I-China Eshisayo Ecwiliswe Ngensimbi Yensimbi Umkhiqizi Wokugaya

I-steel grating ngokuvamile yenziwa nge-carbon steel noma insimbi engagqwali, enikeza amandla aphezulu nokumelana nokugqwala. I-grating itholakala ngamaphethini ahlukahlukene, njenge-bar grating, i-grating yensimbi enwetshiwe, ne-grating yensimbi enembobo, ukuze ivumelane nezinhlelo zokusebenza ezahlukene kanye nezidingo zokulayisha.

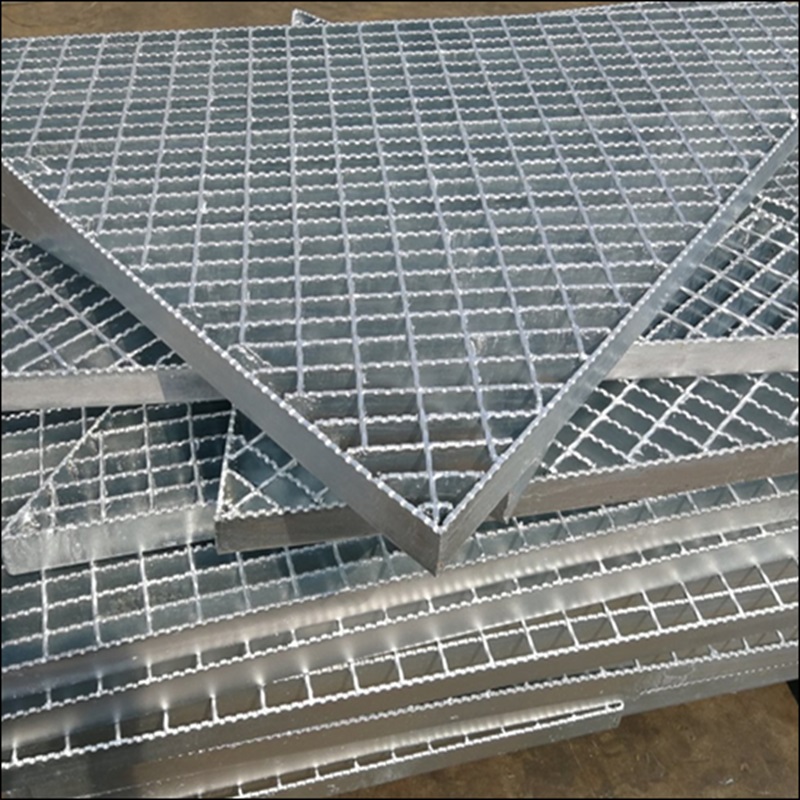

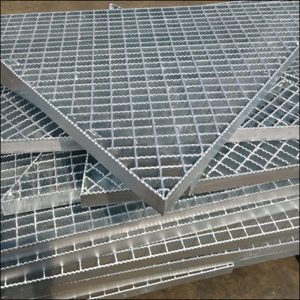

Igridi yama-hot-dip galvanized, eyaziwa nangokuthi i-hot-dipi-galvanized steel grating, into yokwakha emise okwegridi eyenziwe ngensimbi ephansi ye-carbon steel flat kanye nensimbi eyisikwele esontekile eshiselwe ngokuvundlile nangokuqondile.

Inqubo yokukhiqiza ye-Galvanized Steel Grating

Ukusika impahla eluhlaza:

I-hot-dip galvanized steel plate isikwa ngokuvumelana nezidingo zemidwebo yokwakha. Indlela yokusika ingaba i-CNC plasma cutting noma i-laser cutting. Ngemuva kokuqedwa kokusika, i-grating yensimbi idinga ukusikwa.

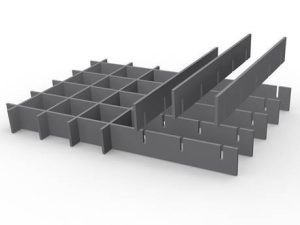

Steel grating pressure welding:

Amapuleti ensimbi asikiwe ahlanganiswa abe yigridi yomkhiqizo wensimbi emise okwegridi kusetshenziswa inqubo yokushisela ingcindezi.

Kusetshenziswa amathani angama-200 wemishini yokushisela ukumelana ne-hydraulic resistance, insimbi ethwala imithwalo eyisicaba kanye nemigoqo ephambanayo ihlelwa futhi ishiselwe ebangeni elithile epuleti lokuqala, bese icutshungulwa ngokusika, ukubhoboza, ukugoqa nezinye izinqubo ukuze kwakhiwe umkhiqizo odingwa ikhasimende.

Phakathi kwazo, ibanga eliphakathi kwensimbi eyisicaba ethwala imithwalo ngokuvamile lingama-30MM no-40MM, kanti ibanga eliphakathi kwama-crossbar ngokuvamile lingama-50MM no-100MM, kodwa futhi lingakhiqizwa ngokuvumelana nezidingo zamakhasimende.

Ukwelashwa okungaphezulu: Imikhiqizo yegriza yensimbi ngemva kokushiselwa kwengcindezi iyakhethwa ukuze kususwe ukungcola, amabala kawoyela, njll. ngaphezulu ukuze kulungiselelwe inqubo yakamuva yokufaka amadiphu ashisayo.

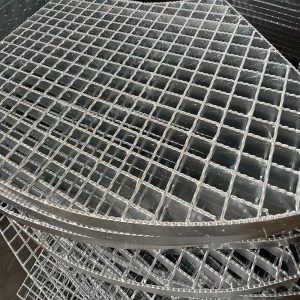

I-Hot-dip galvanizing:

Imikhiqizo ye-grating yensimbi efakwe emanzini anosawoti ashisayo-idiphu ifakwe ama-galvanized endaweni enezinga lokushisa eliphezulu. Inhloso eyinhloko ukukhiqiza ungqimba lwama-galvanized ebusweni bomkhiqizo wokugaya insimbi. Lesi singqimba esinothayela singavimbela igridi yensimbi Umkhiqizo ugqwalile ngesikhathi sokusetshenziswa.

Igridi yensimbi iwuhlobo lwegridi eyenziwe ngezinsimbi zensimbi noma amashidi ahlanganiswa ndawonye ukuze akhe isakhiwo esifana negridi. Ivamise ukusetshenziswa ezindaweni zezimboni, njengezimboni, izindawo zokugcina izimpahla, nezindawo ezingaphandle, ngenxa yamandla ayo, ukuqina, namandla okumelana nemithwalo esindayo.

Okunye ukusetshenziswa okuvamile kwe-steel grating kufaka:

1. Izindlela zokuhamba nezinkundla: Igridi yensimbi ivamise ukusetshenziselwa ukwakha izindlela zokuhamba eziphephile nezivikelekile kanye nezinkundla kuzilungiselelo zezimboni. Ihlinzeka indawo engasheleli futhi ivumela ukugeleza koketshezi kanye nemfucumfucu.

2. Izitebhisi: I-steel grating ingasetshenziswa njengezitebhisi ukunikeza izinyathelo eziphephile neziqinile ezakhiweni zezimboni nezentengiso.

3. Izembozo zokudonsa amanzi: Igridi yensimbi ivame ukusetshenziswa njengezembozo zamapayipi kanye nemigodi. Ivumela ukugeleza kwamanzi futhi ivimbele imfucumfucu ukuthi ingangeni ohlelweni lokudonsa amanzi.

4. Uthango nezithiyo: Igridi yensimbi ingasetshenziswa njengothango noma izithiyo ezindaweni ezingaphandle ukuze kuhlinzekwe ukuvikeleka nokuvimbela ukungena okungagunyaziwe.

5. Amashelufu nama-rack okugcina: Igridi yensimbi ingasetshenziswa njengamashalofu noma izigcawu zokugcina impahla ezindaweni zokugcina izimpahla nasemafekthri. Inikeza indawo eqinile futhi eqinile yokugcina izinto ezinzima.

Sekukonke, i-steel grating iyinto eguquguqukayo nethembekile esetshenziswa kakhulu ezimbonini ezahlukahlukene ngenxa yamandla ayo, ukuqina, nokusebenza kwayo.

7 Izizathu EzenzaI-Galvanized Steel GratingIlungele Ukusetshenziswa Kwangaphandle

1. Ukuqina:I-galvanized steel grating yenziwe ngensimbi e-hot-dip galvanized, ehlinzeka ngokumelana nokugqwala okuhle kakhulu futhi iqinisekisa ukuqina okuhlala isikhathi eside. Ingakwazi ukumelana nezimo ezinzima zangaphandle, okuhlanganisa ukuchayeka emvuleni, eqhweni, emingeni yelanga namakhemikhali.

2. Amandla:I-galvanized steel grating yaziwa ngezinga layo eliphezulu lamandla nesisindo. Ingakwazi ukusekela imithwalo esindayo ngaphandle kokugoba noma ukuphuka, iyenze ilungele izinhlelo zokusebenza zangaphandle lapho amandla ebaluleke kakhulu, njengezindlela zokuhamba, amapulatifomu, kanye nephansi lemboni.

3. I-Slip Resistance: Ingaphezulu legrithi yensimbi ethathiwe ngokuvamile i-serrated noma i-anti-slip, ihlinzeka ngokudonsa okuhle kakhulu ngisho nasezimeni ezimanzi noma ezishelelayo. Lokhu kukwenza kube ukukhetha okuphephile ezindaweni ezingaphandle ezithambekele ekubeni nomswakama, njengamarampu, izitebhisi, namakhava okukhipha amanzi.

4. Ukunakekela Okulula:I-galvanized steel grating idinga ukulungiswa okuncane. Indawo yayo ebushelelezi ivumela ukuhlanzwa kalula, futhi ukufakwa kukathayela kunikeza isivikelo ekugqwaleni nokugqwala, kunciphisa isidingo sokulungiswa njalo noma ukushintshwa.

5. Ingabizi:I-galvanized steel grating iyisisombululo esingabizi kakhulu sezinhlelo zokusebenza zangaphandle. Ukuphila kwayo okude kanye nezidingo zokunakekelwa okuphansi zihumushela izindleko ezincishisiwe ngokuhamba kwesikhathi. Ukwengeza, amandla ayo avumela ukusetshenziswa kwezinto ezincane, okuqhubeka nokunciphisa izindleko ngaphandle kokuyekethisa ukusebenza.

6. Ukuhlukahluka:I-galvanized steel grating ingenziwa ngezifiso ukuze ihlangabezane nezidingo ezithile zokuklama. Itholakala ngosayizi abahlukahlukene, izimo, kanye nokucushwa, okuvumela ukuguquguquka kwamaphrojekthi angaphandle. Inganqunywa kalula noma ihlanganiswe ukuze ilingane nobukhulu obuhlukahlukene, iyenze ifanele uhla olubanzi lwezinhlelo zokusebenza.

7. Ubungane bemvelo:I-galvanized steel grating iyisinqumo esimeme sokusetshenziswa ngaphandle. Inqubo yokufaka ama-galvanizing ihilela ukumboza insimbi ngongqimba lwe-zinc, okuwumsebenzi ongasetshenziswa kabusha. Ukwengeza, ukuqina kwe-galvanized steel grating kunciphisa isidingo sokushintshwa njalo, kunciphisa imfucuza kanye nomthelela emvelweni.

| Ukucaciswa | Incazelo |

|---|---|

| Okubalulekile | ASTM A36, GB Q235, S235JR, ASTM A572-50, GB Q345B, S355JR |

| Inqubo Yokukhiqiza | Ishiselwe, ikhiyiwe-swage, noma ivaliwe ngokucindezela |

| Ukwelashwa Okungaphezulu | Idiphu elishisayo lifakwe amathini |

| Uhlobo Lobuso | Indawo evamile engenalutho, indawo emise okwezinsalela |

| Isikhala Sebha Yesiphambano | Ukwenziwa ngendlela oyifisayo, ngokuvamile okungu-2″ noma 4″, phakathi nendawo |

| I-Bearing Bar Isikhala | Yenza ngokwezifiso, ngokuvamile 15/16″ noma 1-3/16″, phakathi nendawo |

| Ukuthwala Ukuphakama Kwebha | Ukwenziwa ngokwezifiso, ngokuvamile kusuka ku-20mm kuya ku-60mm |

| Ukuthwala Ukuqina Kwebha | Ukwenziwa ngokwezifiso, ngokuvamile kusuka ku-2mm kuya ku-5mm |

| Usayizi Webha Yesiphambano | Ukwenziwa ngokwezifiso, ngokuvamile kusuka ku-4mm kuya ku-10mm ububanzi |

| Slip Resistance | Indawo egobile noma engenalutho, kuye ngohlelo lokusebenza |

| Indlela Yokufaka | Ukushisela, iziqeshana, noma amabhawodi namantongomane, kuya ngohlelo lokusebenza |

| Ukuhambisana | Ihlangabezana namazinga omkhakha namakhodi okwakha asebenzayo, afaka i-ASTM, i-ISO, ne-ANSI/NAAMM |