo emikhulu ye-coil kunye nemithombo emikhulu ye-torsion kwiinqanawa.

I-CK75 Steel iyalingana neAISI 1075 carbon steelziquka:

I-ASTM A29 (1075)

I-ASTM A510 (1075)

I-ASTM A713 (1075)

I-SAE J403 (1075)

I-SAE J412 (1075)

EN10132 umgangatho we-SAE1075 obandayo oqengqelekayo wentsimbi yentsimbi CK75 C75 I-C75S Spring strip yentsimbi inomxholo wekhabhoni ye-0.7-0.8% eyenza i-carbon steel multi-purpose eneempawu ezintle zasentwasahlobo.

Ngoko ke, isetyenziswa ngokuqhelekileyocarbon steelkuluhlu olubanzi lwezicelo zobunjineli.

I-SAE1075 okanye i-CK75 iqulethe i-0.7-0.8% yekhabhoni, i-silicon ye-0.15-0.35%, i-0.6-0.9% ye-manganese, kunye ne-0.03% ye-phosphorus kunye ne-sulphur. Inamandla e-tensile ye-1230-1340 MPa, amandla emveliso ye-1130-1240 MPa, kunye nobunzima be-57-63 HRC.

I-CK75 yasentwasahlobo yentsimbi inokuqina okungcono, i-diameter enzima enzima kwi-oyile inokufikelela kwi-100 ~ 150mm.

I-CK75 okanye i-C75 Ifanelekile ukwenza imithombo emikhulu kakhulu, efana nemithombo yamagqabi apakishwe kwiibulldozers, imithombo emikhulu ye-coil kunye nemithombo emikhulu ye-torsion kwiinqanawa.

Intsimbi ye-CK75 yasentwasahlobo yinto enekhabhoni ephezulu. Ukwakhiwa kweekhemikhali zayo ikakhulu kubandakanya i-carbon (C) umxholo phakathi kwe-0.70-0.80%, umxholo we-silicon (Si) phakathi kwe-0.10-0.35%, kunye nomxholo we-manganese (Mn) phakathi kwe-0.60-0.80%.

Phakathi kwe-0.90%, iziqulatho ze-phosphorus (P) kunye nesulfure (S) zingaphantsi kwe-0.025% ngokulandelanayo.

Intsimbi ye-CK75 yasentwasahlobo inokwaluka okulungileyo kunye nokuqina kwaye ihlala isetyenziselwa ukwenza iziphethu, iibhleyidi, iibhleyidi zeesarha, iimela kunye nezinye iindawo kunye nezixhobo ezifuna ukomelela okuphezulu kunye nokumelana nokunxiba.

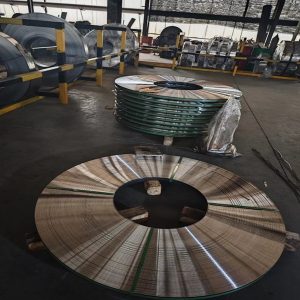

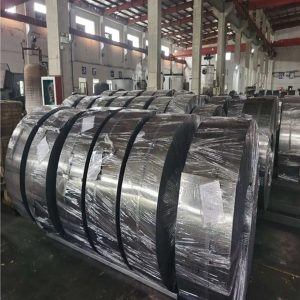

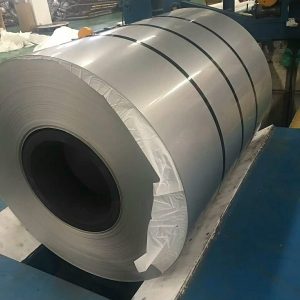

I-C75 C75s CK75 SAE 1075 intsimbi yentsimbi yasentwasahlobo

1,Imiqathango yonikezelo:

| Unikezelo Imeko | Ubukhulu | Umphezulu | Edge |

| 1.Ingqele Iqengqelekisiwe | 1.Ukutyeba: 0.09-8mm | Iqaqambile / Ikhazimliswe / Blue/Yellow | Slit |

| 2.I-Cold Rolled+Hydrogen Annealed | 2.Ububanzi: 6-450mm | Umjikelo | |

| 3.Ingqele Iqengqiwe+Iqinisiwe+Yomelele | Ikhoyili ngaphakathi diameter: 300-800mm | Isikwere |

2, uthelekiso lwaBanga:

| AMABANGA UKUTHELEKISWA KWE-SPRING STEEL | ||||||||

| TSHAYANA GB/T | E-USA ASTM | EJAPAN JIS | EJAMANI DIN | FRANCE NF | BIRTAIN BS | ISO | EKOREA KS | TAIWAN CNS |

| 45 | 1045 | S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | S50C | CK50 | XC50 | 080M50 | C50 | ||

| 60 | 1060 | S60C | CK60 | XC60 | 060A62 | C60 | ||

| 70 | 1070 | S70C | CK70 | XS70 | S70 | |||

| 75 | 1075 | S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | - | SK85 | ||||||

| 40Mn | 1043 | SWRH42B | 40Mn4 | 40M5 | 080A40 | SL,SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | I-S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | SPS5A | SUP9A | ||

| 30CrMo | G41300 | SUP13 | 35CrMo4 | SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

3,Ukwakheka kweeKhemikhali:

| Umgangatho | IBanga | Ukuqulunqwa kwemichiza (%) | ||||||||

| C | Si | Mnu | P | S | Cr | Ni | Cu | V | ||

| GB/T699 | 45 | 0.42-0.50 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 50 | 0.47-0.55 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 55 | 0.52-0.60 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 60 | 0.57-0.65 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 65 | 0.62-0.70 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 70 | 0.67-0.75 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | 75 | 0.72-0.80 | 0.17-0.37 | 0.50 ~ 0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn40 | 0.37-0.44 | 0.17-0.37 | 0.70-1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn45 | 0.42-0.50 | 0.17-0.37 | 0.70-1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T699 | Mn65 | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| GB/T1298 | SK4 | 0.95-1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| GB/T3077 | 51CrV4 | 0.47-0.55 | 0.17-0.37 | 0.80-1.10 | 0.035 | 0.035 | 0.90-1.20 | 0.3 | 0.3 | 0.10 ~ 0.20 |

| GB/T3077 | 50CrVA | 0.47-0.54 | 0.17-0.37 | 0.50 ~ 0.80 | 0.025 | 0.025 | 0.80-1.10 | 0.3 | 0.3 | 0.10 ~ 0.20 |

| GB/T3077 | 75Cr1 | 0.7-0.8 | 0.25 ~ 0.5 | 0.50 ~ 0.70 | 0.035 | 0.035 | 0.30 ~ 0.40 | |||

| GB/T1222 | 55Si2Mn | 0.52-0.60 | 1.50 ~ 2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| GB/T1222 | 60si2Mn | 0.56-0.64 | 1.50 ~ 2.00 | 0.60 ~ 0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |