China Amafasitela e-aluminium Extruded amaphrofayili Umkhiqizi Nomhlinzeki | Ruiyi

Iphrofayili ye-aluminium extrusioniminyango namafasitela kuwuhlobo lomnyango kanye nefasitela uhlaka umhlobiso impahla zokwakha ezenziwe aluminium ingxubevange njengoba impahla eluhlaza. Izinzuzo zayo ukumelana nokucindezela komoya okuhle nokungashi, futhi iyinto eyaziwayo ekwazi ukumelana nelangabi.

Iminyango namafasitela e-aluminium alloy abhekisela eminyango namafasitela enziwe ngamaphrofayili e-aluminium alloy extruded njengamafreyimu, ama-stiles, nabalandeli. Zibizwa nge-aluminium alloy doors namafasitela, noma izicabha namafasitela e-aluminium ngamafuphi. Iminyango namafasitela e-aluminium alloy ahlanganisa iminyango namafasitela enziwe nge-aluminium alloy njengento eyisisekelo yelungu elithwala amandla (ilungu elithwala futhi lidlulisele isisindo salo kanye nomthwalo), kanye nezinhlanganisela zokhuni nepulasitiki.

Inqubo yokukhiqiza yomnyango we-aluminium alloy kanyeamaphrofayili ewindikuhlanganisa izinqubo ezintathu ezinkulu: ukuncibilika, ukubumba i-extrusion, kanye nombala. Inqubo yokwenza imibala ihlanganisa izinketho ezintathu: i-anodic oxidation, i-air oxidation, nomdwebo we-fluorocarbon.

1. Ukuncibilika kuyinqubo eyinhloko ekukhiqizeni amaphrofayili eminyango ye-aluminium alloy namafasitela

1. Izinto zokusetshenziswa, ngokusho kwamaphrofayili e-aluminium alloy angempela adinga ukukhiqizwa, ukubala inani lezingxenye ezihlukahlukene ze-aluminium alloy ezengezwe, futhi zifanise ngokuphumelelayo izinto ezihlukahlukene zokusetshenziswa;

2. Ukuncibilika: Izinto zokusetshenziswa ezikhethiwe zengezwa esithandweni sokuncibilika ukuze zincibilike ngokuvumelana nemithethonqubo yobuchwepheshe bokucubungula, futhi i-slag negesi ekuncibilikeni kususwa ngokufanele ngokuvumelana nezindlela zokuhlanza i-degassing kanye ne-slagging;

3. Ukufoja: Ngaphansi kwamazinga athile enqubo yokubumba, uketshezi lwe-aluminium oluncibilikisiwe lungaguqulwa lube izinti eziyindilinga zokuphonswa kwemininingwane namamodeli ahlukahlukene ngemva kokupholisa amanzi ngokuya ngesofthiwe yohlelo lokubumba umthombo wamanzi ajulile.

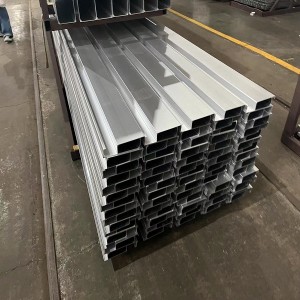

Ukubunjwa kwe-Extrusion kwenziwa emgqeni wokukhiqiza othomathikhi ohlanganisa ukushisa kwe-ingot, i-extrusion, ukupholisa, ukuqondisa ukucindezeleka, ukusika nezinye izinqubo.

Imishini ekulayini wokukhiqiza ihlanganisa isithando sokushisa sokungenisa induction, umshini wokukhipha umlilo, itafula lesithando somlilo, umshini wokuthulula, ukuphakamisa iphrofayili nokudlulisa idivayisi, umbhede wokupholisa, isileveli sokuqina, itafula lokugcina, ugandaganda, umshini wokusaha, njll.

1. Isithando sokushisa sokungeniswa, izinga lokushisa lokushisa kwe-ingot ngokuvamile lilawulwa ku-400 ° C ~ 520 ° C, uma izinga lokushisa liphezulu kakhulu noma liphansi kakhulu, lizothinta ngokuqondile ukubunjwa kwe-extrusion. Umshini we-extrusion ngokuvamile usebenzisa umshini wokucindezela we-hydraulic one-action eyodwa, futhi ithoni yawo iphakathi kwamathani ayi-1200 namathani angama-2500.

2. Ububanzi besilinda se-extrusion yomshini we-extrusion buyahlukahluka ngethoni yomshini we-extrusion. Uma umkhulu amathoni omshini wokukhipha i-extrusion, ubukhulu besilinda se-extrusion bukhulu.

Ububanzi besilinda sokukhipha ngokuvamile buphakathi kuka-150mm ~ 300mm. Izinga lokushisa elisebenzayo lethuluzi le-extrusion lingu-360 ° C ~ 460 ° C, futhi isivinini sokukhipha singama-20 m/min~80m/min. Amathuluzi e-Extrusion ikakhulukazi ahlanganisa ukufa. I-Extrusion dies ihlukaniswe yaba ama-flat dies, i-split dies, ulimi luyafa kanye ne-splitter ehlanganisiwe iyafa ngokuvumelana nezici zabo zesakhiwo. Ukukhiqizwa komnyango we-aluminium alloy namaphrofayili efasitela ngokuvamile kusebenzisa ama-flat dies kanye nokuhlukaniswa kwe-split dies.

3. Ithebula lokukhipha lithola iphrofayili ekhishwe ku-extruder futhi idlulisela iphrofayili etafuleni lokukhipha. Iningi lebhentshi lokukhipha umsebenzi liyimodeli yokuthutha evundlile, futhi isivinini sokunyakaza somugqa ovundlile sivunyelaniswa nesivinini sokukhipha.

4. Umbhede wokupholisa ungowohlobo lwe-beam ehambayo, futhi inombolo enkulu yabalandeli ifakwe ngezansi ukuze kuqinisekiswe ukupholisa okufanayo kwamaphrofayili, ukuze izinga lokushisa lamaphrofayili libe ngaphansi kuka-70 ° C ngaphambi kokuqondisa.

5. Umshini wokuqondisa ukucindezeleka ufakwe imihlathi ye-torsion, engakwazi ukwelula futhi iqondise ngenkathi ukulungiswa kwe-torsion. Ngemuva kokuthi i-tension leveler yitafula lokugcina impahla, elihlinzeka ngamaphrofayili etafuleni lomshini wokusaha, futhi umshini wokusaha usika amaphrofayili ngokuya ngobude obunqunyiwe.

Ukwelashwa kombala komnyango we-aluminium alloy namaphrofayili wefasitela

Ukwelashwa okungaphezulu komnyango we-aluminium alloy namaphrofayili efasitela kugcotshwa kakhulu ukwenza ingaphezulu lamaphrofayili libe mhlophe. Ukwelashwa okungaphezulu kungathuthukisa ukubukeka kwephrofayela futhi kunwebe impilo yesevisi yomnyango we-aluminium namaphrofayili ewindi.

Ukugeleza kwenqubo ye-anodizing: ukulayisha→ukukhipha amafutha→ukugeza amanzi→ukuhlanganisa i-alkali→ukugeza amanzi afudumele→ukugeza amanzi abandayo→ukukhanya okungathathi hlangothi→ukugeza amanzi→i-anodizing→ukugeza amanzi abandayo→ukugeza amanzi afudumele→ukuvala→ukomisa→ukukhipha→ukuhlolwa komkhiqizo okuqediwe→ukupakisha ukujiya kwefilimu ye-oxide ngemva kwe-anodic oxidation yomnyango we-aluminium namaphrofayela wefasitela abukho ngaphansi kuka-10 μm.

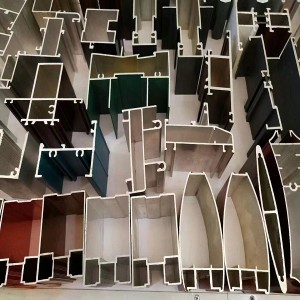

Ukwelashwa okungaphezulu komnyango we-aluminium kanye namaphrofayili wefasitela kungabuye kube nombala. Amaphrofayili e-aluminium adinga eminye imibala angatholwa ngombala wemvelo we-oxidation, umbala we-electrolytic kanye nombala wokucwilisa.

6061 6063 Amaphrofayili e-aluminium umkhiqizi i-RAYIWELL MFG evela e-China. Amaphrofayela e-Aluminium angahlukaniswa abe ngu-1024, 2011, 6063, 6061, 6082, 7075 namanye amabanga we-alloyamaphrofayili e-aluminium, okuyi-6 uchungechunge oluvame kakhulu. Umehluko phakathi kwamamaki ahlukene ukuthi isilinganiso sezingxenye ezihlukahlukene zensimbi sihlukile, ngaphandle kwamaphrofayli e-aluminium avame ukusetshenziswa eminyango namafasitela Ngaphezu kwamaphrofayili e-aluminium yezakhiwo ezifana nochungechunge lwama-60, uchungechunge lwama-70, uchungechunge lwama-80, uchungechunge lwama-90, nochungechunge lwamakhethini odonga. , awukho umehluko ocacile wemodeliamaphrofayili e-aluminium yezimboni, futhi iningi labakhiqizi lizicubungula ngokusho kwemidwebo yangempela yamakhasimende.

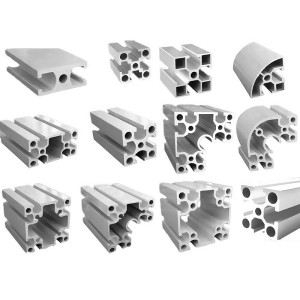

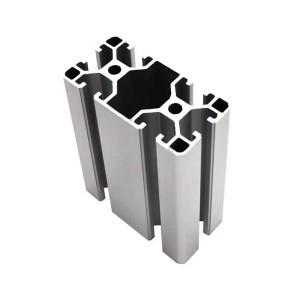

Iphrofayili ye-aluminium extrusion akhiqizwa ngokuphusha amabhilidi e-aluminium ngokusebenzisa insimbi ukuze athole izimo ezijwayelekile noma ezenziwe ngokwezifiso. Singakwazi ukukhiqiza amaphrofayli akhishiwe anesisindo imitha ngalinye ukusuka ku-0.10 Kg kuya ku-50 Kg, usayizi omkhulu wendingilizi ufika ku-650mm wezinhlelo zokusebenza zezimboni. Ngamandla okucubungula angaphakathi endlini, wonke amaphrofayili ethu e-aluminium angakhiqizwa emshinini wokugaya, afakwe i-anodized noma afakwe ngempushana ngemibala esiyifunayo.

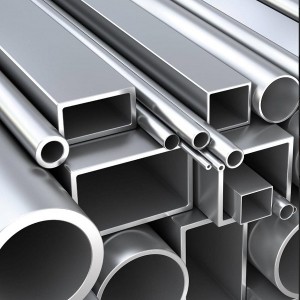

Iphrofayili ye-aluminium extrusionzisetshenziswa kakhulu emkhakheni wezokwakha kanye nefenisha, emkhakheni wezimoto kanye nasembonini yezokuthutha. Ngokwesibonelo, singabala imingcele ye-aluminium enezikulufu ezinamathiselwe ngezikulufu, ama-drainer nama-deflectors amanzi, ama-glazing extrusions, amafreyimu ezithombe, amaphrofayili wokusika wezimoto, izakhi zamakhona anezingxenye ezikhethekile, izibambo ze-aluminium nama-handrails.