China Ck75 Steel C75s C75 SAE 1075 spring steel strip

I-CK75 steel insimbi enekhabhoni ephezulu, eno-C ekhombisa okuqukethwe kwekhabhoni okungu-0.75%. Ezinye izakhi eziyinhloko ze-alloying zihlanganisa i-manganese, i-silicon, i-phosphorus, njll.

I-CK75 Steel inalezi zakhiwo nezindlela zokusebenza ezilandelayo:

Isici se-CK75 Steel:

Inamandla okukhiqiza aphezulu namandla aqinile futhi ingakwazi ukumelana nemithwalo emikhulu yokudonsa.

Inezici ezinhle zemishini kanye nezakhiwo zokwelashwa kokushisa, futhi ifanele ukukhiqiza iziphethu ezidinga amandla aphezulu nokumelana nokugqoka.

Ubulukhuni bayo bungalungiswa ngokwelashwa kokushisa ukuze kuhlangatshezwane nezidingo zezimo zohlelo lokusebenza ezahlukene.

Inokungena kukazibuthe okuthile futhi ingasetshenziswa ukwenza izingxenye ze-electromagnetic.

Inokumelana nokugqwala okuhle futhi ingagcina isiphetho esihle sendawo kanye nokumelana nesimo sezulu ngaphansi kwezimo ezithile.

Ukusetshenziswa kwe-CK75 Steel:

Imboni yezimoto: isetshenziselwa ukwenza iziphethu ze-chassis yezimoto nezingxenye zesistimu yokumiswa.

Ukukhiqizwa kwemishini: isetshenziselwa ukwenza iziphethu zemishini ehlukahlukene, izingxenye zemishini namathuluzi.

Izinkambu ze-elekthronikhi nezikagesi: ezisetshenziselwa ukwenza izingxenye ze-electromagnetic kanye neziphethu ezisebenzayo.

Ukwakhiwa kanye nefenisha: esetshenziselwa ukukhiqiza izesekeli ze-hardware yeminyango namafasitela neziphethu zefenisha, njll.

Ifanele ukwenza iziphethu ezinkulu kakhulu, njengeziphethu zamaqabunga anqwabelene kuma-bulldozer, imithombo emikhulu yamakhoyili kanye nemithombo emikhulu ye-torsion emikhunjini.

I-CK75 Steel iyalingana neI-AISI 1075 carbon steelzihlanganisa:

I-ASTM A29 (1075)

I-ASTM A510 (1075)

I-ASTM A713 (1075)

I-SAE J403 (1075)

I-SAE J412 (1075)

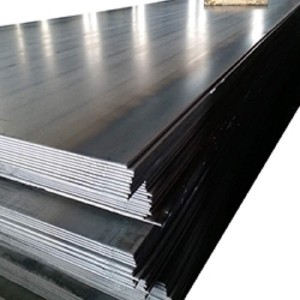

I-EN 10132 Standard SAE1075 umugqa wensimbi obandayo ogoqeke wekhabhoni CK75 C75 I-C75S Spring steel strip inokuqukethwe kwekhabhoni okungu-0.7-0.8% okwenza kube insimbi ye-carbon enezinjongo eziningi enezakhiwo ezinhle zasentwasahlobo.

Ngakho-ke, isetshenziswa ngokuvamileinsimbi ye-carbonezinhlobonhlobo zezicelo zobunjiniyela.

I-SAE1075 noma i-CK75 iqukethe u-0.7-0.8% wekhabhoni, u-0.15-0.35% we-silicon, u-0.6-0.9% we-manganese, kanye no-0.03% we-phosphorus nesibabule. Inamandla okuqina angu-1230-1340 MPa, ikhiqiza amandla angu-1130-1240 MPa, kanye nokuqina kwe-57-63 HRC.

I-CK75 spring steel inokuqina okungcono, ububanzi obuqinile obuqinile emafutheni bungafinyelela ku-100 ~ 150mm.

I-CK75 noma i-C75 Ifanele ukwenza iziphethu ezinkulu kakhulu, njengeziphethu zamaqabunga anqwabelene kuma-bulldozer, imithombo emikhulu yamakhoyili kanye neziphethu ze-torsion ezinkulu emikhunjini.

I-CK75 spring steel impahla yensimbi enekhabhoni ephezulu. Ukwakheka kwamakhemikhali ayo ikakhulukazi kuhlanganisa okuqukethwe kwekhabhoni (C) phakathi kuka-0.70-0.80%, okuqukethwe kwe-silicon (Si) phakathi kuka-0.10-0.35%, nokuqukethwe kwe-manganese (Mn) phakathi kuka-0.60-0.80%.

Phakathi kuka-0.90%, okuqukethwe kwe-phosphorus (P) kanye nesulfure (S) kungaphansi kuka-0.025% ngokulandelanayo.

I-CK75 spring steel inokunwebeka okuhle kanye nokuqina futhi ivame ukusetshenziselwa ukwenza iziphethu, ama-blades, ama-saha izindwani, imimese nezinye izingxenye namathuluzi adinga amandla aphezulu kanye nokumelana nokuguga.

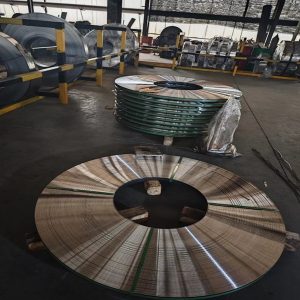

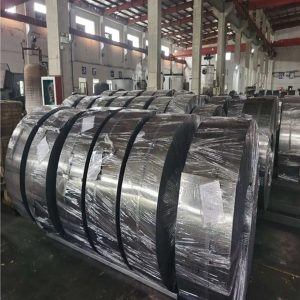

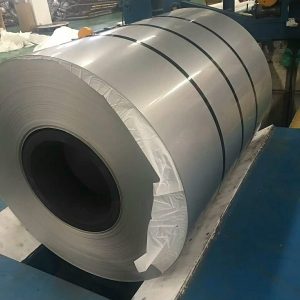

I-C75 C75s CK75 SAE 1075 i-spring steel strip

1, Izimo Zokulethwa:

| Isimo sokulethwa | Osayizi | Ubuso | Umphetho |

| 1.Ukubanda Kugoqekile | 1.Ubukhulu: 0.09-8mm | Kuyakhanya / Kupholishwe / Blue/Yellow | I-Slit |

| 2.I-Cold Rolled+Hydrogen Annealed | 2.Ububanzi: 6-450mm | Umjikelezo | |

| 3.Kugodole Kugoqekile+Kuqinile+Kuqinile | Ikhoyili ububanzi bangaphakathi: 300-800mm | Isikwele |

2, ukuqhathanisa Amabanga:

| AMABANGA OKUQHATHANISWA WEZINTAMBI Spring | ||||||||

| I-CHINA GB/T | USA ASTM | EJAPANE JIS | EJALIMANE DIN | I-FRANCE NF | I-BIRTAIN BS | ISO | I-KOREA KS | I-TAIWAN CNS |

| 45 | 1045 | I-S45C | CK45 | XC45 | C45 | |||

| 50 | 1050 | I-S50C | CK50 | I-XC50 | 080M50 | C50 | ||

| 60 | 1060 | I-S60C | CK60 | I-XC60 | 060A62 | C60 | ||

| 70 | 1070 | I-S70C | CK70 | I-XS70 | S70 | |||

| 75 | 1075 | I-S75C | CK75 | XC75 | C75 | |||

| T10 | W1-9 | SK4 | ||||||

| T9 | W1-8 | SK5 | ||||||

| SK85 | - | SK85 | ||||||

| 40Mn | 1043 | I-SWRH42B | 40 mn4 | 40M5 | 080A40 | SL,SM | ||

| 42Mn | ||||||||

| 65Mn | 1566 | I-S60C-CSP | CK67 | 080A67 | I-C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 /SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 60Si2Mn | 9260 | SUP 6 / SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 62Si2Mn | ||||||||

| 75Cr1 | 75Cr1 | 75Cr1 | 75Cr1 | |||||

| 51CrV4 | 5160 | SUP9A | 51CrV4 | 51CrV4 | I-SPS5A | SUP9A | ||

| 30CrMo | I-G41300 | SUP13 | 35CrMo4 | I-SPS9 | SUP13 | |||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | I-SPS6 | SUP10 |

3,Ukwakheka Kwekhemikhali:

| Okujwayelekile | Ibanga | Ukwakhiwa Kwekhemikhali (%) | ||||||||

| C | Si | UMn | P | S | Cr | Ni | Cu | V | ||

| I-GB/T699 | 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T699 | 50 | 0.47-0.55 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T699 | 55 | 0.52-0.60 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T699 | 60 | 0.57-0.65 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T699 | 65 | 0.62-0.70 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T699 | 70 | 0.67-0.75 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T699 | 75 | 0.72-0.80 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T699 | Mn40 | 0.37-0.44 | 0.17-0.37 | 0.70-1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T699 | Mn45 | 0.42-0.50 | 0.17-0.37 | 0.70-1.00 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T699 | Mn65 | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | 0.035 | 0.035 | 0.25 | 0.3 | 0.25 | |

| I-GB/T1298 | SK85/SK5 | 0.80 ~0.90 | ≤0.35 | ≤0.50 | 0.03 | 0.03 | 0.2 | 0.25 | 0.3 | |

| I-GB/T1298 | SK4 | 0.95-1.04 | ≤0.35 | ≤0.40 | 0.035 | 0.03 | 0.25 | 0.2 | 0.3 | |

| I-GB/T3077 | 51CrV4 | 0.47-0.55 | 0.17-0.37 | 0.80-1.10 | 0.035 | 0.035 | 0.90-1.20 | 0.3 | 0.3 | 0.10-0.20 |

| I-GB/T3077 | 50CrVA | 0.47-0.54 | 0.17-0.37 | 0.50-0.80 | 0.025 | 0.025 | 0.80-1.10 | 0.3 | 0.3 | 0.10-0.20 |

| I-GB/T3077 | 75Cr1 | 0.7-0.8 | 0.25-0.5 | 0.50-0.70 | 0.035 | 0.035 | 0.30-0.40 | |||

| I-GB/T1222 | 55Si2Mn | 0.52-0.60 | 1.50-2.00 | 0.60-0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |

| I-GB/T1222 | 60si2Mn | 0.56-0.64 | 1.50-2.00 | 0.60-0.90 | ≤0.035 | ≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 | |