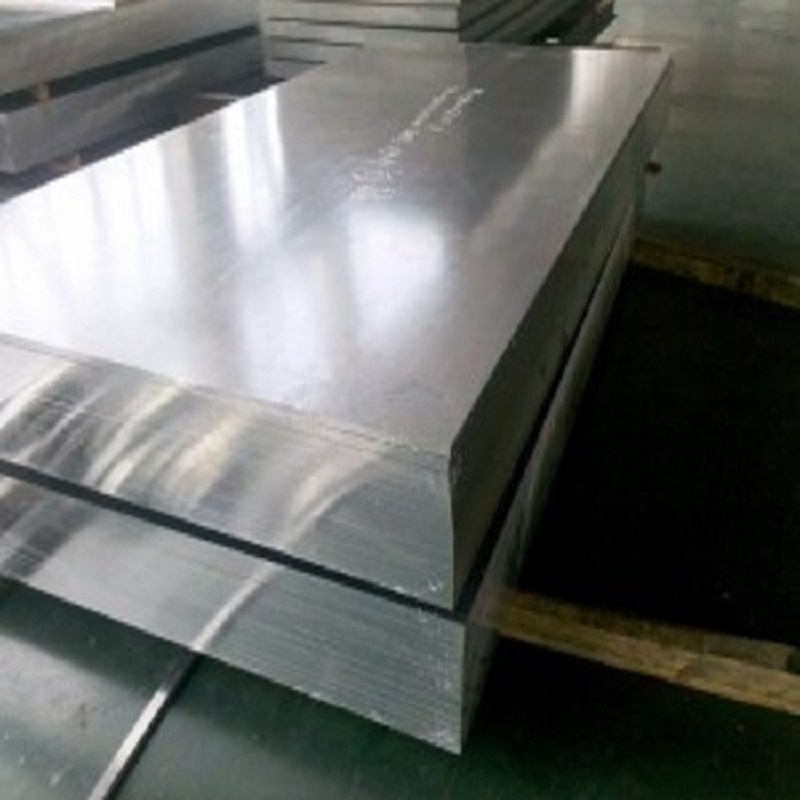

China 7475 T6 Aerospace aluminium plate sheet Umkhiqizi Nomphakeli | Ruiyi

I-7475 aluminium alloy iyingxubevange eyenziwe ngenani eliphakeme lesisindo se-zinc. Futhi iqukethe i-magnesium, i-silicon ne-chromium.

7475 ingxubevange ayikwazi ezishiselwe. Ine-spring back ngenxa yamandla ayo. Inokusebenza okuphezulu.

Ishidi le-7475 aluminium ngokuvamile linikeza ukwanda okungama-40% kokuqina uma kuqhathaniswa ne-7075 aluminium. Nakuba izici zokusebenza ze-7075 zifana, ishidi le-aluminium engu-7475 linikeza ukukhathala okuthuthukisiwe nokusebenza kokumelana nokugqwala okuqhathaniswa nokuvame ukuba ngcono kunamanye amamaki e-aluminium anamandla aphezulu. Ishidi le-7475 aluminium lilungele ukusetshenziswa lapho ukucatshangelwa kufaka phakathi amandla aphezulu emishini, ukuqina okuthuthukisiwe kokuphuka, kanye nokusakazwa kwe-crack yokukhathala kubaluleke kakhulu.

7475 Aluminium Sheet Properties

1. Inqubo eyingqayizivele yokucwenga okusanhlamvu iqinisekisa ukuthi lonke uchungechunge lwe-aviation aluminium alloy lungadlula inqubo yokuhlola i-ultrasonic. Ayinayo i-porosity, imifantu, amagwebu kanye nokungcola.

2. Ukucindezeleka kwangaphakathi: Inqubo ephelele yangaphambi kokwelula iqeda ngokuphelele ukucindezeleka kwangaphakathi, futhi ayiguquki, ayiqhekeki noma iphazamiseke ngesikhathi sokucubungula.

3. Ukunemba kokubekezelelana: Ihambisana ne-American Society for Testing and Materials (ASTM) kanye Nezicaciso Zezinto Zokusebenza Kwe-Aerospace (AMS).

4. Ukusebenza kokucubungula: Ukuchezuka kokwakheka kwamakhemikhali, amandla nobulukhuni kuyancishiswa, ngakho-ke, kunokusebenza okuhle kokucubungula.

5. Ukufana: I-RuiYi Aluminium inobuchwepheshe bokwelapha ukushisa. Lapho i-7475 aluminium sheetingaphansi kuka-300mm ukujiya, amandla nobulukhuni kungagcinwa ngokuvumelana.

6. Ukuzinza: Zonke izinqubo zokukhiqiza zilawulwa ikhompuyutha, ngokuphambuka okumbalwa kwabantu, futhi ukusebenza okufanayo kungaqinisekiswa ngamaqoqo ahlukene okukhiqiza.

7. Umphumela we-anodizing: Umphumela wayo we-anodizing ufana futhi uyacwebezela, futhi azikho izici ezingaphezulu.

8. Ukumelana nokugqwala: Inokumelana okuhle kakhulu nokugqwala kwengcindezi futhi ngeke kubangele ukubola noma kube mnyama lapho isetshenziswa isikhathi eside ngaphansi kwemithombo yezindaba ehlukahlukene (njengomhwamuko wamanzi, i-asidi ebuthakathaka ne-alkali ebuthakathaka, njll.)

9. Ukumelana nezinga lokushisa eliphezulu: Ngeke kukhiqize ukuguquguquka okuhlala njalo ngesikhathi sokusebenza ku-400 ° C.

10. Ukusebenza kokugoba: Wonke amapuleti aphumelele ukuhlolwa kokugoba kwe-semi-conductive, futhi akukho ukuqhekeka okuzokwenzeka lapho agobe ama-degree angu-180.

Ukwakheka Kwamakhemikhali

| I-ALLOY | SI | FE | CU | MN | MG | CR | ZN | ZR | TI | IZINGA |

| 7475 | 0.10 | 0.12 | 1.2-1.9 | 0.06 | 1.9-2.6 | 0.18-0.25 | 5.2-6.2 | 0.06 | 0.05 | GB/ZU/AMS |

| I-ALLOY | TEMPER | UBUDILI(MM) | WIDTH(MM) |

| 7475 | O | 0.5-4.0 | 1000-2650 |

| I-ALLOY | TEMPER | UBUDILI(MM) | AMANDLA AMANDLA(MM) I-RM(MPA) | UKUVULA AMANDLA I-RP0.2(MPA) | UKUQHUBEKA UBUDALA A50% | IZINGA |

| 7475 | O | 0.5-4.0 | 185-205 | 90-110 | 18-22 | GB/ZU/AMS |